208

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

1. MATERIAL TESTED

A systematic experimental investigation of grain crushing for

natural materials is often difficult due to the relatively high

stress required to crush the grains and the variability and

heterogeneity of natural deposits, which makes it difficult to

obtain repeatable results. For these reasons the experimental

work was carried out on an artificial granular material.

The material used is commercially available under the

acronym LECA (Light Expanded Clay Aggregate) and is

obtained through an industrial process. The expanded clay

pellets are screened into their various fractions and made

commercially available both as intact (so-called "granular")

with a characteristic a round shape and a hard outer shell (see

Fig. 1a), or crushed, at different grain sizes (see Figs 1b-c).

(a)

(b)

(c)

Figure 1. LECA pellets whole/broken with particle diameters: (a) d=2-4

mm; (b) 0.71-1 mm; (c) d<0.063 mm (Wanninger and Zwicker, 2010).

The material has a very low apparent unit weight; this is

because the particles are characterised by the existence of a

double order of porosity: "inter-granular", i.e. voids existing

between particles, and "intra-granular", i.e. closed voids

existing within individual particles (see Fig. 2). Because of the

voids existing within the particles, their apparent unit weight,

s

,

depends on their diameter

d

as

s

(

d

) =

a

·(

d

0

/d

)

b

, with

a

= 12.64

kN/m

3

,

b

= 0.268, and

d

0

=1 mm (Casini

et al.,

2013).

INTERPARTICLE

POROSITY

LIGHTWEIGHT AGGREGATE PARTICLE

INTRAPARTICLE

VOIDS

INTRAPARTICLE POROSITY

INTERPARTICLE

VOIDS

SOLID

Figure 2. Inter-granular and intra-granular porosity (after Casini and

Viggiani, 2011).

1.1

Initial grading

The maximum particle size of the tested material was 4 mm; the

material was reconstituted to obtain grading curves with the

same mean diameter

d

50

, and different coefficients of

uniformity,

U

(= 3.5, 7, 14, 28) or the same coefficient of

uniformity,

U

and different

d

50

(= 0.5, 1 mm) (Figure 3).

Figure 3. Grain size distributions of reconstituted LECA samples.

