1816

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

Table 3. Comparison of forces in wall and deflection (BP30#)

Embed-

ment

(m)

Bending

Moment

(kN-m/m)

Shear

Force

(kN/m)

Deflection

(mm)

Traditional

Approach

(Geoguide 1)

25.26

10,320

1,269

184.8

C580

21.24

19,610

2,403

193.9

% Change

- 16%

+ 90%

+ 89%

+ 5%

# BP30 is a pile with the highest retaining height of 19.4m

Based on the table above, there is an average decrease of 3m

embedment by using C580 approach which is about 14%

reduction to the original proposed embedment. However, the

advantage of the reduction of embedment by using C580 results

in a substantial increase in structural forces. Thus, it would

require an increase of structural capacity by increasing the steel

ratio in these cases.

5 COST SAVING

Although, the bending moment and shear force of the cantilever

bored pile wall increased 90% in average as shown in Tables 2

and 3 above, the increase of the steel reinforcement percentage

is only from 1.32% to 1.78% mainly due to the use of 3 m

diameter bored pile with high bending capacity. The cost

comparison using the two appraches is presented in Table 4.

Table 4. Summary of cost difference

Average

pile length

(m)

Steel

percentage

(%)

Total cost per pile

(million HK$)

Traditional

Approach

(Geoguide 1)

43.0

1.32

3.03

C580

39.5

1.78

2.74

% Change

- 3.5

+ 0.46

- 0.29

(Saving of 10%)

The increase of the construction cost of the bored piles is not

directly proportional to the increase of pile depth. Normally, it

is an exponential increase with depth. Thus, the reduction of a

pile embedment results in a saving in the overall construction

cost. From the table above, there is about 10 % of overall cost

saving on the cantilever bored pile retaining wall system when

using C580 approach. This represents an amount of HK$ 9.6

million saving on this project.

Besides the cost saving, there is also a non-quantified saving

by using C580 approach such as the reduction of construction

risk for deeper pile, (Sze et al 2005).

