2503

Technical Committee 211 /

Comité technique 211

characterized as having ll=50~60, pl=20~30, pi =20~30,

nmc=20~35%. according to Unified soil classification

system (Uscs), the soil in this layer is mostly plastic-silty clay

of low plasticity (cl), though a few samples were found to be

clay of high plasticity (ch). on the Uscs chart, the data points

lie just above a-line. the dry unit weight varied in the range of

13~15 kn/m

3

and the range of void ratio was 0.80~1.20. the

variation of these properties can be seen from figure 3. the

layer also has some organic content is about 1.4~4.0%. the

values of the coefficient of consolidation in the vertical

direction, c

v

were mostly within 3.1 to 25.2 m

2

/year and at

some location as low as 0.79 m

2

/year.

4 desiGn of GroUnd improVement method

it was decided by cpa, that the project will be carried out by

local contractors. therefore, capacity, experience, equipments

etc. of local contractors were to be considered in the design of

the yard. furthermore, ground improvement was to be

completed for the entire project site within one year. hence, the

area was divided into four blocks and time for improvement for

each block was 3 months. an area adjacent to the north

boundary of the site was earlier developed for similar purpose,

by a foreign contractor, where dynamic temping was used for

ground improvement and interlocking block pavement was

made. to keep similarity with the earlier part, interlocking

block pavement was decided for this yard too.

the presence of very soft to medium stiff silty clay at

various locations within the site indicated strong possibility of

substantial total and differential settlement unless effective

measures for improvement of sub-soil are undertaken before the

construction of pavement for the container Yard. therefore,

effective measures for improvement of sub-soil before the

construction of pavement were considered essential in order to

avoid/minimize future problems.

the necessity and extent of the ground improvement

measures are judged with an objective to reduce the differential

settlement and maintenance operations considering the

maximum load from stacking of containers on the entire area

(i.e. p= 52 kn/m

2

). it should be understood that a solution, for

which there will be no future settlement, will lead to high cost

and time for completion and thus may not be practical. the load

on the rtG tracks from the gantry is estimated to be 77.5

kn/m

2

. the extent of improvement and design of pavement

system at the site is targeted to keep maintenance option with

minimal disruption. for rtG and rmG tracks and other

facilities, suitable deep/shallow foundations will be considered

so that they do not undergo relative settlement with respect to

jetty top.

five alternatives, that appeared to be feasible for local

contractors, were assessed. these are- (i) preloading (ii) sand

drain with surcharge (iii) pVd with surcharge and (iv) dynamic

temping and (v) soft pocket identification, removal and

compacted backfilling. table 1 presents the comparison of cost

and completion time for different methods. Both time and cost

depends to some extent on the number of equipments mobilized

and source of material, particularly the surcharge (max. 5 m of

soil considered). considering the capacity of local contractors

minimal engagement of equipments and dredge sand from the

Karnaphuli river were considered.

though dynamic

temping/compaction appeared to be very prospective in terms of

time and cost, it posed the risk of damaging the adjacent yard

and structures. finally, pVd with surcharge was adopted as the

ground improvement measures, mainly because of reduced time

in pVd driving compared to sand drain installation, though

pVd is an imported material. also this method was considered

advantageous over other methods in bringing the clay layer to a

state where differential settlement potential will be reduced as it

will automatically take care of soft zones and bring the soft and

stiff zones to closer soil properties in terms of deformation and

strength.

since, from e~log(p) curves, most of the samples of the

upper clay layer was found to be normally consolidated, the

total consolidation settlement under the working loads (52 kpa)

without improvement was calculated using s

c

=

e.h,

e=c

c

/(1+e

0

)log(

p+p'

0

)/p'

0

and p'

0

=

'h where, e

0

= initial

void ratio, p'

0

= effective past maximum overburden pressure,

'=effective unit weight of soil, h=thickness of the compressible

layer. the estimated settlement for different borehole locations

varied from about 140 mm to 570 mm. this variation is due to

difference in e

0

, c

c

and layer thickness. in these estimations,

p

is calculated as

p =

0

[1-{1+(r/z)

2

}

-1.5

] where

0

=intensity of

stress applied on the surface, r = radius of the loaded area,

p=increase in stress at depth z from the centre of the loaded

area. this expression for

p is obtained by integration of

Boussinesque's equation that gives the stress at a point within a

semi-infinite, homogeneous, isotropic, weightless, elastic half-

space for a point load on the surface (Bowels,1988). estimated

time to achieve this consolidation (Uav

≈

99%) varied from

about 50 days to more than 700 days for different borehole

locations. the time was determined using terzaghi's one

dimensional consolidation theory with double drainage and

constant initial pore pressure distribution using the equations

(das, 1983):

m

0m

tm

2

av

v2

e

m

2

1 U

,

2h

tvc

vt

and

1 2m

2

π

m

it was intended to apply a surcharge with pVd such that a

maximum of 25 mm of total settlement remains to occur in

future under the working loads expecting a differential

settlement of not more than 12 mm. estimation of required time

to achieve this level of consolidation was made considering

both vertical and radial drainage (carillo,1942) as U=1-(1-

U

v

)(1-U

r

) where U

v

and U

r

are the average degree of

consolidation respectively for vertical and radial drainage. the

average degree of consolidation for radial drainage was

calculated using the following as

) 8 (

1

m

rT

r

e

U

where

2

e

vr

r

d

tC T

S

n

S n

k

k

n

S

S

n

S n

n m

s

h

ln

4 4

3

ln

2

2 2

2

2

2 2

2

w

e

d

d

n

and

w

s

d

d

S

the equivalent diameter of pVd was calculated following

hansbo (1979) as

)