1.2

Basic properties

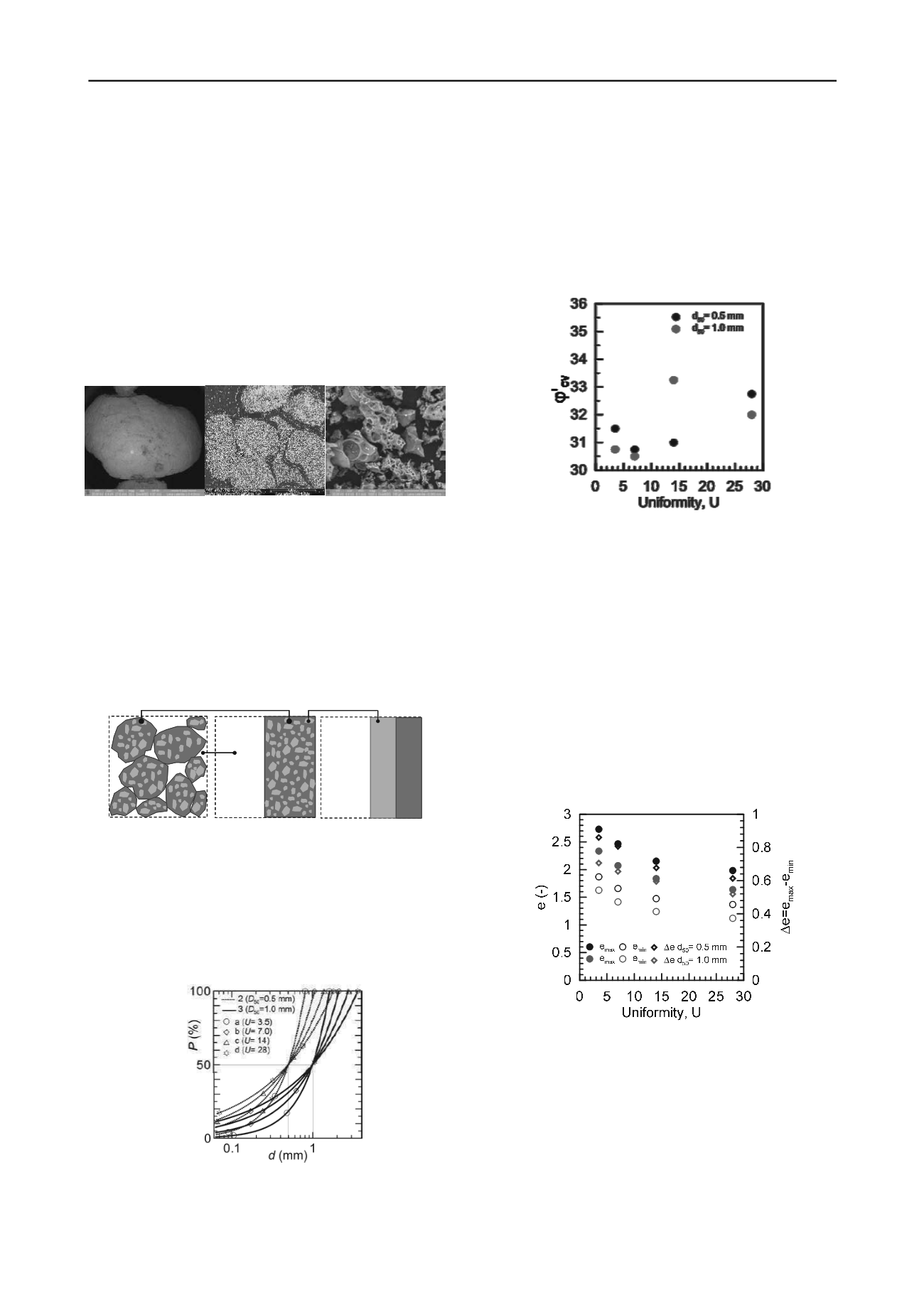

The constant volume friction angle

'

cv

, and the minimum and

maximum densities corresponding to each grading were

determined before testing.

'

cv

was obtained by pouring the

material on a rough, flat surface from a given height, and

measuring the slopes of the resulting granular cone. The

experimental values of

'

cv

(Fig. 4) are in the range of 30-33°

and increase slightly with the coefficient of uniformity. There is

no obvious dependence on the mean grain size.

Figure 4. Constant volume angle of friction as function of uniformity for

crushed LECA

The maximum (e

max

) and minimum (e

min

) voids ratio were

determined using non-standard procedures so that particle

crushing would not falsify the results. In particular, e

min

was

obtained vibrating the samples with very low input energy.

The experimental values of (

e

max

-

e

min

) obtained for the

granular material (Fig. 5) at different values of

U

and

d

50

, of the

order of 0.9 ÷ 1.0, are much larger than those obtained for other

granular materials with grains that do not exhibit significant

intra-porosity, such as natural river sands, lightweight

aggregates and glass ballottini (

e

.

g

. Miura

et al.,

1997). LECA

can probably be reconstituted at very high values of voids ratio

due to the rough surface of the particles of crushed material, as

shown in Figure 1, which causes a very "open" structure with

loads carried by arching between particles, some of which are

effectively unloaded or redundant, and large inter-porosity.

Figure 5. Minimum and maximum void ratios as a function of

uniformity for crushed LECA

1.3

Microstructural features

Examples of Scanning Electron Microscopy (SEM)

micrographs of crushed LECA particles of different dimensions

are reported in Figure 6a-b. SEM micrographs of portions of

grains belonging to different fractions were manipulated using

the image editing program GIMP (Peck, 2008); the exposed

intra-granular pores were coloured progressively in black and

the contrast in the image was raised until all the pixels were

either black (pores) or white (matrix),(compare Figures 6a and