6 PEFORMANCE AND MONITORING

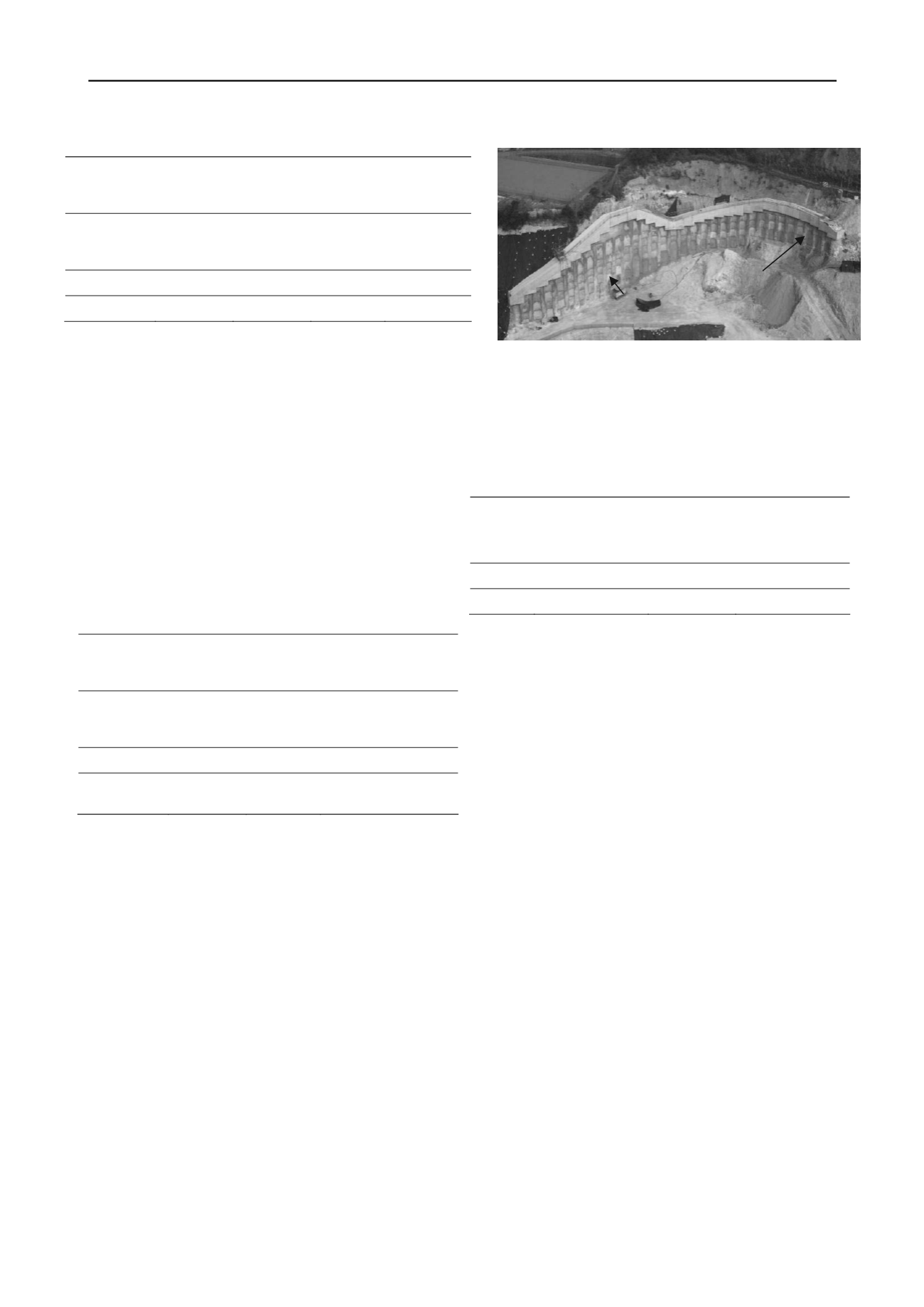

A 2.0 m deep capping beam was installed onto the pile heads

before excavation and deformation markers were provided for

the measurement of the wall top movement by land surveying

methods. The excavation commenced in December 2011 and

was completed by stages in June 2012, The condition of the

cantilever wall during the excavation stage in January 2012 is

shown in Figure 7.

SERVICE

RESERVOIR

ROAD

BP30

BP11

Figure 7: Excavation of the cantilever bored pile wall (January 2012)

The monitoring results of the wall top movement by land

survey is compared with the design predictions are shown in the

Table below. It is concluded that the use of C580 is a safe

approach for the design of a permanent cantilever bored pile

wall.

Table 5. Comparison of predicted and actual wall deflection

Traditional

Approach

(Predicted)

C580

(Predicted)

Actual lateral

movement

BP11

146.7 mm

146.7 mm

21 mm

BP30

184.9 mm

193.9 mm

20 mm

The actual movement from monitoring results maybe less

than predicted due to:

1. the beneficial effect from the capping beam is not

accounted for in the design

2. the slopping ground on the retaining side was

significantly reduced in height due to the formation of a

temporary piling platform and hence loading was reduced

3. local variations in the bedrock weathering profile was

not accounted for in the design

A comprehensive and continuous monitoring of the wall

movement was conducted throughout the construction period

comprising the followings will be discussed in future:

1. Piezometers provided behind the wall to monitor the

groundwater conditions.

2. Inclinometers and B-OTDR (Brillouin Optical Time

Domain Reflectometer) optical fibres were installed into ducts

reserved in the piles to monitor the behaviour of the cantilever

bored pile wall.

7 CONCLUSIONS

The use of C580 design approach together with partial factors as

suggested in “Notes on Design of Excavation and Lateral

Support Works Using the Limit State Partial Factor Method”

(BD 2005) is a safe and economic design for a cantilever bored

pile wall. In general, there is a cost saving by using C580

design in comparison with the traditional design approach as

described in Geoguide 1 (Second Edition)

However, the pile deflection profile and the long term effect

(i.e creep effect) of a cantilever bored pile wall system using

C580 design approach should be further reviewed.

8 ACKNOWLEDGEMENTS

Authors would like to thank Dr. P.L.R. Pang of Geotechnical

Engineering Office, HKSAR for the review and guidance of the

first C580 permanent cantilever wall design report.