2341

Technical Committee 209 /

Comité technique 209

The aforementioned patterns of behavior shown in Fig. 4 can

also be found in other tests with SLR of different values. The

accumulated displacement for each test fell qualitatively into

any of the three distinct patterns shown in Fig. 4:

(1) no accumulated displacement, as exhibited during the test

with CLR of 0.1;

(2) continuing displacement, as exhibited during the tests

with CLR ranging from 0.2 to 0.5;

(3) failure, as exhibited during the test with CLR of 0.6.

For the first case, the pile-soil system seems not to be

influenced by the cyclic loading and is in elastic range; only

small accumulated displacement was produced during the first

few cycles. For the second case, the pile-soil system was

influenced to some degree and partially entered plastic range;

the pile head showed continuing downward movement without

any apparent limit and the accumulation of displacement

depended on both of cyclic load level and number of load cycles,

and high cyclic load level and large number of cycles produced

larger permanent displacement. For the last case, the cyclic

loading had brought severe damage to the pile-soil system and

the pile fully entered the plastic range; the pile head moved

continuously downward at a rapid rate up to the end of the test

and a plunging failure might occur in some cases.

Thus, to divide the accumulated displacement responses for

the tests with a given SLR two critical values of CLR are

defined here, named minimum cyclic load ratio (MCLR) and

failure cyclic load ratio (FCLR), respectively. For CLR smaller

than the MCLR, the pile was in elastic range; for CLR greater

than the FCLR, the damage to the pile-soil system was severe

and the always caused “failure”.

The MCLR was found to be of 0.1 in all the tests and shown

to be unaffected by the SLR, and it can be inferred that if the

applied cyclic loads remained less than 10% of the ultimate pile

static capacity, the response of the pile can be considered to be

total elastic and the permanent displacement was negligible

after first several cycles.

The FCLR was found to be of 0.5 for the tests with SLR

ranging from 0.2 to 0.4. However, in the case of the test with

SLR of 0.1, the pile produced large permanent displacement

with CLR of 0.4, and it showed the tendency that lesser cyclic

loads were required to cause large permanent displacement for

the pile with very small SLR. Briaud and Felio (1986) reviewed

the previous cyclic load tests and concluded that a threshold of

peak load ratio (CLR+SLR) existed above which large

permanent displacement occurred and the value of that

threshold was about 0.8 on average. However, the tests results

suggest that the large permanent displacement depended more

on the magnitude of the cyclic load rather than the peak cyclic

load. It can be inferred from the results that large permanent

displacement occurred if the magnitude of the applied cyclic

load exceeds the 50% of the ultimate pile static capacity.

3.2 Prediction method

To investigate the evolution of the permanent displacement in

the tests in which the permanent displacement are identified as

“continuing displacement”, the results are replotted on double

logarithmic scales and the evolution of the permanent

displacement is evaluated in terms of the dimensionless ratio

0

( )

N

s

s

s N s s

s

s

(3)

which expresses the magnitude of the permanent displacement

( )

s N

caused by cyclic loading in terms of the displacement

s

s

that would occur in a static load test when the load is equivalent

to the maximum cyclic load (as defined by

(

)

u

SLR CLR P

).

The

0

s

and

N

s

refer to the permanent displacement in first and

N’

th cycle, respectively.

