1504

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

(Broms and Casparian 1965, Symes et al. 1984, Uthayakumar

and Vaid 1998, Sivathayalan and Vaid 2002). Therefore; the

more critical location may be away from the foundation

centerline, even though the major principal stress magnitude is

less compared to the one below the centerline.

Considering the inadequacy and also the inherent limitations

of CT (Cyclic Triaxial) and CSS (Cyclic Simple Shear) tests,

cyclic HC tests have gained more popularity for the

investigation of the effect of cyclic loads on the soil behavior

(Ishihara and Yamazaki 1983, Tatsuoka et al. 1984, Ishihara et

al. 1985, Tatsuoka et al. 1986, Koester 1992, Altun et al. 2005).

In this study the effect of changing in intermediate principal

stress ratio (b) on cyclic behavior and dynamic parameters of

Babolsar sand has been investigated. In all tests the direction of

the major principal stress was kept in vertical direction (α=0)

and intermediate principal stress ratio changed from a test to

another one to cover the range of variation of b value. For a

closer look of this trend, tests were conducted in two different

mean normal effective stresses.

2 EXPERIMENTAL APPARATUS

Advanced testing of geomaterials requires accurate control of

loads or deformations. Recent advances in the manufacturing of

testing equipment have eliminated the role of the operator in

modern systems. Most tests are conducted via closed loop

control mechanisms, which may involve servo hydraulic or

servo pneumatic systems. The closed-loop control system of the

dynamic HC apparatus used in this study has five main

components: (1) HC software, (2) high-speed data acquisition

system (DAS), (3) servo valves, (4) vertical and horizontal

actuators, and (5) load, pressure and displacement transducers.

The apparatus used in this study is made by Wykeham

Farrance International Company.

