221

Technical Committee 101 - Session I /

Comité technique 101 - Session I

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

procedure lasting 7, 14 and 21 days for three series of testing,

specimens were sheared in the shearing stage by the same rate

of shearing. Normal stress levels remained unchanged in both

stages.

3.2

Test results

Measured vertical displacements in the shear stage indicate

consolidation under all normal stress levels and hydration times.

The displacement rate in these tests was 1 mm/min and the

assumption was that compression during the shear would cause

pore pressure inside the specimen to increase.

Table 1 shows the results of testing in the shear stage.

Residual values of shear strength were obtained at specimen

relative deformation of 15%, and this was also the maximum

horizontal shear that could be obtained in the standard shear

box. Shear strength values were constantly growing with the

increase of normal stress and with decrease of final moisture

content. With specimens subjected to stress levels of 50 and 100

kPa, longer hydration times caused higher values of final

moisture content and decreasing shear strengths. With

specimens subjected to stress level of 200 kPa, final moisture

content and shear strength of bentonite did not change

irrespectively on hydration times.

Table 1. Summary of direct shear test results.

Shear strength

Hydration

time

Normal

stress

(kPa)

Peak

(kPa)

Residual

(kPa)

Final moisture

content

(%)

7 days

50

21.4

17.3

113.12

14 days

50

19.4

12.9

124.32

21 days

50

17.2

11.8

140.26

7 days

100

32.2

25.6

85.36

14 days

100

29.2

21.4

97.82

21 days

100

27.5

20.0

104.05

7 days

200

51.1

38.0

71.33

14 days

200

52.0

37.6

69.66

21 days

200

49.4

36.2

71.91

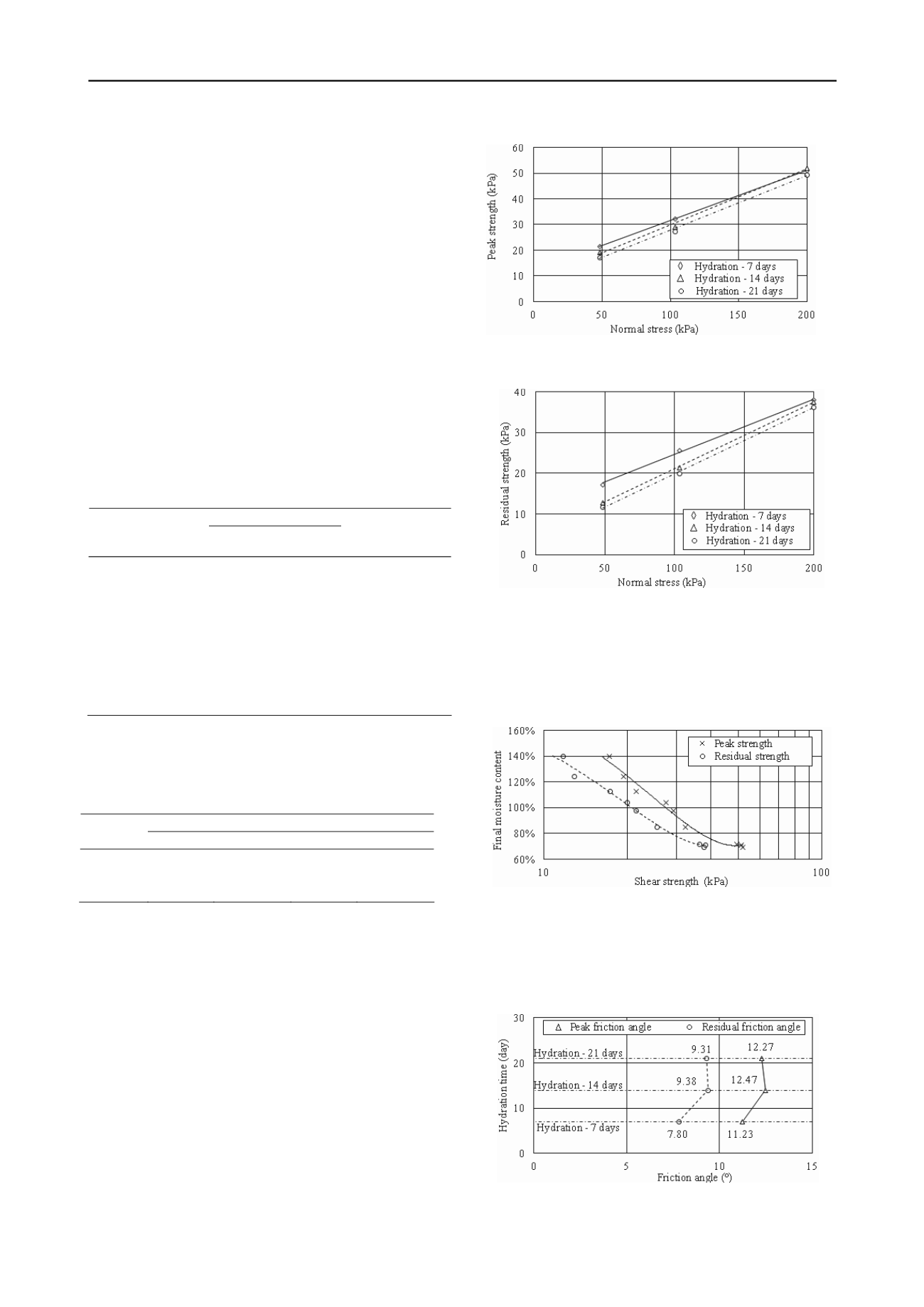

Table 2 shows the value of shear strength parameters obtained

by shearing of bentonite specimens. Peak and residual strength

envelopes are shown in Figures 2 and 3.

