2488

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

5

SUMMARY AND CONCLUSION

The total and effective stress analysis on two tested piles driven

in improved ground of Thi Vai Port is performed and

summarized as:

0

5

10

15

20

25

30

0

500

1,000 1,500 2,000

SHAFT RESISTANCE (KN)

DEPTH (m)

Sandy silt and silt

Eq. 8

Eq. 9

β = 0.3

P

I

L

E

2

2

m

P

I

L

E

1

6

m

Sand

Clay

For total stress approach, the analysis indicates the

alpha method with a reduction coefficient

incorporated into the API 1987 edition gave the best

agreement.

For effective stress approach, the analysis shows the

Eslami and Fellenius method (1997) is approximately

the same as the measurements.

For two approaches, the total stress approach is the

better agreement.

Correlation coefficient, N

KT

, between CPTU pore

pressure adjusted cone stress and vane shear stress is

about 18.

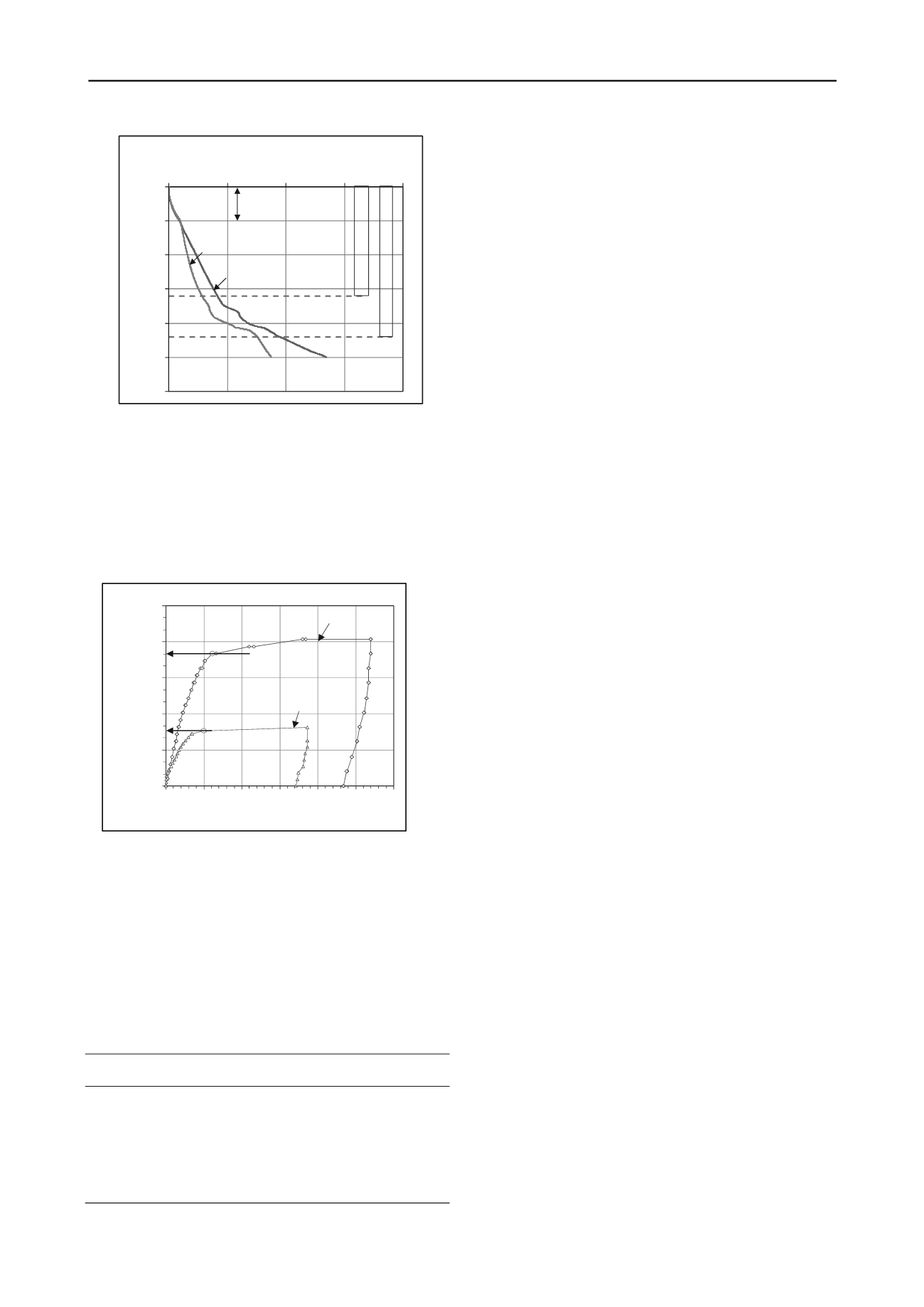

Figure 9. The accumulated shaft resistances versus depth

6

REFERENCES

1.2

Pile test results and evaluation of approaches

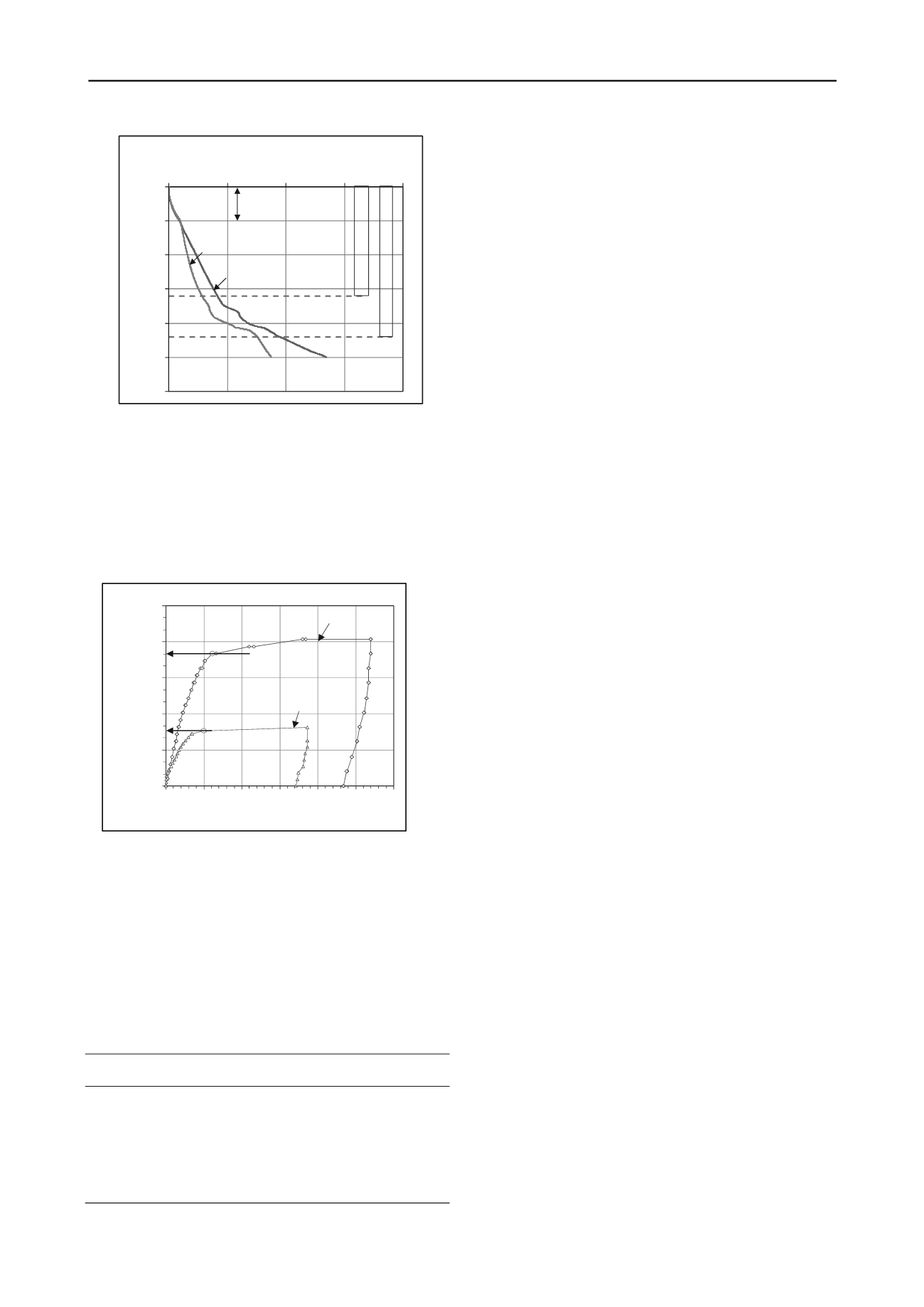

The static loading tests for the 22 and 16 m Pile were performed

after piles driven about 23 and 14 days, respectively. The 22

and 16 m were tested on September 29, 2011 and November 22,

2011. The load-movement curves of the two tested piles in

Figure 12 indicate the ultimate loads of the plunging failures at

1,100 and 459 KN, respectively.

