2420

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

3.4

Geosynthetic reinforced column or pile supported

embankment – the use of geogrids

Another way to use geosynthetic material for GI application is

the design of geogrids for the support of embankment, land

levees, yards and structure foundations (slabs and superficial

isolated or continuous footings).

Investigating the use of geosynthetics for reinforcement

under ground mass collapse,

Ponomaryov and Zolotozubov

(2013)

compare the method outlined in British Standard BS

8006 and several design approaches with numerical

calculations. On the basis of experimental elongation results,

they introduce the ratio of actual tensile force to deformation.

Computational assumptions are proposed for the description of

the mechanisms of stress-strain development in the reinforced

ground mass. The authors finally present a comparison between

experimental measurements and the results of seven different

methods used for the calculation of the tensile force in the

geosynthetic, its deflection and the surface settlement.

Mihova and Kolev (2013)

analyze the benefit of a

geosynthetic reinforced pad of crushed stone used for the

foundation of a hall in Sofia over soft saturated soil. Field tests

were performed to estimate the E-moduli before and after

improvement. The authors also conducted Finite Element

analysis to model the consolidation process and to confirm the

design stability under static and seismic conditions.

Dimitrievski et al. (2013)

present a history case of soil

reinforcement with geosynthetics for the construction of a six-

storey structure in Ohrid (Republic of Macedonia). Multi layers

geogrids were designed and the effects of the geostatic,

hydrostatic and dynamic loading conditions were studied with

the help of FEM calculations. The validity of the analysis was

demonstrated with the help of in situ measurements obtained for

a close similar structure.

3.5

Sand compaction piles (SCP’s)

In the sand compaction pile (SCP) method, sand is fed into the

ground through a casing pipe and is compacted by vibration,

dynamic or static compaction to form columns. In practice,

SCP’s are mainly used to prevent liquefaction and reduce

settlement with similar success in sandy and clayey soils. With

the help of laboratory and field tests,

Burlacu et al. (2013)

investigate the potential of columns made of loess-sand-

bentonite mixture for the reinforcement of collapsible loess

deposits in Romania. Indeed, as explained in the paper of

Alupoae et al. (2013)

, these collapsible soils require GI works.

They are characterized by high water sensitivity: when its water

content increases, important deformations in the soil can be

observed. In such a way to illustrate this phenomenon, the

authors present a case study of differential settlement of

buildings founded on loess sensitive to wetting. In spite of the

good realization and control of the foundation, important

differential settlements were measured thereafter as a result of

the defective rainwater recovery system.

3.6

Microbial methods

The use of microbially induced carbonate precipitation (MICP)

to cement cohesionless soils has recently received substantial

attention from geotechnical researchers. The most common

MICP mechanism is hydrolysis of urea. MICP via ureolytic

hydrolysis relies on microbes to generate urease enzyme, which

then serves as a catalyst for the calcium carbonate (CaCO

3

)

precipitation reaction. If it is to date well known that the

mechanical properties of the treated soils are directly correlated

to the amount of (CaCO

3

) precipitation, a gray area still remains

concerning the influence of the original nature of the granular

material on the resulting properties of the treated soil. Within

the framework of a laboratory campaign,

Tsukamoto et al.

(2013)

investigate the influence of the relative density of sand

samples on the MICP. As a result of their study, the MICP tends

to increase as the relative density of the soil decreases.

Nevertheless, considering the results of triaxial tests, maximum

principal stress differences were obtained for the samples with

the highest relative density. In light of these results, this

technique seems to be very promising for the future but due to

the bioplugging (permeability reduction) of the granular

material and to the generation of toxic product (ammonium

salt); soil stabilization using ureolytic MICP remains currently

unusual. According to

Hamdan et al. (2013)

, the use of plant

derived urease to induce the carbonate cementation could be the

solution to avoid these drawbacks.

4 GI WITH GROUTING TYPE ADMIXTURES

4.1

Deep Mixing Method (DMM) and soil stabilization

The deep mixing method (DMM) is nowadays a worldwide

accepted GI technology. In this method, the ground is in situ

mechanically (and possibly hydraulically or pneumatically)

mixed while a binder, based on cement or lime, is injected with

the help of a specially made machine. Numerous reviews and

recent progresses of the DMM are referred in Denies and

Van Lysebetten (2012). In the recent years, the DMM is

undergoing rapid development, particularly with regard to its

range of applicability, cost effectiveness and environmental

advantages, as illustrated by the papers of this paragraph.