(2

t b

d

w

where, b is the width and t is the thickness of pVd. considering

smear effect s was chosen between 1.0 and 1.2. the effective

diameter of soil column around the pVd was taken as d

e

=1.06s,

s=pVd spacing in triangular pattern.

for all the calculations horizontal permeability is taken as

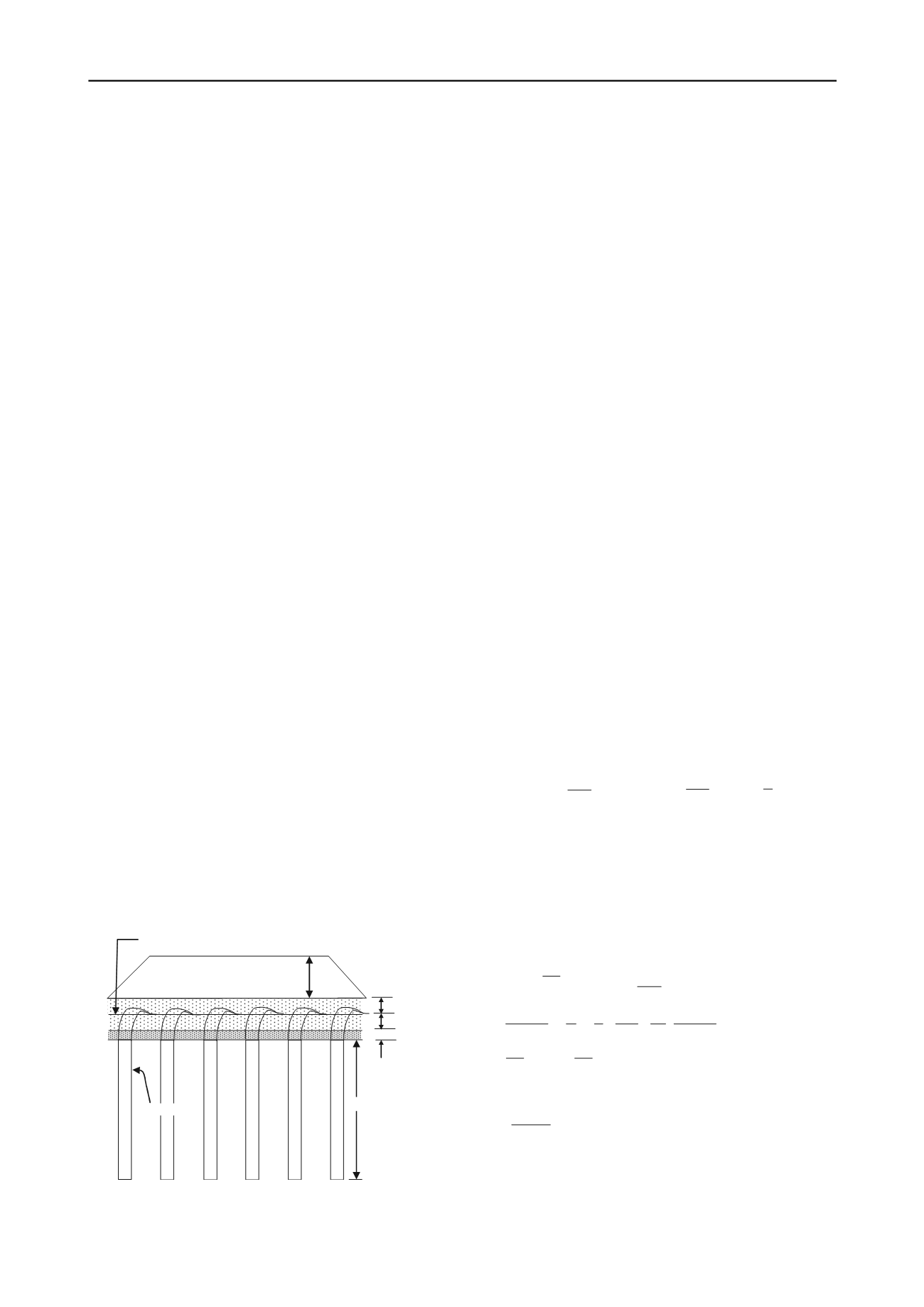

figure 4 details of the ground improvement work.

surcharge, 5m of soil

pVd

200 mm

5 m

Working surface for pVd installation

300 mm

150 mm