3458

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

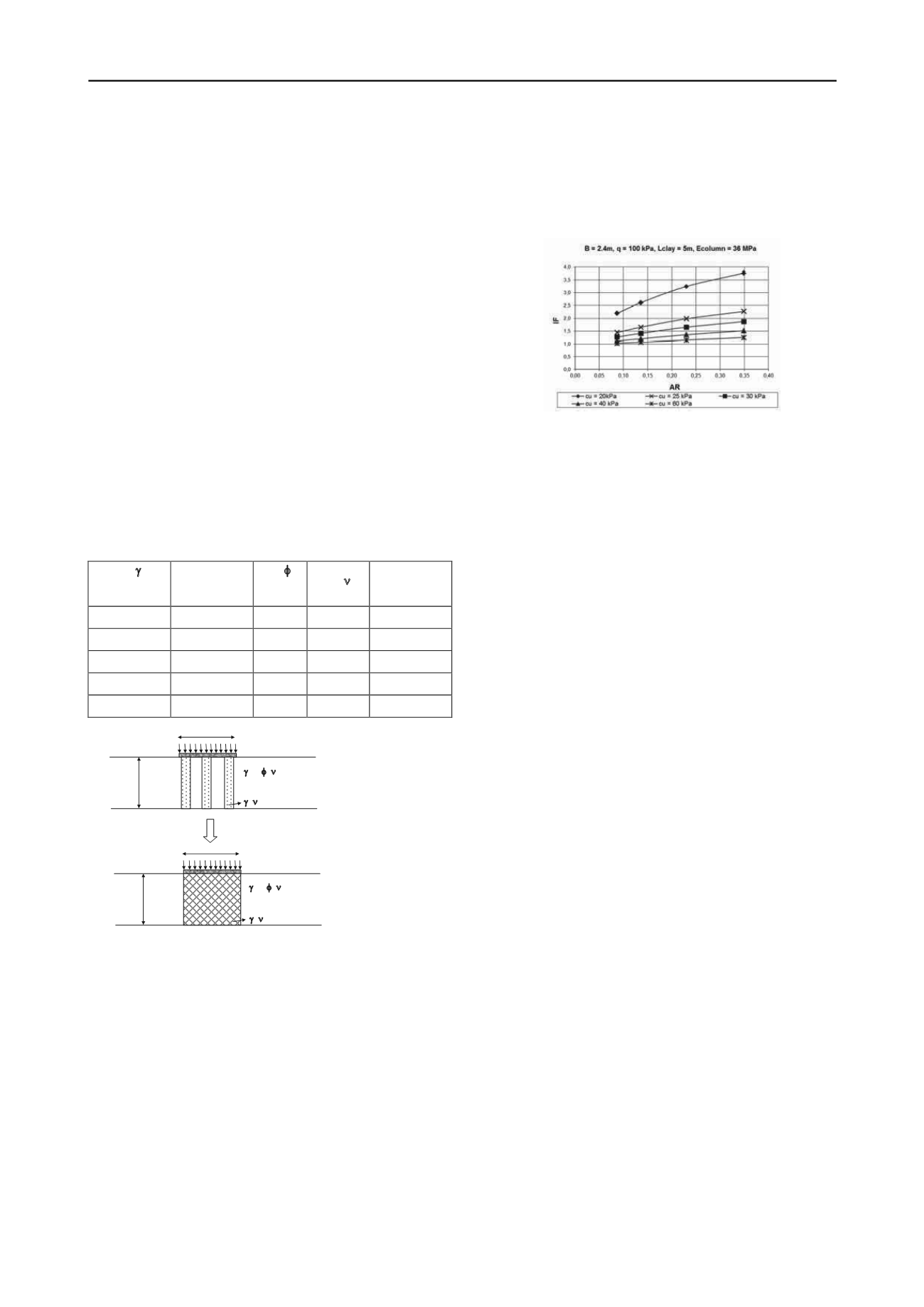

3 DETAILS OF THE PARAMETRIC STUDY

Once the 3D finite element model (Composite Soil Model) to be

used for the analysis of rigid footings resting on rammed

aggregate piers was calibrated using the results of full-scale

load tests as presented in the previous chapter, the next step is to

carry out a parametric study using this finite element model to

investigate the effect of both geometric parameters (area ratio of

rammed aggregate piers, foundation load, width of foundation,

rammed aggregate pier length) and material parameters

(strength of foundation material, modulus of elasticity value of

rammed aggregate piers) on the settlement improvement factor.

