1825

Technical Committee 205 /

Comité technique 205

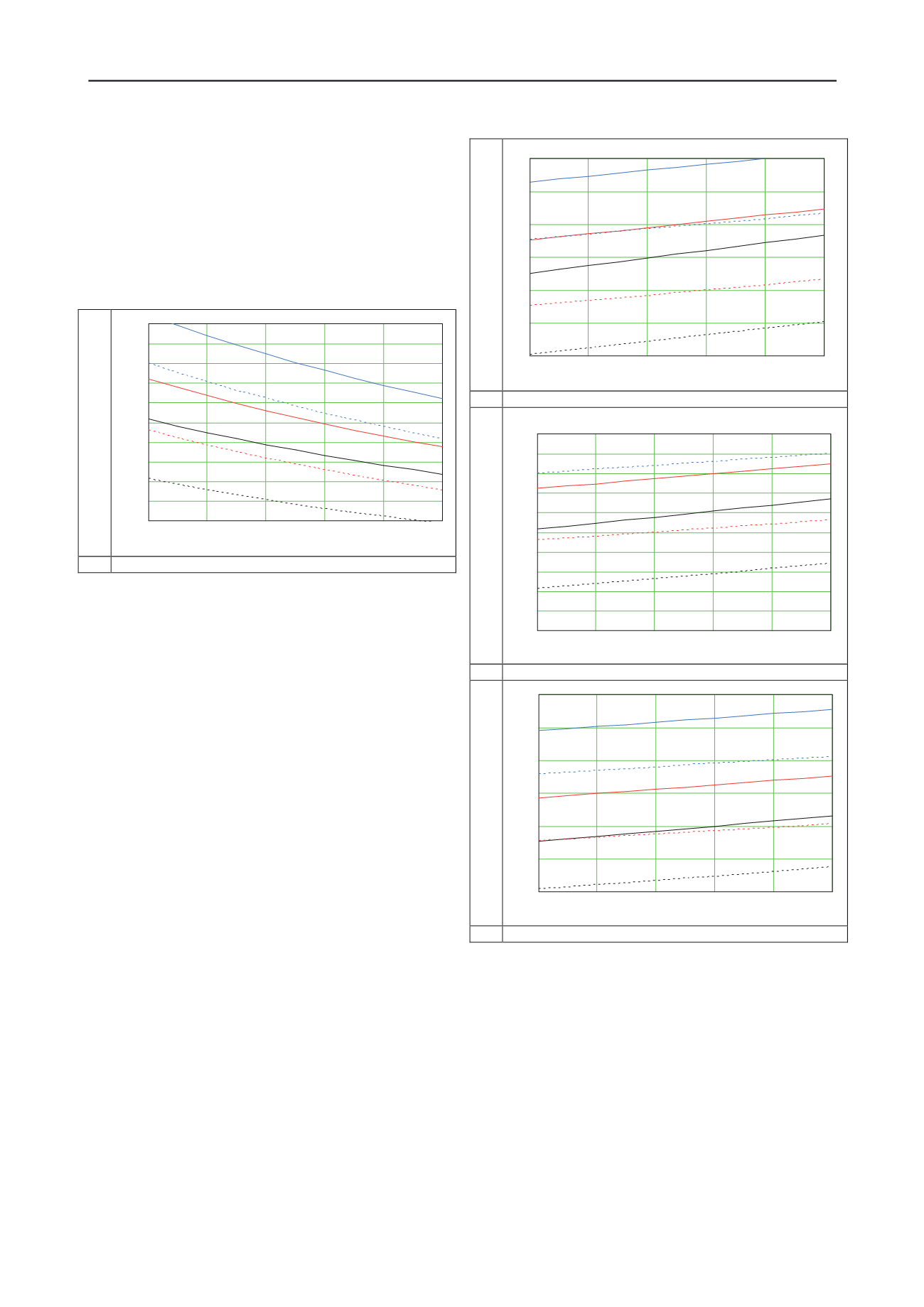

loads are

γ

G

= 1 and

γ

Q

= 1.3. The load distribution for both

permanent and variable loads is assumed to be normal. The

variable load distribution is set at 50-year loads and the target

reliability corresponds to RC2 of the Eurocodes, i.e.