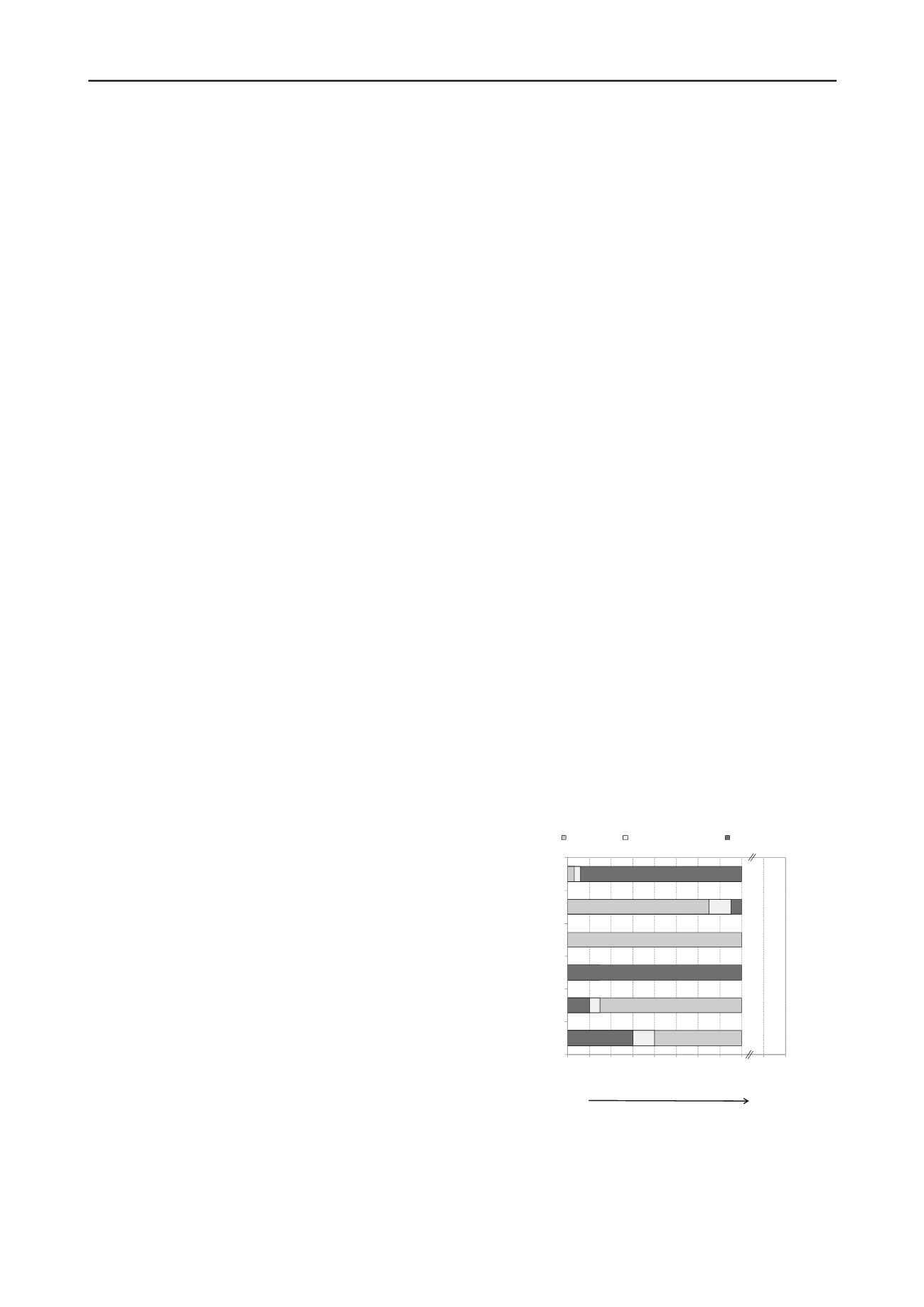

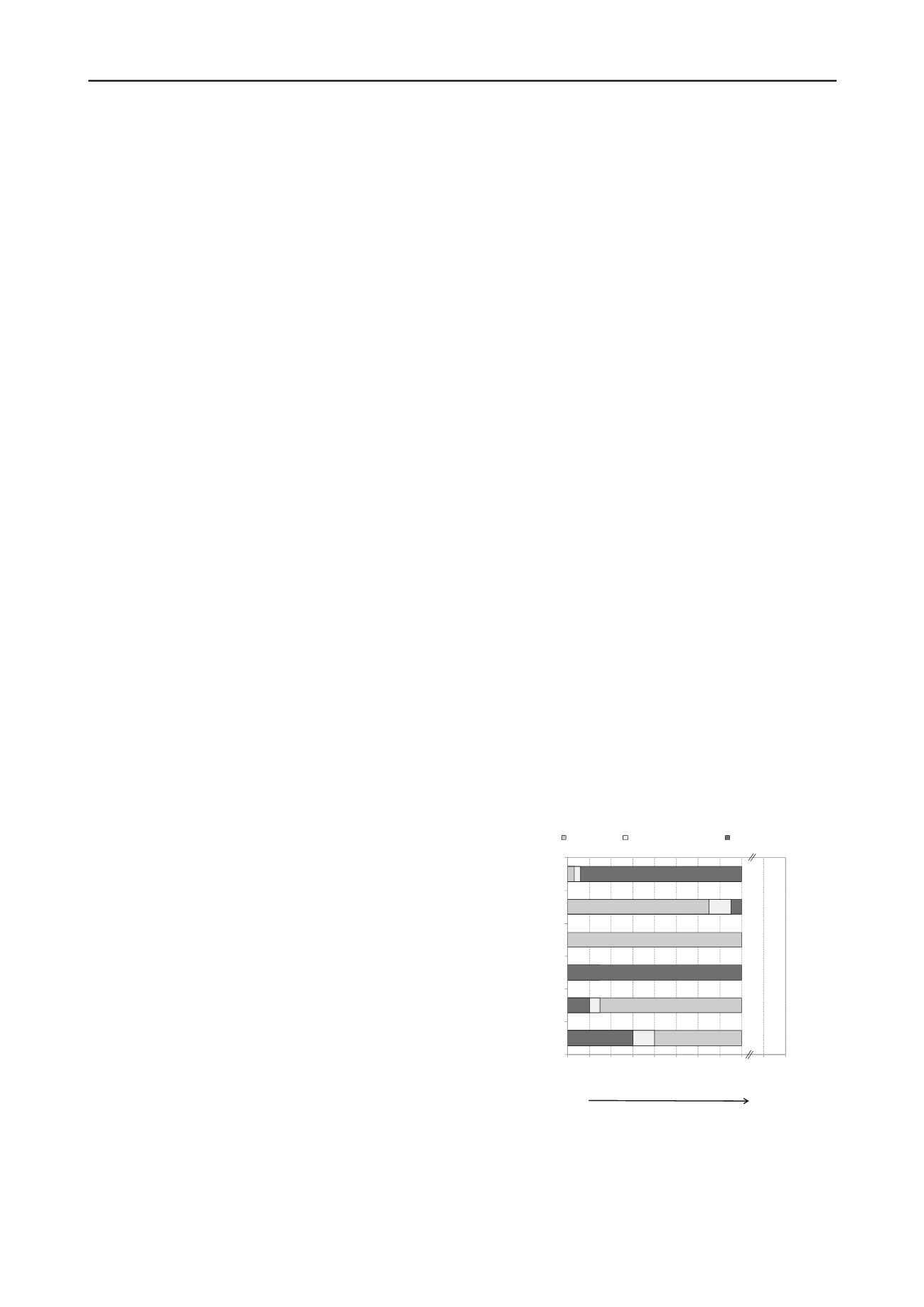

In the deep mixing projects, the design can be based on

laboratory mixing tests. Soil-cement samples are then prepared

and tested to study the mechanical properties of the stabilized

soil. But, up to now, many laboratories prepared these samples

without standardized procedure. Actually, molding techniques

have a great influence on the mechanical characteristics of the

stabilized material. According to

Grisolia et al. (2013)

, this

influence is strictly correlated to the workability of the soil-

cement mixture and this latter can be quantified with the

measurement of the torque required to turn an impeller in the

mixture. Five molding techniques have been studied and the

authors propose the abacus illustrated in Fig. 3 to define the

range of applicability of these techniques in function of this

torque.

0 10 20 30 40 50 60 70 80 90 100

mixture's workability, Torque

M

t

(Nm)

Molding technique

Applicable MarginallyApplicable NotApplicable

No Compaction

Tapping

Static

Compaction

50kPa

Dynamic

Compaction

Rodding

65 75

10 15

3 6

Static

Compaction

25kPa

30 40

High

workability,

liquid

Low

workability,

consistent

120 ...

Figure 3. Ranges of applicability of the different molding techniques,

from Grisolia et al. (2013)

The applicability of each molding technique was evaluated by

an “Applicability index”, related to “densest specimens with the

highest strength” and “results repetitiveness”.

Since several decades, DMM has been used for GI works.

But in recent years, this technique has been increasingly used