1488

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

different relative densities, as the relation was developed based

on the calibration chamber test data where soil conditions are

relatively homogeneous. In reality, it is not easy to measure

even PLR for routine piling work. For this reason, Lehane et al.

(2005) proposed a formula for estimating IFR

avg

, averaged over

20 pile diameters of penetration, as a function of the pile

internal diameter as follows:

0.2

min 1,( /1.5)

avg

i

IFR PLR

B

(3)

where

B

i

= pile inside diameters in meters. It should be noted

that the average of the IFR measured with the same penetration

increments over the entire pile length is equal to the PLR.

Yu and Yang (2012) determined that the ratio of unit end

bearing of soil plug to tip resistance from the cone penetrometer

tests (CPT) depends on PLR. They collected PLR data from

literature and suggested the following equation to estimate PLR

from internal pile diameter:

0.15

min 1,

i

PLR B

(4)

1.2

Pile design

The total axial capacity

Q

t

of open-ended steel pipe pile is the

sum of the limit skin friction

Q

s

and the ultimate end bearing

Q

b

:

t

s

b

si si

b b

Q Q Q q A q A

(5)

where

q

si

= limit unit skin friction for soil layer

i

;

q

b

= ultimate

unit end bearing;

A

si

= pile shaft area interfacing with soil layer

i

; and

A

b

= area of pile base. There exist many methods to

estimate

q

s

and

q

b

. Among others, the method proposed by

American Petroleum Institute (API) is one of the most widely

methods used for design of on- and off-shore foundations in

USA.

According to the API (2007), the unit skin friction in sandy

soils can be derived from the normal effective stress acting on

the pile shaft and the frictional properties between the pile and

soil interface as:

tan

s

v

q K

(6)

where

K

= coefficient of lateral earth pressure;

v

'

= vertical

effective stress in the center of the soil layer; and

= soil-pile

interface friction angle. The

K

and

are often incorporated

together as shaft friction factor

, and Eq. (6) then becomes:

s

v

q

(7)

According to the API (2007),

values vary between 0.37

and 0.56 for open-ended pipe piles driven in unplugged mode

for medium dense to very dense sands. The API suggests

increasing

by 25 percent for full-displacement piles such as

open-ended pipe piles driven in fully plugged mode or for

closed-ended pipe piles.

The unit end bearing for piles installed in sandy soils is

given as:

b q v

q N

(8)

where

v

'

= vertical effective stress at the base of pile;

N

q

= end

bearing factors ranging between 20 and 50, for medium dense to

very dense sands.

2 SITE CONDITIONS AND PILE DRIVING

2.1

General site conditions

The project area is about 270-m-wide and 400-m-long. A total

of 10 soil borings with Standard Penetration Tests (SPT) and 1

Cone Penetration Test (CPT) were performed within the area.

The existing site grade at the time of exploration varied from

about El. 354.5 m to about El. 359.5 m. At the time of pile

driving, the finished grade was at about El. 356 m, with typical

groundwater level at 6 m below the finished grade. The project

area generally consists of dense silty sands (typically consisting

of 60 % of sand, 33 % of fines, and 7% of gravel) from below

the finished grade to a depth of about 6 m. The SPT N-values

within this stratum generally ranged between 13 and 49 blows

with an average of about 31 blows. Below this layer, dense to

very dense sands (typically consisting of 89 % of sands and

11 % of fines) were encountered to a maximum depth of about

40 m. The SPT N-values within this stratum generally ranged

between 41 and greater than 50 blows. CPT also shows similar

soil conditions with average cone resistance

q

t

of 25 MPa to a

depth of about 6 m, and 42 MPa thereafter.

2.2

Pile driving and dynamic testing

A total of about 3,000 steel pipe piles were driven at the project

site. We measured plug lengths for about 1,355 piles. The pipe

piles driven in the project area consist of 406 mm x 9.5 mm

(pile outer diameter

B

o

x wall thickness

t

), 508 mm x 12.7 mm,

610 mm x 12.7 mm, 762 mm x 15.9 mm, and 914 mm x 19.1

mm open-ended steel pipe piles (corresponding to inner

diameters of 387, 483, 585, 730, and 876 mm, respectively).

APE D46-32 diesel hammer was used to drive the 406-, 508-,

and 610-mm-diameter piles. APE D62-42 and APE D80-42

diesel hammers were used to drive the 762- and 914-mm-

diameter piles, respectively.

We measured the hammer blow counts required for driving

piles each 0.25-m interval to the final penetration depths. After

completion of the pile driving, we measured the depth of the top

of soil plug using a wire-connected weight lowered inside the

pile and rested on top of soil plug. We then calculated the soil

plug length from the pile penetration depth and stick-up length

above the ground.

In order to estimate the pile capacity, dynamic load tests

were performed on 99 piles using the PDA. The pile capacities

were estimated based on signal matching analysis using

CAPWAP.

3 EXPERIMENTAL RESULTS

3.1

Soil plug length ratio

As mentioned earlier, we measured the plug lengths of a total of

1,355 piles. The pile penetration depths ranged between about

10 m and 30 m. The lengths of the soil plugs at various final

pile penetration depths are presented in Fig. 2(a) through 2(e).

