2499

Technical Committee 211 /

Comité technique 211

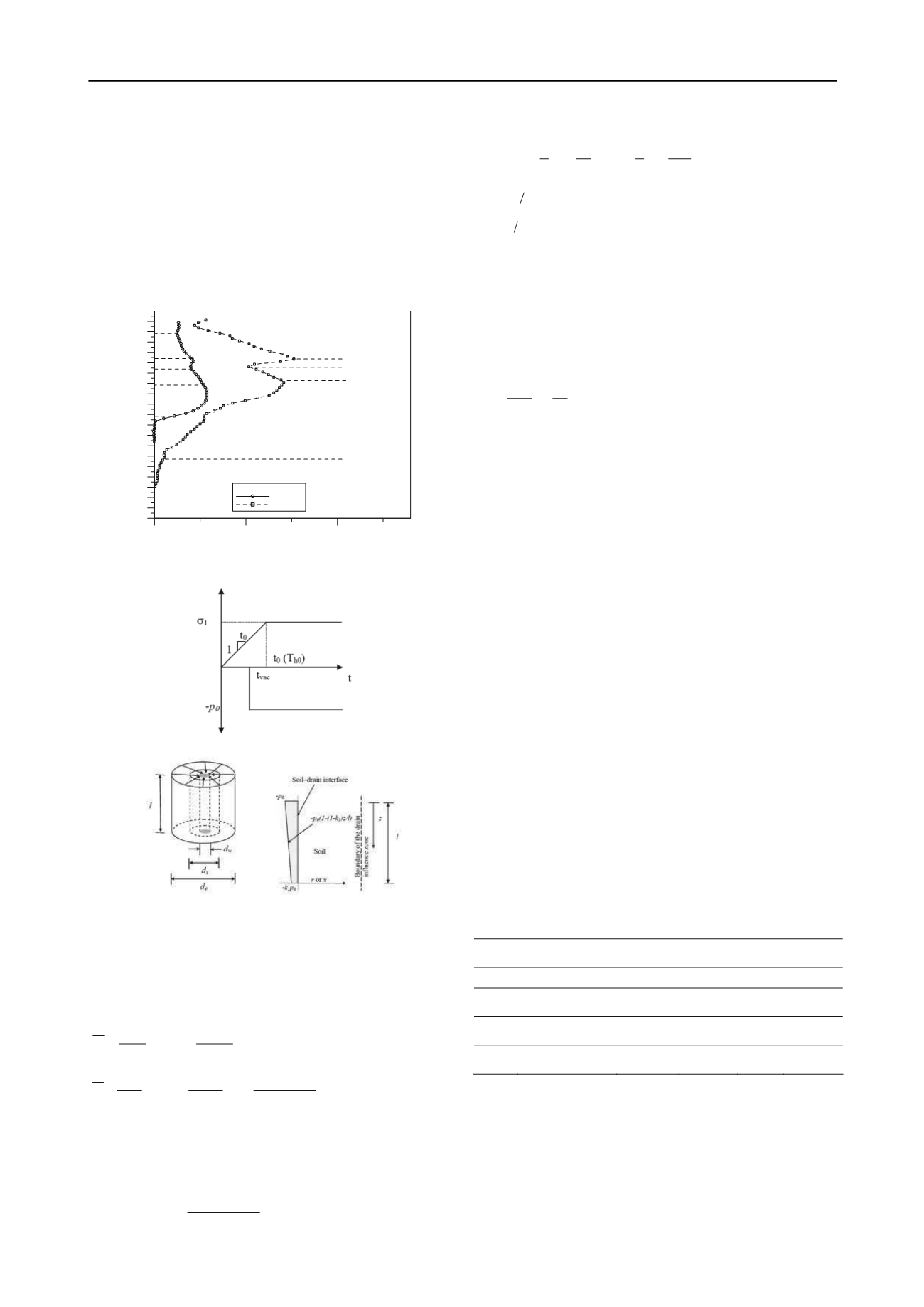

surcharge preloading. during embankment construction, the

surcharge fill is increased at a prescribed rate to reach the

desired height. therefore, the time-dependent loading due to the

filling would be more realistic than an instantaneous loading,

especially during the stages of embankment construction. in this

section, the embankment load is assumed to be a ramp loading:

i.e., the embankment load (

t

) increases linearly with time up to

a maximum value (

within time

t

0

and is constant thereafter

(fig. 4a). the vacuum is applied at

t=t

vac

. figure 4b shows the

unit cell adopted for analytical solutions with boundary

conditions (fig. 4c).