3 SAMPLE PREPARATION AND TESTS PROCEDUR

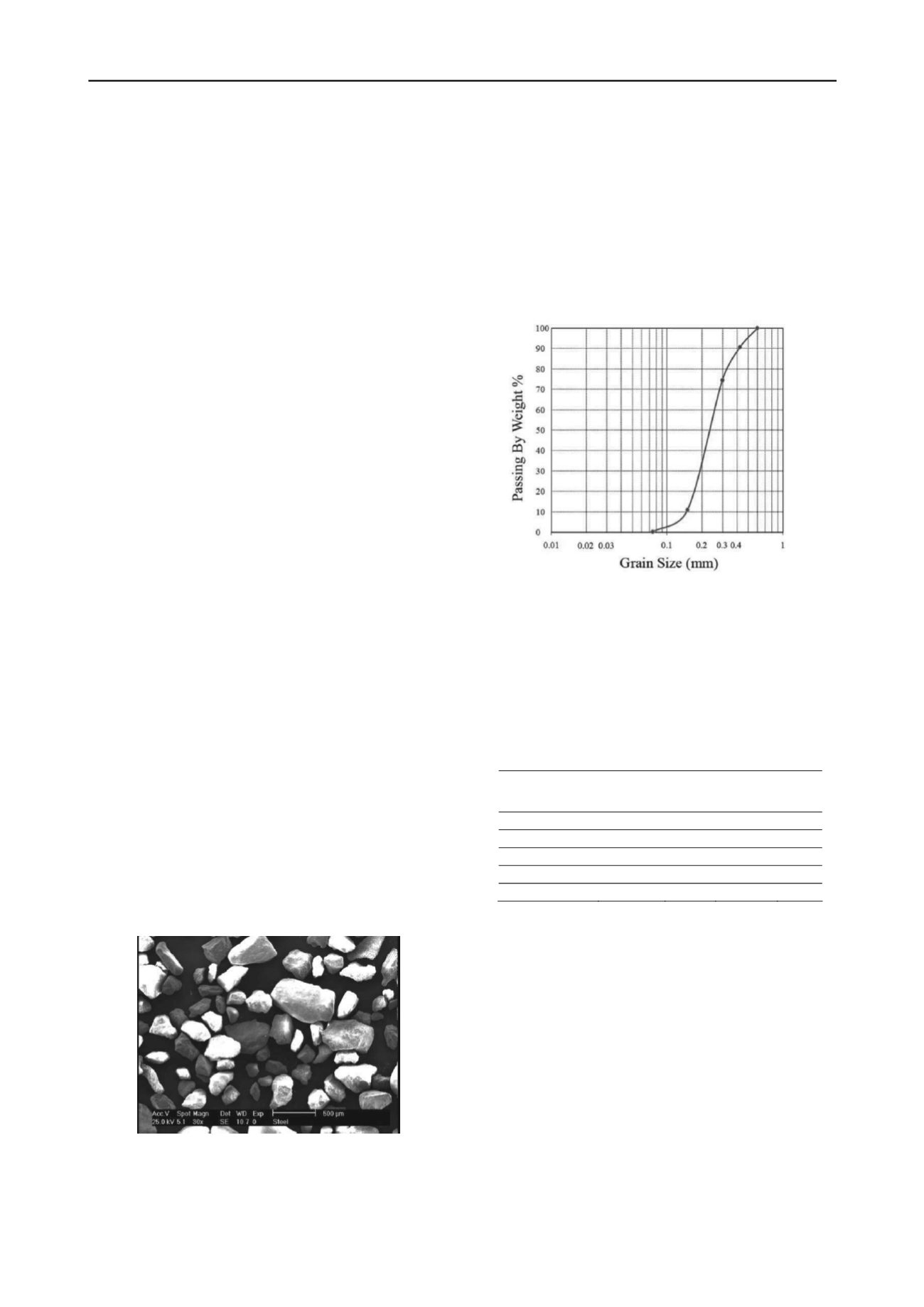

The original material used in this study was Babolsar sand

obtained from Caspian Sea coast in Babolsar, Iran. This uniform

sand was sieved to get the tested material, which has mean

particle diameter D

50

= 0.22

mm

, effective particle diameter D

10

= 0.14

mm

, a minimum void ratio e

min

= 0.543 and a maximum

void ratio e

max

= 0.820. The particles image is illustrated in

Figure 1. In this picture the grain size and shape of Babolsar

sand particles are evident. It is clear that particles are in the

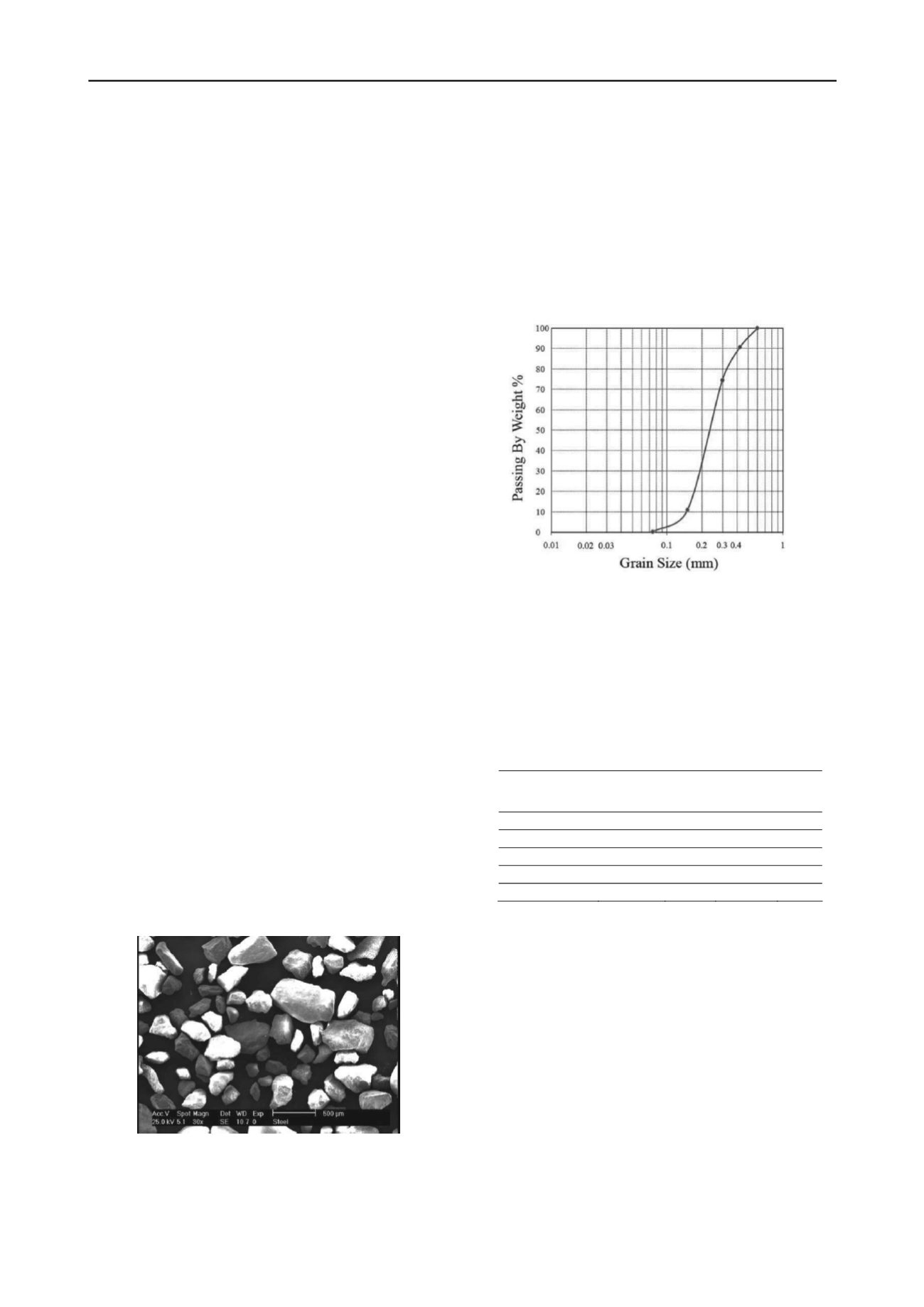

same size and partly angular. Grain size distribution of this sand

is shown in Figure 2. This sand classified as poorly graded sand,

SP; according to the Unified Soil Classification System. The

wet tamping method was used for preparation of the samples.

The samples were prepared to obtain relative densities in the

range of Dr = 22% ~ 25% after consolidation.

Figure 1. Particles image of Babolsar sand.

After construction of the samples, first CO

2

gas and then de-

aired water are passed through them. Next stage includes the

full saturation of the samples by applying inner, outer and back

pressure increments. This stage will continue to reach the B

value more than 0.94.

After that, the samples were isotropically consolidated to

reach 150 kPa mean normal effective stress.

Induced cyclic deviator stress was imposed under stress

controlled condition. In all tests the rate of induced cyclic

deviator stress to initial mean normal effective stress set as 0.27.

For keeping α and b constant during loading, the vertical

load and torque values were applied simultaneously as a cycle.

The purpose of this study is to investigate the effect of stress

anisotropy caused by changing in principal stress direction on

