2422

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

semi-analytical model. Numerical results are in agreement with

the experimental observations all along the SLT but especially

regarding to the fracture pattern: structural failure localized in

the upper part of the column. This numerical study highlights

the nonlinear behavior of the soil-mix material. In comparison

with classical “rigid” piles, the contrast of strength (and

stiffness) between the column and the soil is lower and has a

huge influence on the global behavior.

Originally, DMM was developed for GI applications in soft

clays and organic soils. But more recently, it was also dedicated

to various structural and environmental applications such as

illustrated by the following case histories.

Recently, the DMM has been chosen for several Hungarian

railway projects involving soft soils, such as the restoration of

the “Sárrét” railway line crossing an area where the subsoil

consists of soft chalky silt. For the foundation of a 4m high

embankment, two DMM were taken into account: the mass

stabilization and the soil-cement columns.

Koch and

Szepeshási (2013)

firstly describe results of laboratory tests on

chalky silt samples mixed with cement for different w/c

contents. Both DMM are then assessed using 3D-FEM

considering the site requirements in term of stability and

settlement.

In a similar way, DMM have been widely used in Japan for

the improvement of soft clays and organic soils.

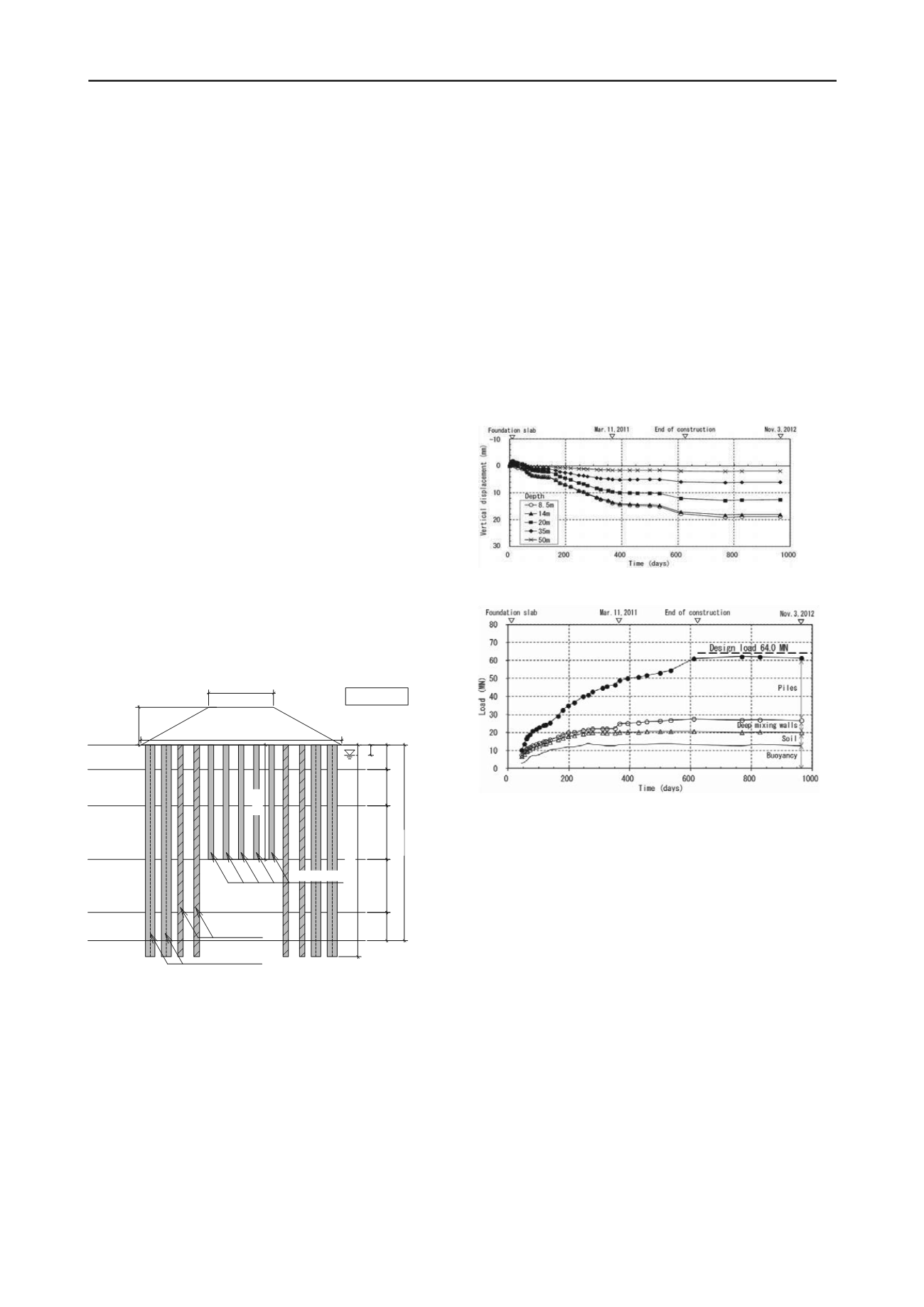

Matsui et al. (2013)

introduce the concepts of an hybrid

application of soil-cement columns combined with soil mix

walls (SMW) designed for the foundation of an embankment.

