1493

Technical Committee 203 /

Comité technique 203

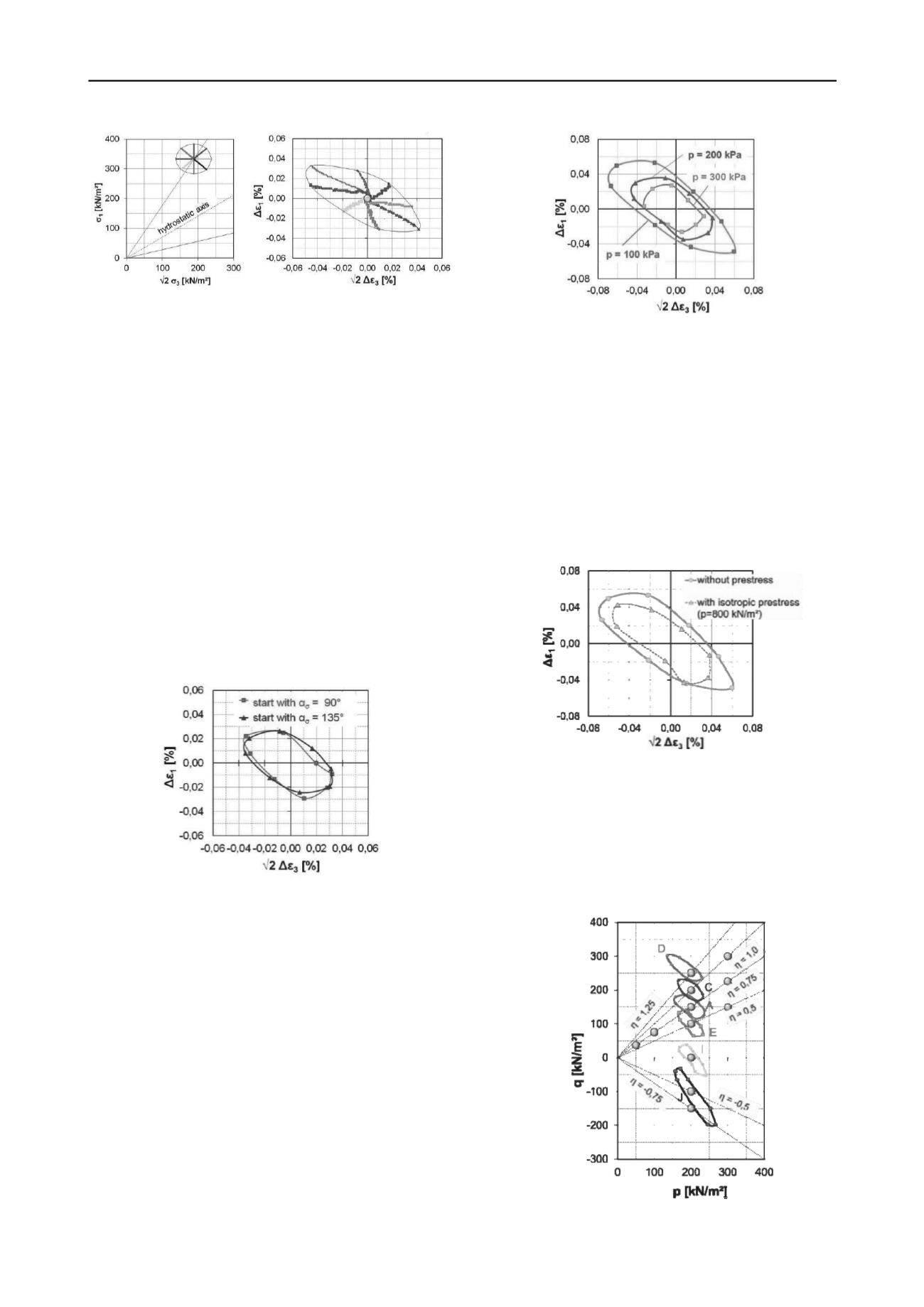

Figure 3: Construction of the strain response envelope

a) application of Δ

= 50 kN/m²

b) strain responses for

in 8 different directions

all 8 directions

The envelope of the strain-responses tends to have the shape

of an ellipse. The highest absolute values of quasi-elastic strains

always occur in the directions α

σ

= 135° and α

σ

= 315°; the

smallest absolute values result from directions α

σ

= 45° and

α

σ

= 225°.

The investigation of the influence of the sequence of the

directions, the mean pressure p, a monotonous isotropic

prestress and the stress-ration η on the shape, size and

inclination of the response-envelope, i.e. the direction-

dependent quasi-elastic stiffness, is described in the following.

3.3

Different sequence of stress paths

To investigate the influence of the sequence of the applied

stress-paths on the quasi-elastic strain-responses, the testing

procedure described in section 3.2 was applied for different

sequences of directions α

σ

. The rotational direction was also

varied and carried out clockwise and counter clockwise. It is

found, that – for the investigated initial stress-states – neither

the sequence nor the rotational direction of the applied stress-

paths leads to a substantial influence on the strain response

envelopes, figure 4.

Figure 4: Response envelopes due to Δ

= 50 kN/m² for 2 different

sequences of stress-paths from the same initial stress-state

Further test are carried out which seem to confirm these

results.

