2491

Technical Committee 211 /

Comité technique 211

investigate enzymatic ureolytic CaCO

3

precipitation in a finer

grained material. The specimen was prepared in the same

manner as described for the triaxial columns for the Ottawa 20-

30 sand. The cementation fluid for the first of the two

applications contained approximately 2.0 g/L enzyme, 400 mM

urea (reagent grade, Sigma-Aldrich), 300 mM CaCl

2

-2H

2

O

(laboratory grade, BDH) at pH=7.7. The fluid for the second

application contained 1 M urea-CaCl

2

-2H

2

O solution at pH=7.8

without any enzyme. After the test, the triaxial specimen was

washed and subject to acid digestion in the same manner as the

Ottawa 20-30 triaxial specimens.

3. RESULTS

3.1

Acrylic Tubes

Approximately 100 ml of cementation solution was delivered

per application for the first application in each acrylic tube.

However, the amount of solution the tube would accept was

notably reduced in subsequent applications, when less than 75

ml was typically required to fill the tubes to ≈ ½ inch (12 mm)

above soil line. At the conclusion of the experiment,

precipitation was visible along the entire length of tubes 1 and

2. Internally the cementation was variable, with some highly

cemented zones and other zones with little to no cementation.

Tube 1 yielded mostly small, loose chunks of sand with

strong effervescence upon digestion. Most of this column

appeared un-cemented and exhibited unusually viscous behavior

when wet. A fairly large (compared to column diameter) piece

of strongly cemented sand (not breakable without tools) formed

in the deepest layer of tube 1. Tube 2 had many small chunks

of weakly cemented sand with strong effervescence upon

digestion. Tube 3 had little to no precipitation in the top layer

(i.e. this layer did not show any indication of carbonate upon

acid digestion.) The deepest layer of tube 3 contained many

pieces of weakly cemented sand that effervesced strongly upon

digestion. The middle layer of tube 3 contained a few pieces of

cemented sand that effervesced moderately upon digestion. The

results from the acid washing are presented in Table 1.

Table 1. Results from

Experiment Set 1

using 20-30 Ottawa silica sand

Summary of Results

Tube #

Layer

Weight

Change via

Digestion

Amt.

of

CaCO

3

(g)

Total

Amt.

CaCO

3

(g)

Theor.

Max

CaCO

3

(g)

1

11%

3.57

2

3.8%

1.67

3

2.7%

1.73

4

2.1%

1.40

5

2.3%

1.74

1

6

2.0%

1.64

11.8

≈14.5

1

0.76%

0.63

2

0.65%

0.69

2

3

0.49%

0.75

2.07

≈ 4.35

1

0.23%

0.31

2

0.58%

0.63

3

3

1.7%

2.63

3.57

≈ 4.35

The theoretical maximum CaCO

3

content is the stoichiometric

maximum balanced on initial concentrations. The primary

experimental differences between the tests are (1) the number of

applications of cementation fluid and (2) the manner in which

the urease was delivered. The results indicate that there is

greater carbonate precipitation with increasing number of

applications, as expected. The data show more precipitation in

(or on) the top layer of tubes 1 and 2 but not in tube 3, as the

enzyme was physically confined to the lower-third layer in tube

3 during sample preparation. In the top layer of tube 3, where no

urease was mixed with the sand, carbonate precipitation was

nearly undetectable. There was no visual evidence of

precipitation and practically no measurable change in weight of

this layer after acidification (weight change = 0.23%). In the

bottom layer of tube 3, where 3 g of dry enzyme was mixed

with the soil, there was a weight change of 1.7% following acid

washing. The middle layer of this specimen had a minor change

in weight (0.58%), possibly due to uneven distribution of the

layers during preparation or splitting of the specimen or to

upward migration of urease from the bottom layer.