The concept is illustrated in Fig. 4. The authors propose a

conceptual method allowing the control of ground deformation

and ensuring an optimization of the volume of treated soil. The

method is supported by 2D-FEM and in situ monitoring is

performed for the validation of the concept.

Ac1- 2

As2

Ac2- 2

Dvc

Ac2- 3

12.0m

7.0m

37.2m

1:1.8

6.7m

10.0m

36.2m

1.9m

4.5m

Dvs

9.8m

5.2m

21.2m

39.2m

Inside piles

Outside piles

Walls

Section view

Figure 4. GI with soil-cement columns and SMW, from Matsui et al.

(2013)

In Lund (southern Sweden) a new generation synchrotron

radiation facility, called MAX IV, is under construction.

According to

Lindh and Rydén (2013)

, it should be 100 times

more efficient than any existing comparable synchrotron

radiation facility in the world. For this kind of facility, the

vibration requirements are very stringent. Various alternatives

were discussed and simulated during the conception. The

optimum solution was achieved with a four meter thick layer of

stabilized soil below the concrete foundation. A combination of

quicklime and ground granulated blast furnace slag (GGBFS)

was found to be in agreement with both design and construction

requirements.

Jeanty et al. (2013)

describe the use of the CSM and the

Trenchmix methods for the realization of SMW. Both

techniques are explained in details and different applications are

presented, namely: settlement reduction, improvement of slope

stability, reduction of active pressure on retaining walls and

decrease of liquefaction susceptibility. The two last topics are

then illustrated with case histories.

Other case history tackles the topic of liquefaction

susceptibility restrained with the DMM.

