3097

Technical Committee 301 /

Comité technique 301

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

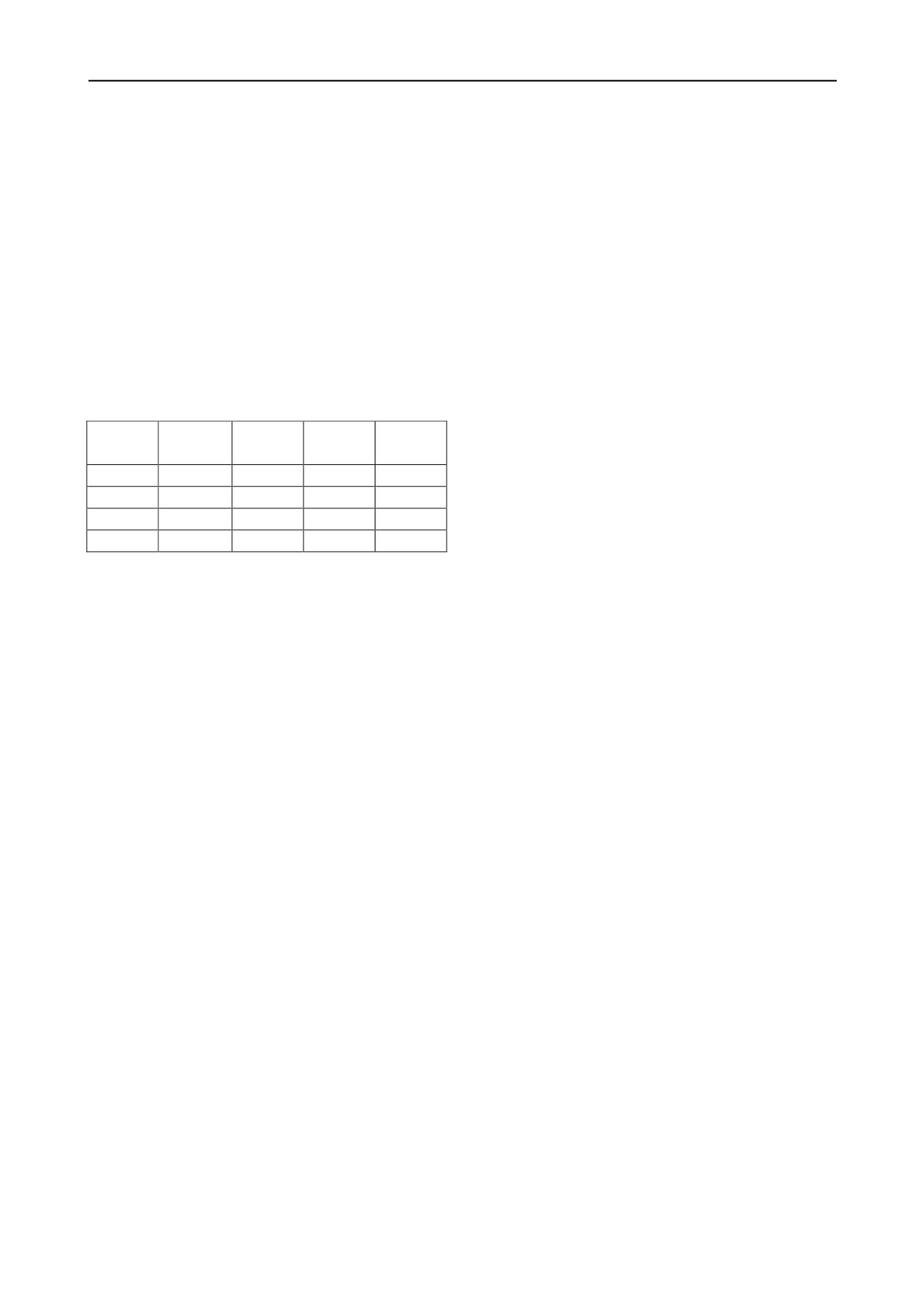

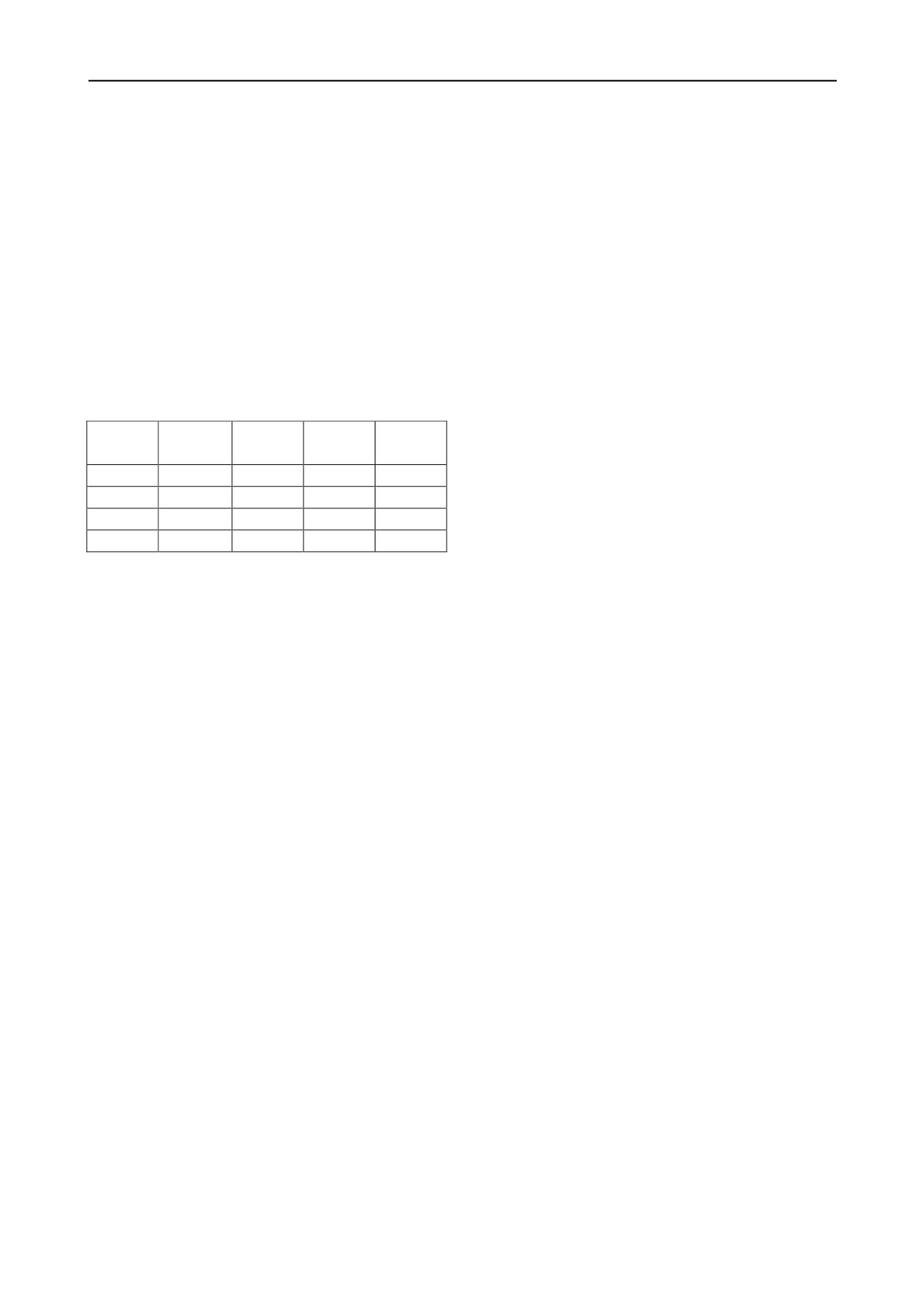

5MIXING TEST OF SLAKED LIME-SOIL AND RESULTS

Table 1 shows the proportions of material soils to be prepared

and slaked lime to be mixed for them. In Table 1, item “sand”