β

50

= 3.8.

The calculations are done for material variation of

V

M

= 0.1,

V

M

= 0.2 and

V

M

= 0.3. In addition a general uncertainty

following a normal distribution and 0.1 deviation is added into a

parallel calculation. The results of the calculations are shown in

Figure 2 as the function of the load ratio (the proportion of the

variable load in the total load, %).

Material factor

γ

M

load proportion Q/(G+Q) [%]

Figure 2. Material factors of the Eurocodes corresponding to

γ

G

= 1,

γ

G

= 1.3 and

β

50

= 3.8 as function of load ratio. The lowest, black lines

denote to

V

M

= 0.1; read lines, middle to

V

M

= 0.2 and blue lines, highest

to

V

M

= 0.3. The dotted lines correspond to values without uncertainty,

V

U

= 0 and the solid lines with uncertainty,

V

U

= 0.1.

The results presented in Figure 1 are of course dependent on the

assumptions made. It is though notable, that the material factors

are not constant while they depend on the load ratio. For an

independent load combination the material factors would also

be highly non-linear. The application of a constant material

factor as in EN 1997-1 does not thus result in a constant

reliability index. Considering effective stress analysis, the

variation of the parameter is according to data gathered by

Abramson et al. (2002) in the range of 2-21%. On average one

could use the value of 10 % corresponding to the black line in

Figure 2. The recommended partial safety factor for friction in

EN 1997-1 is 1.25, which corresponds to a load ratio of 60% in

Figure 2. Stability problems are often less load driven while in

some cases the external load has no significant effect on safety.

For such cases DA3 would according to Figure 2 clearly

overestimate the safety.

