2340

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Figure 1. The big soil tank at Zhejiang University

Table 1. Main soil properties

Property

Value

D

50

particle size (mm)

0.032

Specific gravity,

G

S

2.69

Plastic limit,

W

L

22.6

Liquid limit,

I

L

Plasticity index, PI

31.7

9.1

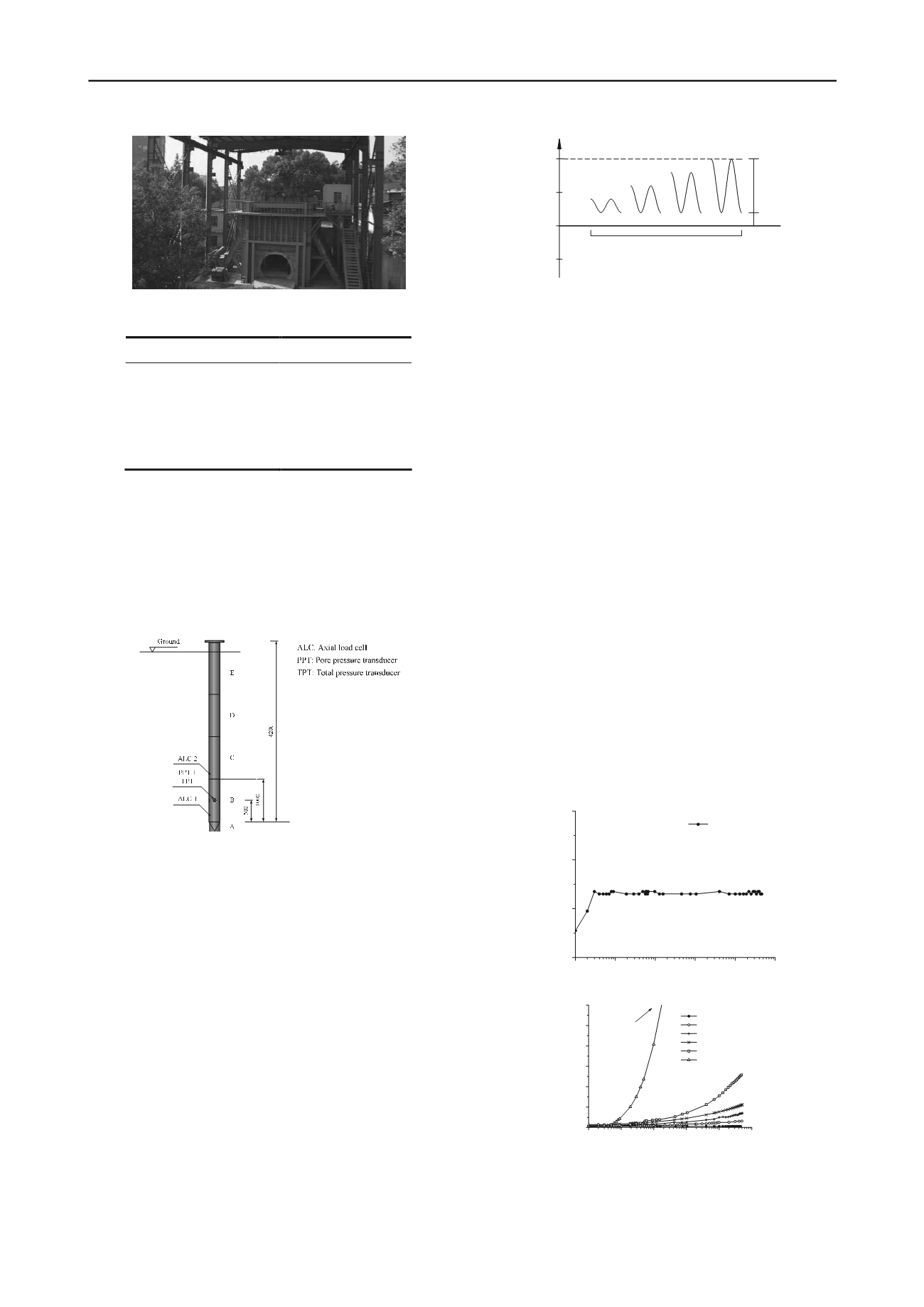

2.2 Model pile

The used instrumented model pile was closed-ended steel tube

pile with an outer diameter (

d

) of 168 mm, a wall thickness of 7

mm. The pile had a cone-shaped tip end with a cone angle of

60

o

. The model pile was designed to be assembled from four

segments to give a full length of 4.2 m. The instrumentation

consisted of axial load cells (ALC), total pressure transducers

(TPT) and pore pressure transducers (PPT).

Figure 2. Schematic diagram of the model pile (Unit: mm)

2.3 Characteristics of cyclic loading

The characteristics of the applied cyclic load are uniquely

defined using two independent parameters:

/

s

u

SLR P P

(1)

/

c u

CLR P P

(2)

in which

u

P

refers to the static ultimate capacity of the pile in

compression, and

s

P

is the minimum in a load cycle and

c

P

is

the cyclic load amplitude. In present study,

s

P

and

c

P

simulated

the self-weight from the superstructure and the cyclic load

induced by the high-speed trains, respectively. A visual

interpretation of the load ratios is given in Fig. 3.

P

U

P

CLR=

SLR=0.2

0.2

0.4

0.6

0.8

P

C

P

S

CLR=P

C

/P

U

SLR=P

S

/P

U

0

Figure 3. The characteristics of cyclic loading

In this study, the cyclic load frequency of 3Hz was used for

the tests and the sampling frequency was of 50 Hz.

3 TEST RESULTS

3.1 Accumulated settlement

The overall pattern of accumulated settlement of the pile with

SLR of 0.3 is presented in Fig. 4 by normalizing the

accumulated permanent displacement

s

by the pile diameter

d

.

The values of the CLR in this series ranged from 0.1 to 0.6. It

can be found that the ways in which displacement developed is

highly dependent on the amplitudes of cyclic load which can be

represented by the cyclic load ratio (CLR).

In the test with the smallest CLR of 0.1, extreme small

permanent displacement, of approximately 0.04%

d

was

produced in the first three cycles and remained nearly constant

from cycle No. 3 to 50,000. For the CLRs ranging from 0.2 to

0.5, the permanent accumulated displacement increased

gradually with the increasing number of cycles and also with

the increasing magnitude of cyclic load. For the tests with the

CLR of 0.2, 0.3, 0.4 and 0.5, the permanent displacements at the

end of the tests were 0.15%

d

, 0.35%

d

, 0.56%

d

and 1.26%

d

,

respectively. The permanent displacement increased rapidly at

initial stage and had the highest rate of displacement increase in

the first few cycles, and then it kept increasing continuously

with a decreased rate of displacement increase and seemed to

increase without a final and constant value. For the test with

very large cyclic load, such as CLR=0.6, the pile head moved

downward in a very “unstable” way marked by a quick plunging

during the test and the pile failed with a total accumulated

displacement of 10%d in 2,147 cycles.

10

0

10

1

10

2

10

3

10

4

10

5

0.00

0.02

0.04

0.06

s / d (%)

N

CLR=0.1

SLR=0.3

(a). CLR=0.1

10

0

10

1

10

2

10

3

10

4

10

5

0.0

0.5

1.0

1.5

2.0

2.5

3.0

s / d (%)

N

CLR=0.1

CLR=0.2

CLR=0.3

CLR=0.4

CLR=0.5

CLR=0.6

SLR=0.3

s=10%d after

2174 cycles

(b). CLR=0.1~0.6

Figure 4. Normalized permanent displacement (s/d) with number of

cycles (SLR=0.3)