means excavated sandy soil which was used at the tower’s

erection. Each mixed soil is mixed this “sand”, clayey soil and

lateritic soil with weight ratio in Table 1. Slaked lime, which is

a stabilizing material, is added to the mixed soil 1 at rates of

Table 1. The mixing purpose of clayey soil is expected the

stabilized effect with chemical reaction of clay minerals and

slaked lime. Also, on lateritic soil mixing, it is intended that the

ferromagnetic ion and aluminum ion in it will promote chemical

hardening reactions. Grain size accumulation curves of mixed

soils are shown in Fig.3. Results of the test were evaluated by

comparison of unconfined compression strengths on treated

specimens.

Table 1. Proportion of mixed soil

items

sand

(excavated

sandy soil)

clayey soil lateritic soil

slaked lime

mixture rate

(%)

mixture A 100

0

0

5, 10, 15

mixture B

85

15

0

5, 10, 15

mixture C

70

30

0

5, 10, 15

mixture D

70

15

15

5, 10, 15

1) Unconfined compression strengths of treated specimens

were increased as the mixing rates of slaked lime were

increased.

2) The unconfined compression strengths and the

deformation moduli of tested specimens increased with their

curing times, and proportional relation between them was

recognized. Relation between the curing time and the

unconfined compression strength on mixed soil D is shown in

Figure 5.

3) The changes of their dry densities by curing time were not

recognized.

Figure 5. Relation of unconfined compression strength and curing time

Based on above-mentioned results, the material soil used for

the foundation platform and its base ground was a mixture of

three different soils of the original sandy soil, clayey soil and

lateritic soil at weight ratios of 70%, 15% and 15%( mixing soil

D proportion). Slaked lime, which was a stabilized material,

was added to the mixed soil 1 at a rate of 0.1.

6CONSTRUCTION PROCEDURE AND UTILIZATION OF

GEO-TEXTILE

It is decided that mixed soil D proportion should be used for

material soil and slaked lime should be used for a stabilized

material at adding to the mixed soil 1 at a rate of 0.1. The

construction method will be applied by tamping method.

The construction procedure on jobsite is as follows.

1) The material soil treated by slaked lime should be spread

at 15 cm of its thickness, after then it should be compacted to a

thickness of about 7.5cm. By the repeat of this work, the base

ground should be developed to the designated level.

2) Compacting work is decided by the field trial work to be

composed of 3 steps. Primary compaction should be conducted

using a wooden rod (dia.3cm) with man power’s tamping, and

followed by secondary compaction using a flat steel plate

(15cm×15cm×1cm) as the same manner. Finally, surface

compaction should be conducted by using of a tamping rammer.

3) The designated base ground for the tower will be made of

laminated structure with 7cm thickness tamping layers. Since

there is a smooth surface among each layer, its existence may

make a week point on the mechanical standpoint. In order to

secure the bond of each layer, roughening work for each

compacted surface should be done before tamping of the next

layer. The surface roughening work should be performed by

using of steel rakes with manpower.

When allowable bearing capacity is 1.2MN/m

2

, it is assumed

that the compressive strength in-place should be about 60

percent of the strength obtained in the laboratory test. This

means that the target value should be 2 MN/ m

2

. In the case of

mixed soil D, it would be take a curing time of more than 90

days to achieve a value of 2MN/m

2

. However, since the

reconstitution work for the superstructure will be needed to be

executed without waiting 90days, some measure to reinforce the

improved soil should be needed until the onset of its strength.

As above-mentioned consideration, it is decided that Geo-textile

should be applied for temporally reinforcement of improved

soils until the onset of its strength.

The designing study was preceded on a section of base

ground in Figure 6 which spread and inserted 3 layers of

Geotextile. Table 2 shows the specification of Geotextile which

was utilized. One of the effects of Geo-textile is to work as

reinforced materials of shear resistance for soil mass. When

using this effect for the designing base ground, it is expected

that it increases safety factor to the sliding failure by about 20

percent.

Figure 6. Section of spreading Geo-textile