3.4

Calculated material factors for alternative approach

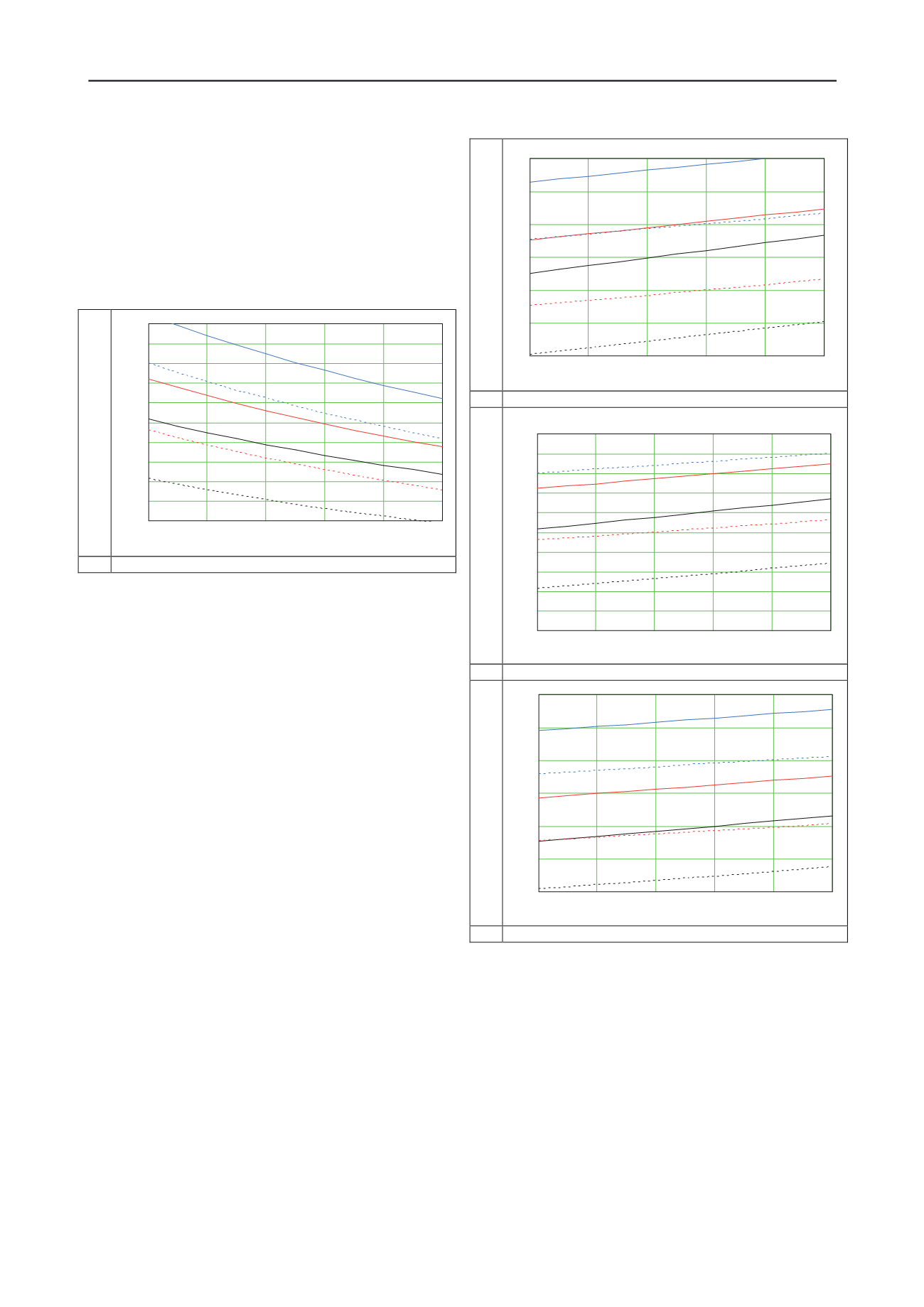

Next an alternative approach will be presented where all

uncertainty is placed on the material partial safety factor, i.e.

γ

G

=

γ

Q

= 1.0. In addition the material factors are calculated for

three different reliability index values, corresponding to the

three reliability classes in the Eurocodes. The target

β

values are

β

50

= 4.3 (RC3),

β

50

= 3.8 (RC2) and

β

50

= 3.2 (RC1).

Material factor

γ

M

a)

load proportion Q/(G+Q) [%]

Material factor

γ

M

b)

load proportion Q/(G+Q) [%]

Material factor

γ

M

c)

load proportion Q/(G+Q) [%]

Figure 3. Material factors corresponding to

γ

G

=

γ

Q

= 1.0 and a)

β

50

= 4.3

(RC3), b)

β

50

= 3.8 (RC2) and c)

β

50

= 3.2 (RC1) as function of load

ratio. The lowest, black lines denote to

V

M

= 0.1; read lines, middle to

V

M

= 0.2 and blue lines, highest to

V

M

= 0.3. The dotted lines correspond

to values without uncertainty,

V

U

= 0 and the solid lines with

uncertainty,

V

U

= 0.1.

As can be seen, the material safety factors are the same as in

Figure 2 for equal reliability index when the load proportion is

zero. When Figure 2 and Figure 3 b are compared we find out

that an equal design outcome is obtained when the safety is set

both in the action and in the resistance or in the resistance only

(e.g. load proportion 60 %,

V

M

= 0.1, Figure 2:

γ

M

= .1.53, i.e.

(0.4+0.6

.

1.3)

.

1.53 = 1.81 which is equal to the value of Figure 3

b).

0

20

40

60

80

100

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

2.1

2.2

ii

ii

ii

ii

ii

ii

0

20

40

60

80

100

1.3

1.4

1.5

1.6

1.7

1.8

1.9

0

20

40

60

80

100

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2

2.1

2.2

ii

ii

ii

ii

ii

ii

0

20

40

60

80

100

1.5

1.75

2

2.25

2.5

2.75

3