Three different footing sizes (2.4mx2.4m, 3.6mx3.6m and

4.8mx4.8m) were used for the parametric study. The thickness

of the compressible clay layer under these footings was varied

as Lclay = 5m, 10m and 15m for each different footing size.

Four different area ratios (AR= 0.087, 0.136, 0.230 and 0.349)

were used for the rammed aggregate pier groups under each

different footing and compressible layer combination.

Foundation pressures, q, were selected as q=25-50-75-100-125-

150 kPa. Schematic representation of these parameters can be

seen in Figure 11. The strength and deformation modulus values

of the compressible clay layer were varied as shown at Table 2.

The deformation modulus value of the rammed aggregate piers

were selected as E

column

= 36 MPa and 72MPa.

Table 2. Strength and deformation properties of the compressible clay

layer used in the parametric study.

(kN/m

3

)

c

(kN/m

2

)

(°)

E

clay

(kN/m

2

)

18

20

0

0.35

4500

18

25

0

0.35

5625

18

30

0

0.35

6750

18

40

0

0.35

9000

18

60

0

0.35

13500

Figure 11 Schematic representation of composite soil model

For each case, first the untreated case is analyzed by

modelling the uniformly loaded rigid footing on compressible

clay using PLAXIS 3D Foundation. Untreated soil settlements

were obtained by this way. Next, the rigid footings resting on

rammed aggregate piers were modeled by PLAXIS 3D

Foundation using the Composite Soil Block approach that was

explained in detail in the previous section. Once the settlement

values for the footings resting on rammed aggregate pier groups

are calculated using this method, settlement improvement

factors are calculated as:

IF = s

untreated

/ s

treated

(1)

where:

IF = settlement improvement factor

s

untreated

= settlement of rigid footing resting on untreated soil.

s

treated

= settlement of rigid footing resting on soil treated

with rammed aggregate pier group.