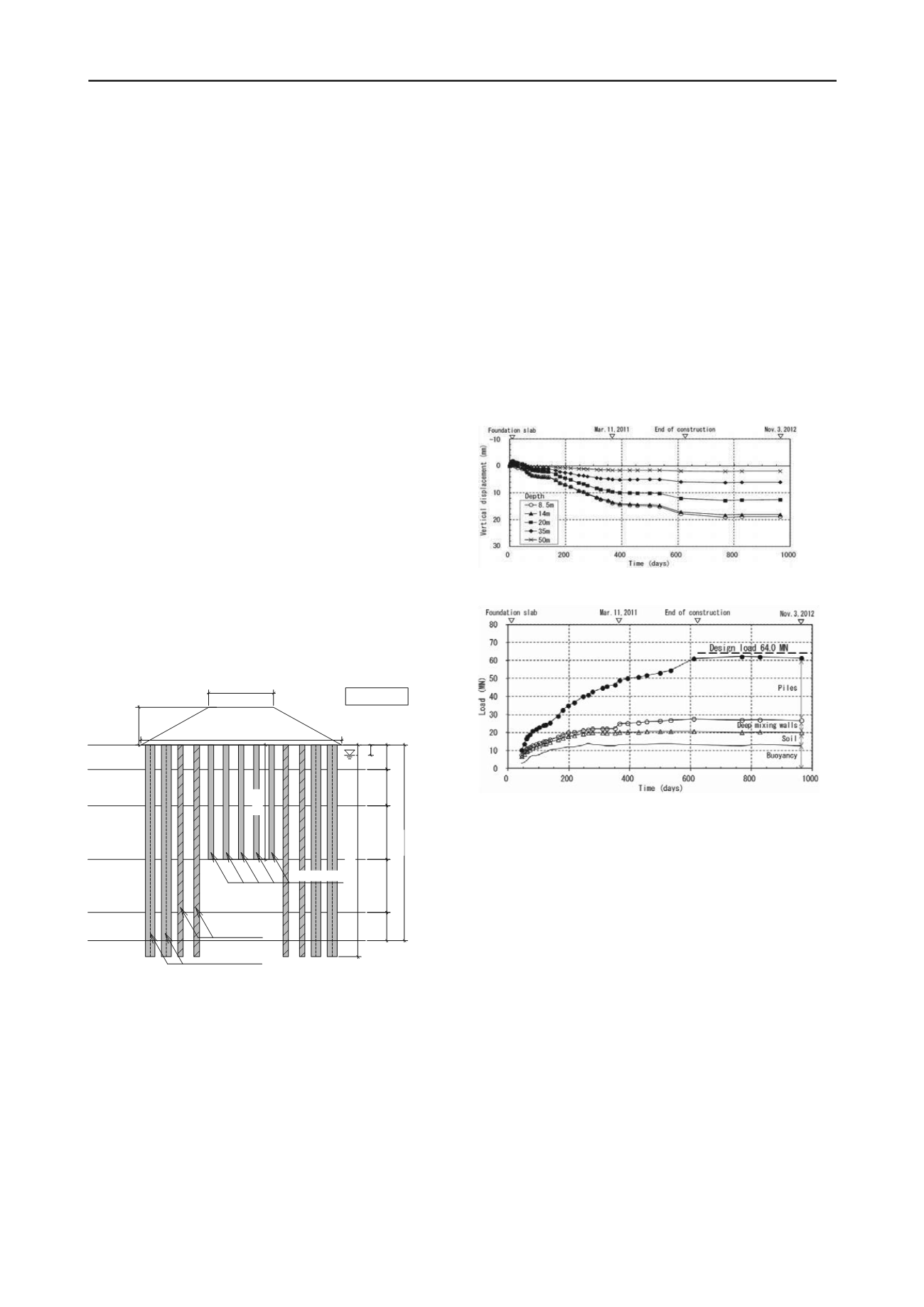

Yamashita et al.

(2013)

deal with the measurements performed underneath a

piled raft completed with SMW to reduce the risks of

liquefaction. It concerns a 12-storey office building. The load

distribution between piles, SMW and the surrounding soil has

been monitored during a period of three years. After the end of

the construction, settlements of 20 mm have been recorded, as

illustrated in Fig. 5. As another result, 70 % of the load was

taken by the piles, 14 % by the SMW and 15% by the soil, as

shown in Fig. 6. The measurements also learned that the

Tohoku earthquake of March 2011 had almost no influence on

the settlements and on the load distribution.

Figure 5. Measured vertical ground displacements below raft, from

Yamashita et al. (2013)

Figure 6. Time-dependent load sharing between raft and piles, from

Yamashita et al. (2013)

If the foundation of embankments and buildings are become

both common applications of the DMM, underpinning with soil

mix material constitutes an interesting emerging technique, such

as illustrated in the following paper.

Traditional DMM are commonly restricted for underpinning,

limitations being mainly related to the capacity of the machine

to pass existing foundation structures as reinforced slabs or

footings, the reduced working spaces and the possible low

headroom conditions.

Melentijevic et al. (2013)

present a case

history of underpinning of an existing floor slab in an industrial

building using DMM. The soil-cement columns were installed

with the new Springsol® tool. After the realization of a contact

grouting between the slab and the soil, the slab and the contact

grouting layer are cored. The spreadable Springsol® tool is then

introduced into the gap. Finally, its blades are opened and the

soil-cement column is executed until the predetermined depth.

The conception is supported by numerical modeling and

QA/QC aspects of the project are related to the testing of core

and wet grab samples.

4.2

Use of stabilized dredged material for construction

As previously discussed in Chu et al. (2009), dredging and land

reclamation have increasingly become important parts of

construction activities that involve heavily geotechnical

knowledge. If dredging provides low cost construction material,