0

1

2

Lateral displacement/Total change in applied stress

(mm/kPa)

-30

-28

-26

-24

-22

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

2

4

6

8

10

Depth (m)

Section/Plate No.

VC1/MS28

WD3/MS27

Platform

Platform

Dredged mud

Dredged mud

HS

Holocene sand

UHC

Upper Holocene Clay

LHC

Lower HoloceneClay

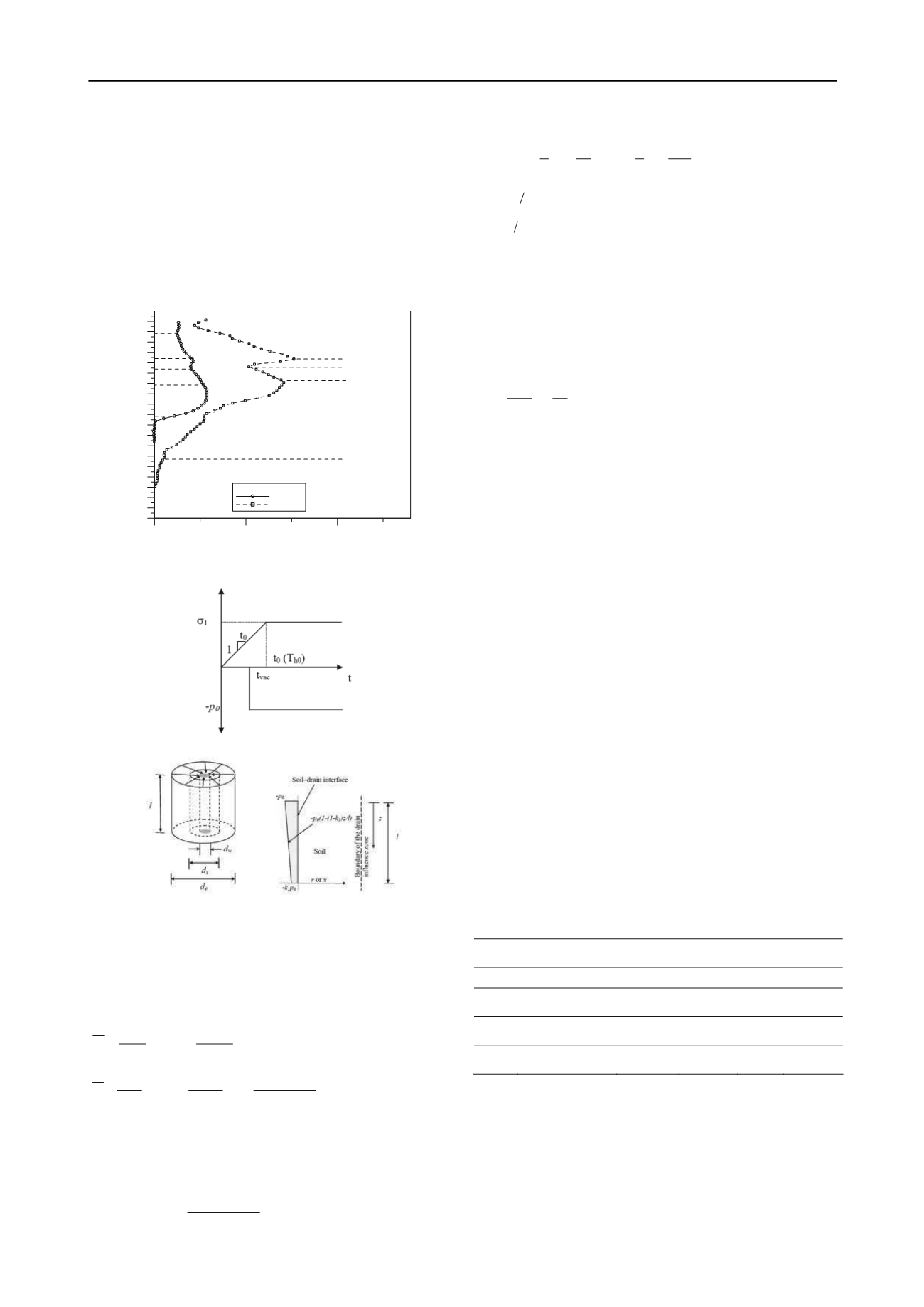

figure 3. comparison of lateral displacements at the embankment toe in

vacuum and non-vacuum area after 400 days (indraratna et al. 2011)