The dashed lines in these figures represent the fully coring state,

and the solid line is a fitted line through the measured data. It is

clear that the solid lines become closer to the dashed line as the

pile diameter increases, indicating that the large diameter piles

were driven in close to fully coring mode.

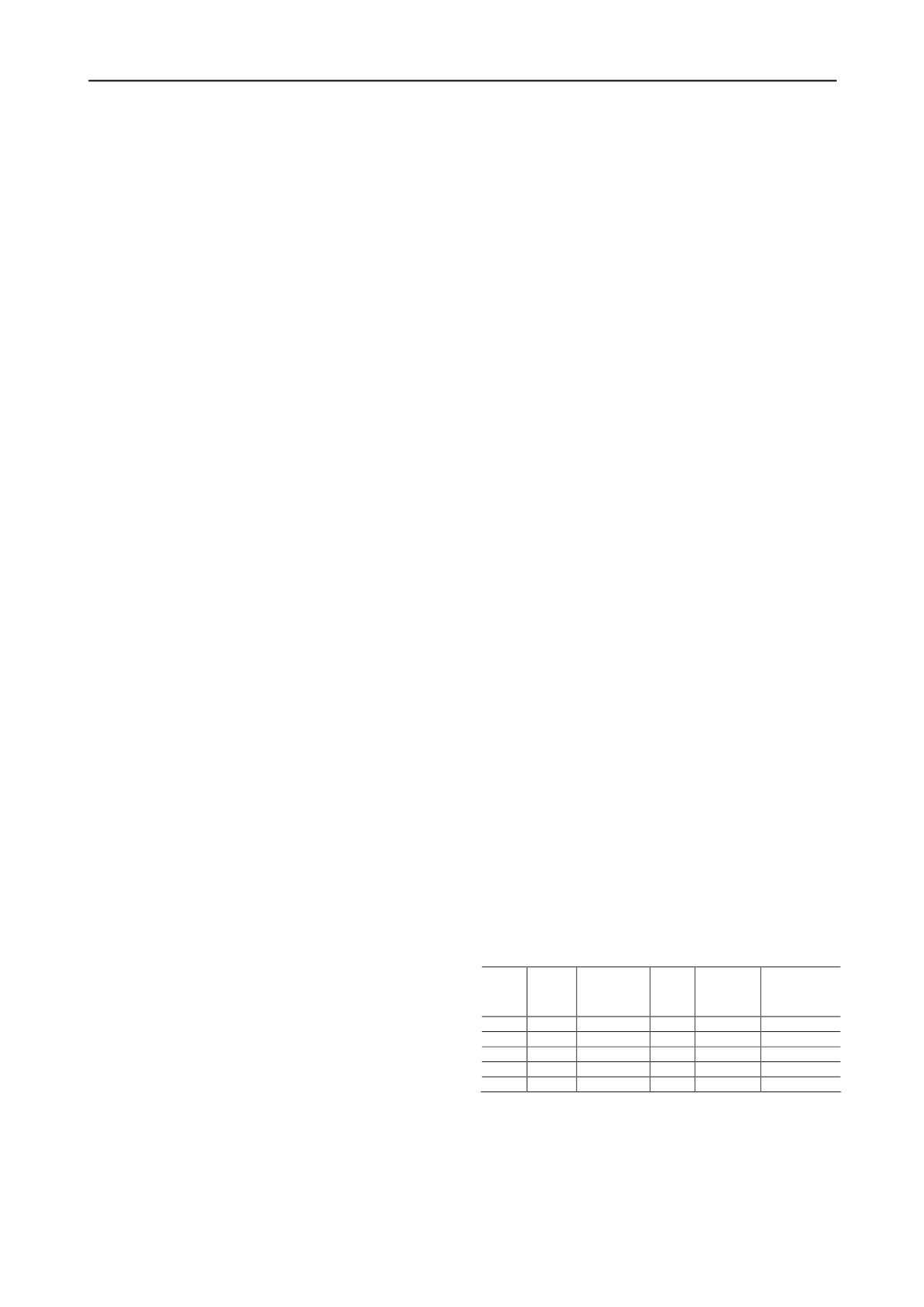

We performed histogram analysis of PLR values at final

penetration depths. A summary of the statistical data of PLR is

presented in Table 1.

Table 1. Summary of statistical data of PLR.

Outer

Dia.,

mm

Total

No. of

Piles

Penetration

Depth, m

Mean

PLR

Standard

Deviation

Most

Frequent

PLR Range

406

83 10.4 - 16.8 0.761 0.065

0.80 - 0.84

508 585 10.3 - 26.5 0.842 0.048

0.84 - 0.88

610 113 13.5 - 23 0.868 0.039

0.84 - 0.88

762 373 10.5 - 29.8 0.874 0.051

0.88 - 0.92

914 201 10.3 - 29.8 0.905 0.023

0.90 - 0.92

As seen in Table 1, the mean value of PLR increases from

0.76 for 406-mm-diameter pile to 0.91 for 914-mm-diameter

pile. Data from 406-mm-diameter piles show the most scatter

and 914-mm-diameter piles show the least scatter.