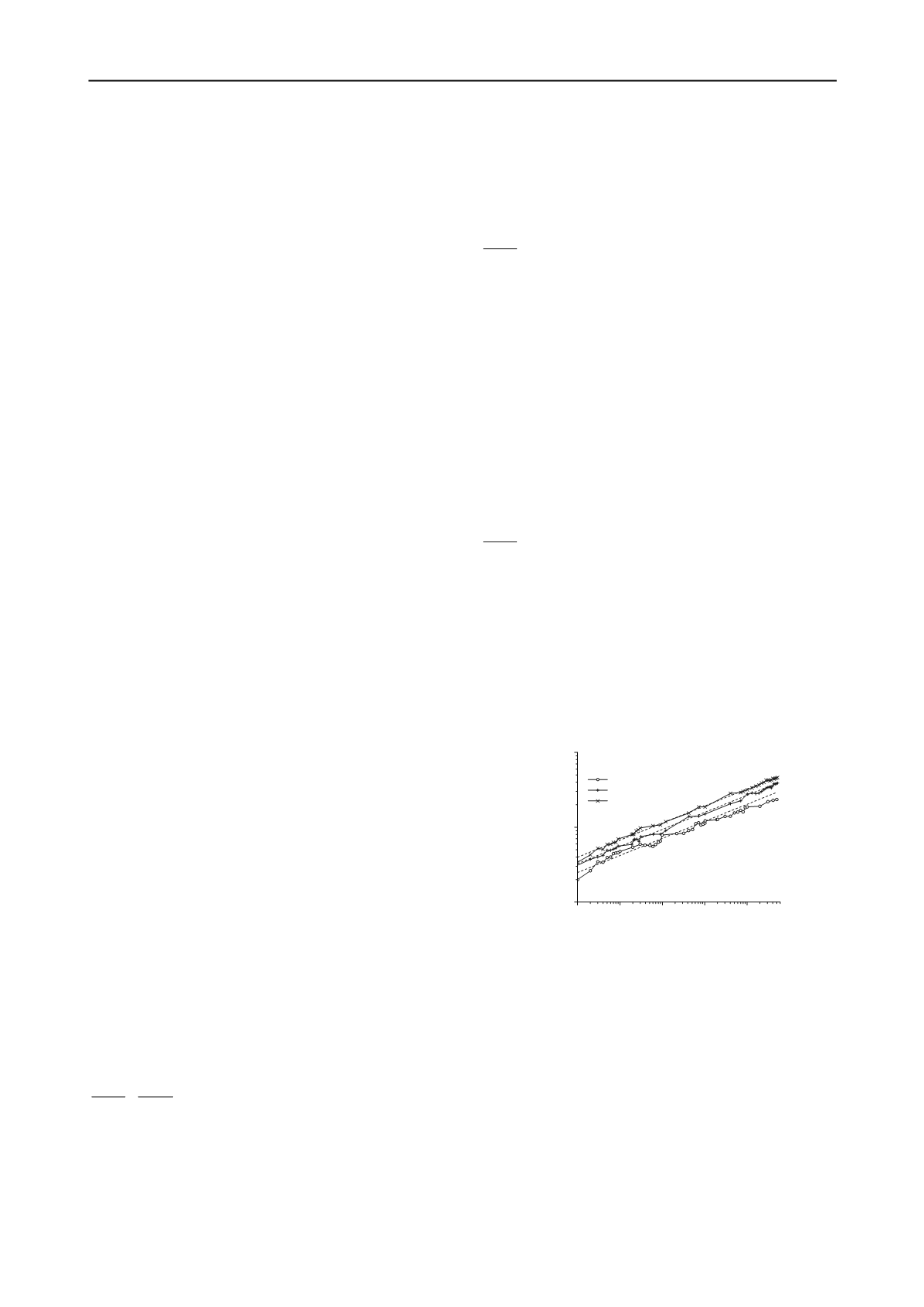

The results, plotted in Fig. 5, show that the trend in the data

follows the exponential behavior which appears as straight lines

in double logarithmic axes. This suggests that the permanent

displacement due to cyclic loading can be predicted by the

following power model:

( )

b

s

s N AN

s

(4)

where

A

and

b

are two parameters. It is observed in Fig. 5 that

all slopes are almost equal. This suggests that

b

is independent

of the load characteristics within the observed range. It is

introduced into (4) to represent the influence of load

characteristics on parameter in the following form:

(

1) (

)

m

n

A a SLR CLR

(5)

where

a

,

m

and

n

are three calibration parameters. Clearly,

when

0

CLR

, then

0

A

and no accumulated displacement

will occur under static load. Also, when

0

SLR

then

(

)

n

A a CLR

indicates that the accumulated displacement

depends only on CLR. Thus, substituting (5) into (4) gives the

following model for accumulated permanent displacement:

( ) (

1) (

)

m

n b

s

s N a SLR CLR N

s

(6)

The expression in Equation (6) was fitted to the data in Fig.

5 to empirically determine values of these parameters and back-

calculated parameters

a

,

m

,

n

and

b

for the tests are 0.054,

0.68, 1.24 and 0.23. The predicted results are shown by the

dotted lines in Fig. 5 and it appears that the influences of the

load characteristics on permanent displacement are reflected

well in the prediction. The closeness of the fit up to

4

5 10

cycles indicates that, in the absence of further experimental data,

it might be reasonable to extrapolate beyond

4

5 10

N

. Further

data are, of course, required to confirm this hypothesis.

10

0

10

1

10

2

10

3

10

4

0.01

0.1

1

SLR=0.3

s / s

s

N

Experimental:

CLR=0.2

CLR=0.3

CLR=0.4

Figure 5. Measured and predicted accumulated displacement

The dotted lines are obtained using Equation (6)

4 CYCLIC DEFORMATION DIAGRAM

Poulos (1988) proposed the idea of cyclic stability diagram to

investigate the capacity degradation caused by cyclic loading. In

this study, similar concept is used and the idea of a diagram

named cyclic deformation diagram is developed. The cyclic

defromation diagram for the model piles is shown in Fig. 6. In

the diagram, the aforementioned three types of displacement

response are represented by different symbols. Therefore, three

main regions can be identified on the diagram shown in Fig. 6:

(1) A stable (elastic) region I in which the cyclic loading

has no influence on the pile responses and the displacement

response is the type of “no accumulated displacement”.