(a)

(b)

(c)

figure 4. (a) time-dependent surcharge loading, (b) unit cell including

smear zone, and (c) boundary conditions with vacuum distribution (after

indraratna et al. 2011)

the excess pore pressure due to radial consolidation

considering smear effect under time-dependent surcharge can be

expressed by (indraratna et al. 2011):

0

1

2

0

2

0

8

exp 1

8

t t

for

d

tc

tc

d u

e

h

h

e

L

(1)

0

1

2

0

2

0

0

2

8

exp

8 exp 1

8

t t

for

d

t t c

d

tc

tc

d u

e

h

e

h

h

e

L

(2)

recently, indraratna et al. (2005) proposed that the excess

pore pressure dissipation due to vacuum pressure alone could be

determined from:

vac

vac

t t

u

,0

(3)

vac

e

vac

h

vac

t t

p

d

t t c

p

u

,

8

exp

0

2

0

(4)

2

3

2

4

3

ln

ln

l

q

k

s

k

k

s

n

w

h

s

h

(5)

w e

d d n

(6)

w s

dd s

(7)

where,

= the diameter of soil cylinder dewatered by a drain,

d

s

= the diameter of the smear zone, d

w

= the equivalent diameter

of the drain, k

s

= horizontal soil permeability in the smear zone

and q

w

= drain discharge capacity.

e

d

the excess pore pressure at a given time

t

can calculated

based on the equations (2) to (7). for normally consolidated

clay, the settlement (

) can now be determined by the following

equation:

i

c

e

HC

'

'

log

1

0

(8)

where,

= settlement at a given time,

C

c

= compression index,

and

H

= compressible soil thickness.

in order to calculate excess pore pressures and associated

settlements, equations (1)-(8) are employed using parameters in

table 2. for the completely remoulded dredged mud that was

reclaimed from the seabed and the Upper holocene sand the

ratio

k

h

/k

s

was assumed to be unity. for the upper and lower

holocene clay, the ratios of

k

h

/k

s

and

d

s

/d

w

were 2 and 3,

respectively, in accordance with the laboratory obsevrvation

decribed by indraratna and redana (1998).

the embankment load was applied according to a staged

construction (unit weight of 20 kn/m

3

). settlement and

associated excess pore pressure predictions were calculated at

the embankment centreline using eqs. 1-8. it is noted that, at the

beginning of each subsequent stage, the initial in-situ effective

stress was calculated based on the final degree of consolidation

of the previous stage. in vacuum areas, a suction pressure of 65

kpa was employed.

figures 5 and 6 present the predicted settlement and

associated excess pore pressure with the measured data in areas

Wd1 and Vc1, where the total applied load (vacuum and

surcharge =120-130kpa) and clay thickness (20-23m) are

comparable. overall, the comparisons between prediction and

field observation show that the settlement and associated pore

water pressure can be predicted very well. in vacuum areas, the

degree of consolidation was more than 90% after 13 months,

whereas that in the non-vacuum area was less than 85%. this

confirms that, at a given time, the vacuum combined preloading

would speed up consolidation compared to a surcharge

preloading alone. this is because in non-vacuum areas, a staged

embankment construction had to be adopted to avoid any

undrained failure in the remoulded dredged layer.

table 2. soil properties for each layer

Soil

layer Soil type

Cc/(1+e

0

)

c

h

(m

2

/yr)

k

h

/k

s

s=d

s

/d

w

1

dredged mud

0.235

1

1

1

2

Upper holocene

sand

0.01

5

1

1

3

Upper holocene

clay

0.18

2

2

3

4

lower

holocene clay

0.2

1.9

2

3