Table 2. Shear strength parameters.

Peak parameters

Residual parameters

Hydration

time

c (kPa)

(°)

c (kPa)

(°)

7 days

11.99

11.23

11.05

7.80

14 days

8.04

12.47

4.79

9.38

21 days

6.32

12.27

3.63

9.31

By observing peak (Figure 2) and residual (Figure 3)

strength envelopes, it is evident that the specimens sheared after

14 and 21 days of hydration have almost identical values of

peak and residual friction angle, while peak and residual values

of cohesion were decreasing as specimen hydration times were

increased. In the case of specimen hydrated for seven days,

there was obvious change in behavior, in comparison with

specimens hydrated for 14 and 21 days. This specific specimen

shows significantly higher values for peak and residual cohesion

and somewhat lower values for peak and residual friction angle,

in comparison to specimens hydrated for 14 and 21 days.

Figure 2. Peak strength envelopes.

Figure 3. Residual strength envelopes.

Figure 4 presents the influence of final moisture content on the

test result values for peak and residual shear strength. It is

evident that, irrespectively to the normal stress level, shear

strength has tendency to decrease as final moisture content

increases.

Figure 4. Final moisture content vs. shear strength.

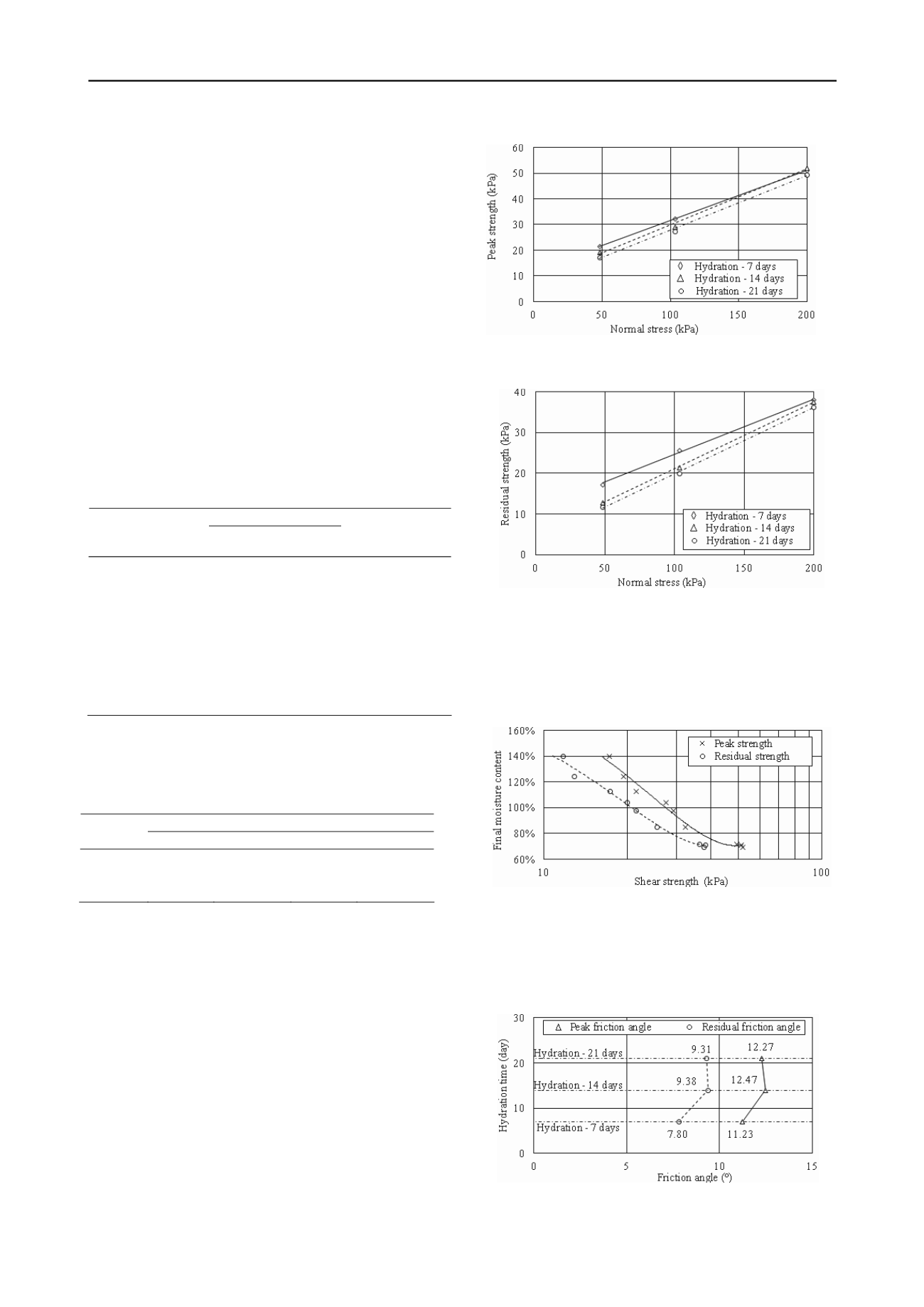

Figure 5 presents the correlation between peak and residual

friction angles and the time of hydration. For hydration times in

this test, a change in the friction angle was visible up to the 14th

day of hydration. After that, the friction angle decreased

insignificantly.

Figure 5. Hydration time vs. friction angle.