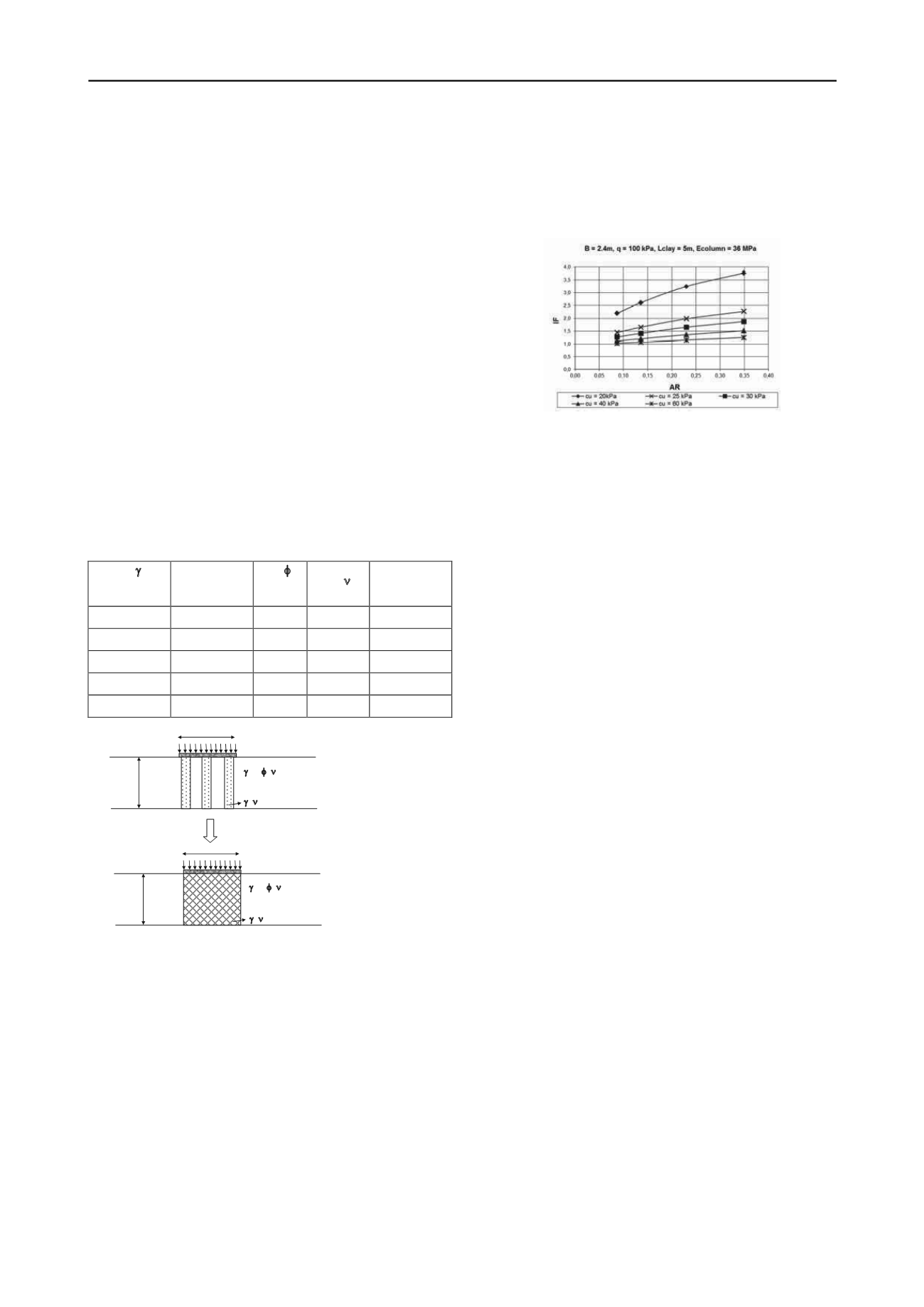

The results of the parametric study detailed in this section

are presented as design charts at Kuruoglu (2008). A sample

design chart is shown in Figure 12. The design charts can be

used to decide on the necessary area ratio of rammed aggregate

piers for a target settlement improvement ratio for footings on

compressible soils resting on rammed aggregate pier groups.

Figure 12. Settlement improvement factor (IF) vs. area ratio (AR) charts

for a rigid square footing (B=2.4m) with a foundation pressure of

q=100 kPa resting on end bearing rammed aggregate piers

(L=5m, E=36 MPa)

As a result of the parametric study, it was found that, the

settlement improvement factor increases as the area ratio, pier

modulus and footing pressure increase. On the other hand, the

settlement improvement factor is observed to decrease as the

undrained shear strength and thickness of compressible clay and

footing size increase.

4 CONCLUSIONS

A simplified 3D finite element model (Composite Soil Model)

calibrated with the results of full scale load tests was developed,

which shows that 3D models for estimating settlement

improvement factor for foundations resting on rammed

aggregate piers can be much simplified by modeling the area

under the footing as a composite soil block with equivalent

linear elastic soil properties, taking the stiffness increase around

the piers during the installation process into account. It is to be

mentioned that the model should be used cautiously for floating

pier groups with pier lengths less than 1.5B (B = width of the

footing), especially at high surface pressure levels , i.e. q / qult

> 0.5, where qult = ultimate bearing capacity of the native soil.

Using this simplified model, design charts for settlement

improvement factors of square footings of different sizes

(B = 2.4m to 4.8m) resting on aggregate pier groups of different

area ratios (AR = 0.087 to 0.349), pier moduli

(Ecolumn = 36MPa to 72MPa), and with various compressible

clay layer strengths (cu = 20kPa to 60kPa) and thicknesses

(L = 5m to 15m) were prepared.

As a result of the parametric study, it was found that, the

settlement improvement factor increases as the area ratio, pier

modulus and footing pressure increase. On the other hand, the

settlement improvement factor is observed to decrease as the

undrained shear strength and thickness of compressible clay and

footing size increase.

5 REFERENCES

Handy R.L. 2001. Does lateral stress really influence settlement.

Journal of Geotechnical and Geoenvironmental Engineering

127

(7), 623-626.

Kuruoglu O. 2008. A new approach to estimate settlements under

footings on rammed aggregate pier groups.

Thesis presented to the

Middle East Technical University in partial fulfillment of the

requirements for the degree of Doctor of Philosophy

. Ankara,

Turkey.

Özkeskin A. 2004. Settlement reduction and stress concentration factors

in rammed aggregate piers determined from full scale load tests.

Thesis presented to the Middle East Technical University in partial

fulfillment of the requirements for the degree of Doctor of

Philosophy

. Ankara, Turkey.

L

clay

L

clay

Rigid Base

Rigid Base

B x L

B x L

q

q

Clay layer

, c,

,

, E

clay

Clay layer (Mohr-Coulomb Model)

, c,

,

, E

clay

Rammed Aggregate Pier

,

, E

column

, AR

Composite Soil Block (Linear Elastic Model)

,

, E

composite