dynamic behavior of sand. 5 tests under controlled state of

principal stress direction were conducted.

Figure 2.Grain size distribution of Babolsar sand.

In these tests the inner and outer cell pressures were same,

therefore; the intermediate principal stress parameter is related

to the principal stress direction by Eq.1.

b = sin

2

(α) (1)

Detail information of the specimens and their loading details

for the mentioned tests are shown in Table 1.

Table 1. Detail information of the specimens

Specimens Id.

Dr(%)

σ'

0

(kPa)

α

(degree)

b

15010

83

150

10

0.03

15030

87

150

30

0.25

15045

84

150

45

0.5

15060

83

150

60

0.75

15080

86

150

80

0.97

4 TEST RESULTS AND DISCUSSIONS

The maximum shear stress in an element of hollow cylinder

samples is a resultant of two shear stresses. The first is a shear

stress arisen from torque (τ

zh

) and another is result of vertical

and horizontal stresses difference ((σ'

z

-σ'

h

)/2) or deviator stress.

The maximum deviator stress can be calculated from (σ'

1

-σ'

3

)/2.

As it was mentioned before, in these tests the samples are in the

same condition of fabrication and consolidation and the cyclic

load are imposed on the specimens under the controlled state of

the α and the rate of maximum deviator stress to mean normal

effective stress ((σ'

1

-σ'

3

)/2σ'

0

). Figure 3 shows these stress paths

of torsional shear stress and deviator stress. With regard to

Figure 3, during a test, the specimens are in triaxial compression

and triaxial extension state at α=10

o

and 80

o

loading condition,

respectively; and α=45

o

is associated by pure shear state.

Figure 4 shows the excess pore water pressure ratio (r

u

)

generation with shear deformation in tests with different α.

Results show that pore water pressure generation trend has

three phases. In the first phase, the pore water pressure