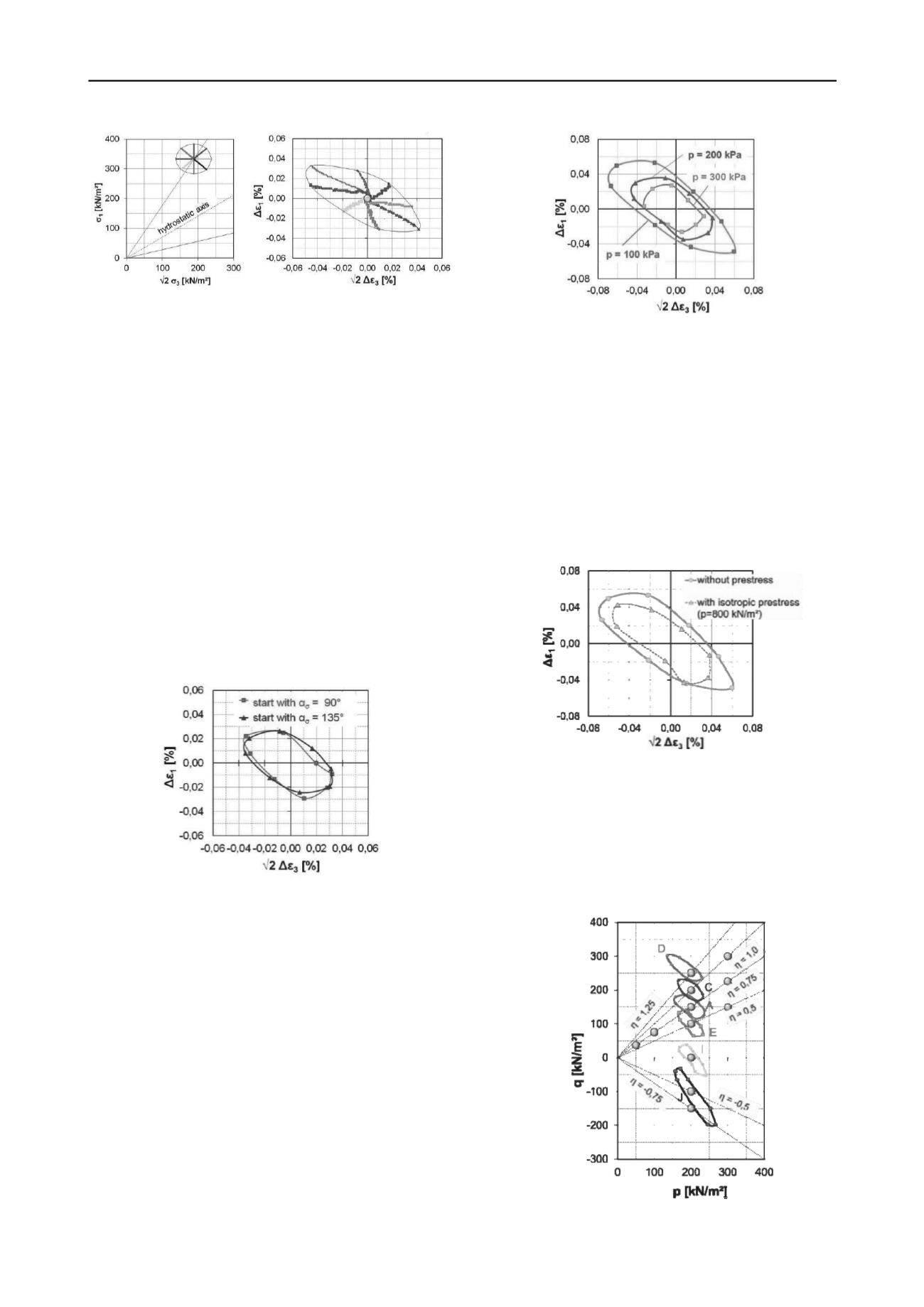

3.4

Stress-dependent stiffness

To investigate the stress-dependency of the quasi-elastic

stiffness at low cycle loading tests at 3 different initial stress-

states with a constant stress-ratio η and varying mean pressure p

were performed. The quasi-elastic strains due to a stress

increment Δ

= 50 kN/m² were determined and plotted by

means of response-envelopes, figure 5.

Figure 5: Comparison of response-envelopes due to Δ

= 50 kN/m² for

3 different mean pressures p and constant initial stress-ratio η = 0,75

As shown in figure 5 the size of the ellipses decreases with

increasing mean pressure p. This means that the stiffness

increases. This is especially evident at the stress-paths α

σ

= 135°

and α

σ

= 315°. The influence of p on the elastic moduli at the

directions α

σ

= 45° und α

σ

= 225° is much lower.

3.5

Isotropic prestress

To examine the influence of a static isotropic preloading on the

size and shape of the quasi-elastic response-envelopes, different

tests were carried out starting at the same stress point with and

without preloading.

It seems that the influence of an isotropic preloading is

negligible, figure 6.

Figure 6: Response-envelope due to Δ

= 50 kN/m² with and without

prestress

Similar observations were made when applying an

anisotropic preloading.

3.6

Anisotropy

To investigate anisotropic material properties, tests were carried

out for p = const. and different initial stress-ratios

. The

resulting envelopes are plotted in the p-q-plane, figure 7.

Figure 7: Rotation of axes of the response-envelopes depending on the

stress-ration