API (1987) Recommended practice for planning, designing, and

constructing fixed offshore platforms, API RP2A, 17th edn.

American Petroleum Institute, Washington.

API (1993) Recommended practice for planning, designing and

constructing fixed offshore platforms—working stress design, API

RP2A, 20th edn. American Petroleum Institute, Washington.

Cai G., Songyu L., Liyun T., Guangyin D. 2009. Assessment of direct

CPT and CPTU methods in predicting the ultimate bearing capacity

of single piles.

Eng Geol

104:211–222,.

0

300

600

900

1,200

1,500

0 5 10 15 20 25 30

LOAD (KN)

MOVEMENT (mm)

Pile 16

m

Pile 22 m

1,100 KN

459 KN

Eslami A., Fellenius B.H. 1997. Pile capacity by direct CPT and CPTu

methods applied to 102 case histories.

Can Geotech J

34:886–904.

Fellenius B.H. 2008. Effective stress analysis and set-up for shaft

capacity of piles in clay.

ASCE Geotechnical Special Publication,

GSP

180:384-406.

Karlsrud K., Haugen T. 1981. Cyclic loading of piles and pile anchors,

field model tests at Haga. Norwegian Geotechnical Institute

Research Report.

Kolk H.J., van der Velde E. 1996. A reliable method to determine the

friction capacity of piles driven into clays. In: Proceedings of the

28th annual offshore technology conference, Houston, pp 337–346.

Lunne, T., Christoffersen, H.P. and Tjelta, T.I. 1985. Engineering use of

Piezocone data in North Sea Clays. Proceedings XI ICSMFE, San

Francisco.