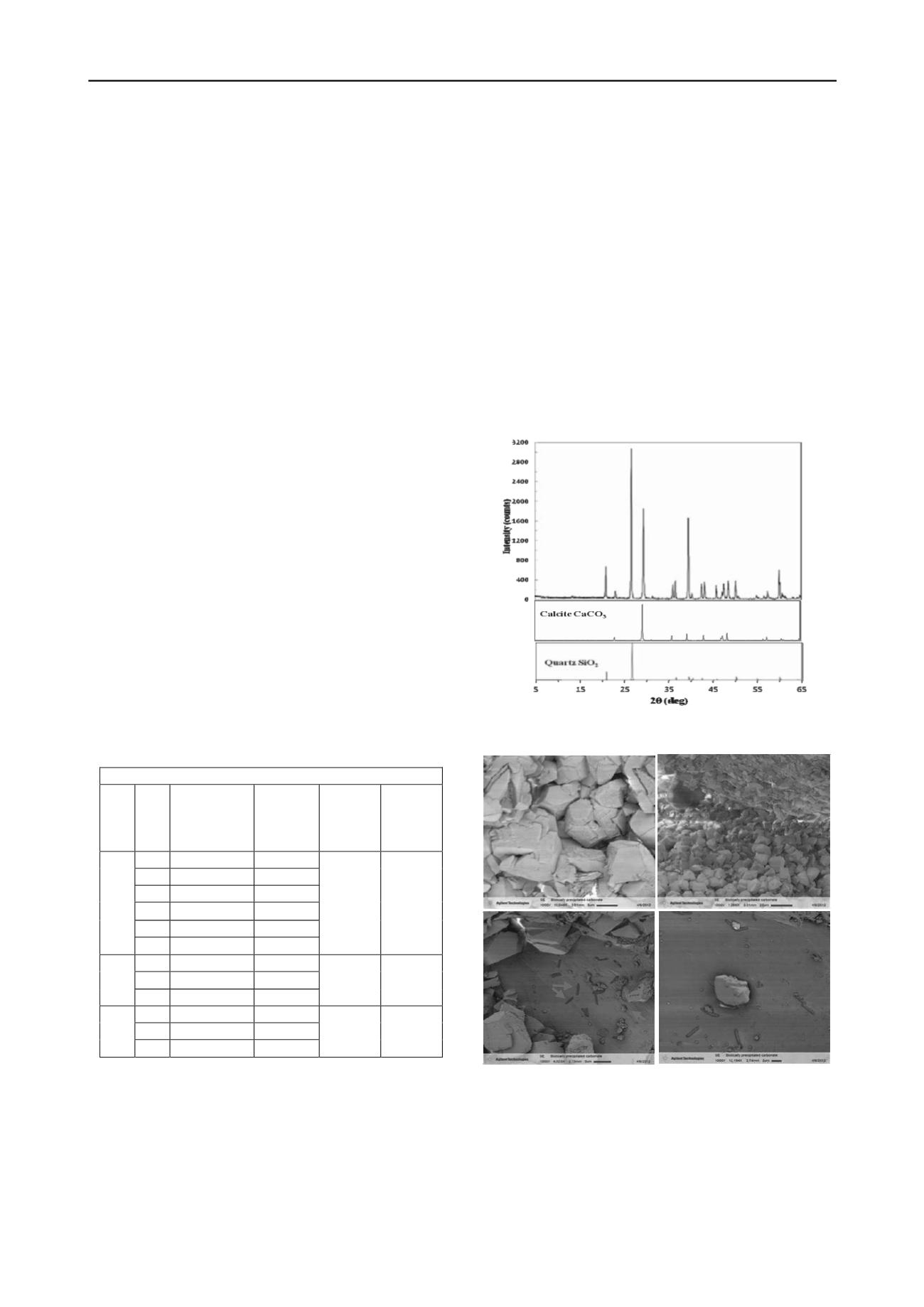

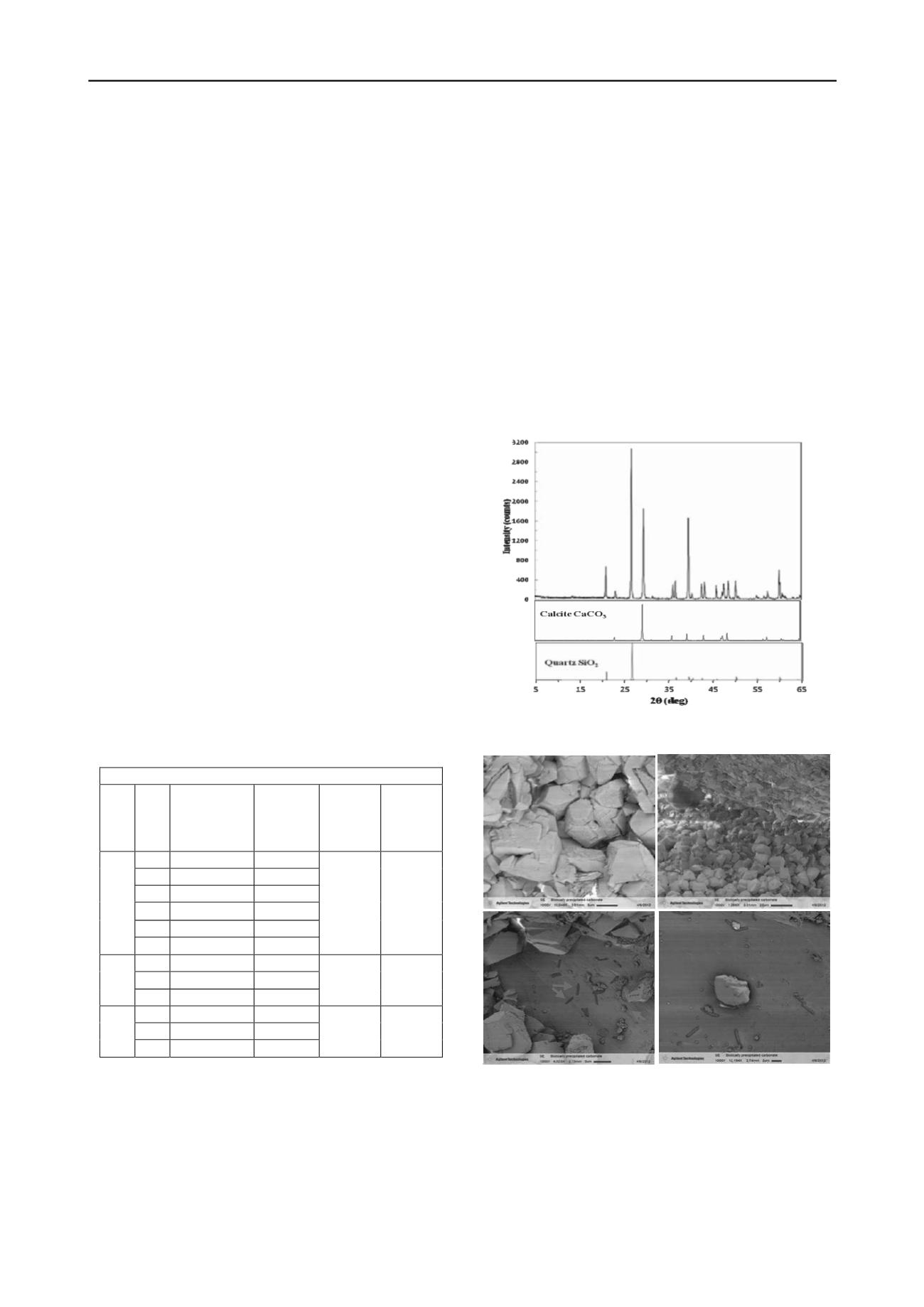

XRD analysis, presented in Figure 1, confirms that calcite is the

mineral phase present in the cemented soil chunks. LV-SEM

images, presented in Figure 2, show silica (quartz) sand

particles cemented with calcium carbonate and various

morphological features associated with the cementation process

on the silica surface.

Figure 1. XRD results from cemented sand sample (top plot). Quartz &

calcite standards (middle & bottom plot, respectively).

B

A

C

D

Figure 2. LV-SEM images a.) Well-grown and cementing calcite crystals;

b.) Cementing calcite crystals at inter-particle contact; c.) Indention of quartz

surface (blue arrows) and nucleation of calcite crystals (red arrows); d.) Calcite

crystal growing on quartz surface.

3.2 Triaxial Columns

The three triaxial sand columns (2 Ottawa 20-30 sand columns

and 1 Ottawa F-60 sand column) were tested in drained triaxial

compression prior to acid digestion. All three columns were

able to stand upright after removal of the split mold. The results