Murff D. 1980. Pile capacity in a softening soil. Int J Numer Anal

Methods Geomech 4:185–189.

Figure 10.

Pile-head load-movement curves of two static

loading tests performed on 22 and 16 m pile.

Randolph M.F., Murphy B.S. 1985. Shaft capacity of driven piles in

clay. In: Proceedings of the 17th annual offshore conference,

Houston, pp 371–378.

Normally, the plunging failures of the test piles are found

when the pile toe is in soft clay as in the subject case and the

pile toe resistance can be disregarded when evaluating the

analysis methods. Performance of two approaches are evaluated

basing on ratio of the estimated capacities, Qp, to the measured

capacities, Qm. Table 1 shows the performance evaluation of

two approaches for the measured pile capacities.

Semple R.M., Rigden W.J. 1984. Shaft capacity of driven pipe piles in

clay. In: Proceedings of the on analysis and design of deep

foundations, San Francisco, pp 59–79.

Takesue, K., Sasao, H., Matsumoto, T. 1998. Correlation between

ultimate pile skin friction and CPT data.

Geotechnical Site

Characterization (2)

: 1177-1182. Rotterdam: Balkema.

Table 1.

Evaluation on performance of the total and effective

pproach for predicting the pile capacity.

a

Pile 16 m Pile 22 m

(Qp/Qm) (Qp/Qm)

Total stress approach

Eq. 1

0.967

0.949

Eq. 4

1.422

1.416

Eq. 5

1.048 1.280

Eq. 6

1.203 1.423

Effective stress approach

Eq. 8

0.915 0.884

Eq. 9 0.624 0.688