1492

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

compression as well as in extension region have to be

considered.

2

RESPONSE ENVELOPES

2.1

Concept

New or improved constitutive models need to be validated and

calibrated. This is often done with the aid of numerical element

tests, for example triaxial tests or oedometer tests.

So called response envelopes are a useful tool for calibrating,

validating and comparing constitutive equations (Sibille 2011,

Doanh 2000, Kolymbas 2000, Tamagnini 2006).

First basics of response-envelopes were presented in the

1970s by Lewin & Burland (1970). A few years later Gudehus

(1979) used this concept in context with the development of

constitutive equations.

To obtain a response-envelope, a soil element is subjected to

a certain stress- or strain-increment. The corresponding

“response” of the soil in form of either strain or stress is

determined and described graphically. The direction of the

implied stress- or strain increment with a constant absolute

value is then varied and leads to different stress- or strain

responses, endpoints of which are connected to a response-

envelope.

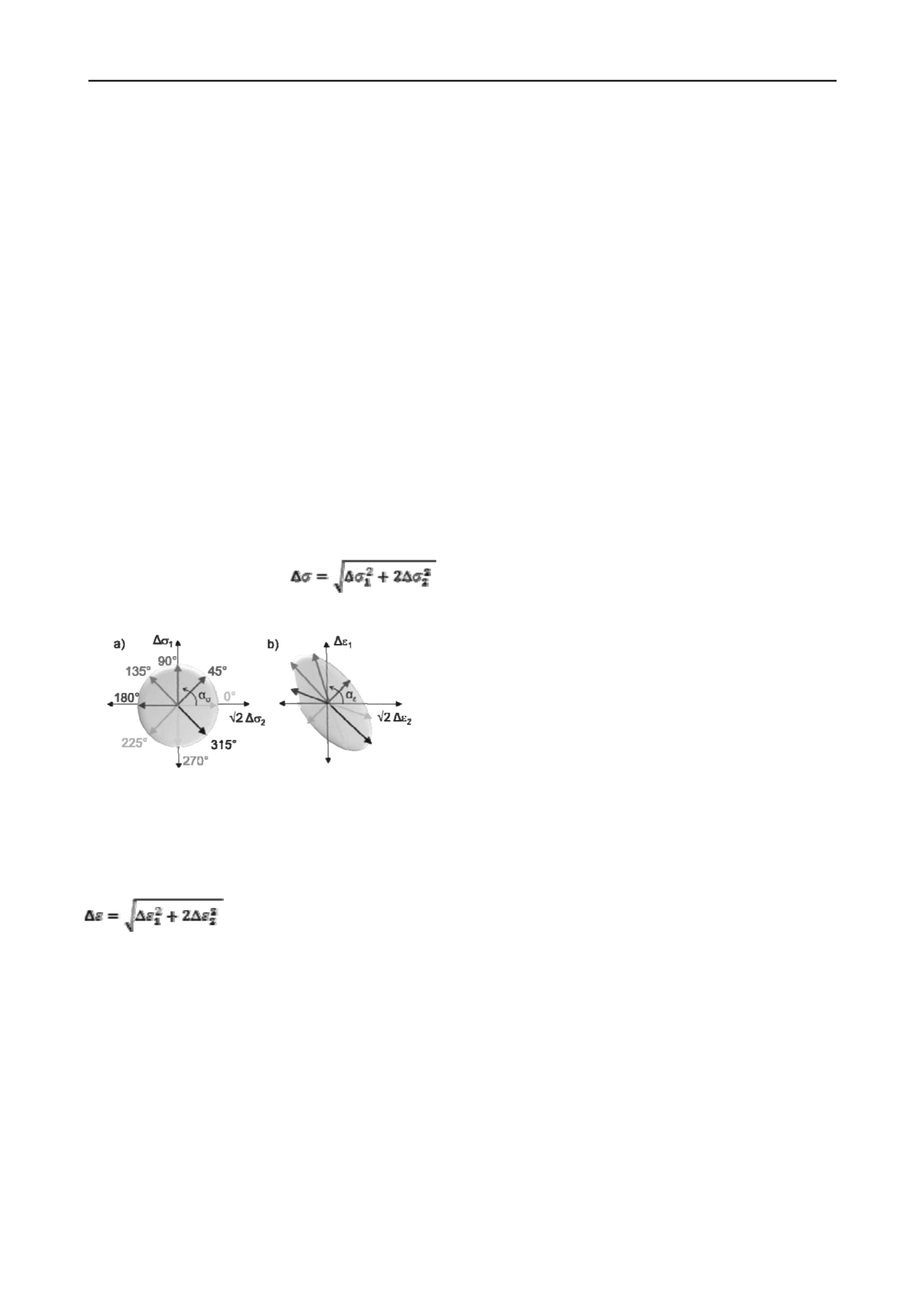

In figure 2 the strain-responses due to a constant stress

increment Δσ applied in 8 different directions α

σ

are shown.

Keeping the absolute value of

constant for all directions α

σ

, one gets a circle in the Rendulic-

plane with the axes √2

Δ

σ

2

and

Δ

σ

1

, figure 2a

Figure 2: Concept of strain response envelopes

a) applied stress increments

b) resulting strains

The α

σ

= 90°-stress-path in figure 2a for example is

equivalent to pure triaxial compression, in the same figure,

stress-path α

σ

= 180° stands for pure radial extension. The

strains are also plotted in the Rendulic-diagram (figure 2b),

where

the

resulting

strain-increment

is

.

The concept of response-envelopes is a convenient tool to

investigate the incremental stress-strain behaviour during first

loading as well as during un- and reloading-processes.

In this paper the quasi-elastic part of the strains, i.e. the

strains due to un- and reloading is investigated and evaluated by

means of strain-response-envelopes.

2.2

Literature

Only few experimental tests to obtain stress or strain response

envelopes can be found in literature.

Anandarajah et al. (1995) performed a series of stress-probe

experiments on dense and medium dense Ottawa sand to

investigate the dependence of magnitude and direction of

incremental plastic strain on direction of incremental stress. 6

different initial stress-states in compression were chosen and

stress increments from Δσ = 9 to 52 kPa in up to 10 different

directions were applied on triaxial specimens. The focus was set

on plastic strains, which were evaluated by subtracting the

elastic strains from the total strains. The elastic strains again

were either calculated “by using suitable elastic properties” or

determined by applying a stress cycle and measuring the elastic

strains during reversal.

Doanh (2000) for example describes tests producing strain-

response-envelopes at 3 different initial stress-states for dense

Hostun sand. The considered stress increment was

= 10 kN/m². For each direction, one soil-sample was used,

so that the determined strain increments can be interpreted as

total or elastoplastic strains after first loading. Quasi-elastic

strains were not determined separately.

Costanzo et al. (2006) performed several triaxial tests to

obtain strain-response-envelopes on a silty clay at 2 different

initial stress-states. The strains were investigated and plotted for

stress-increments between

= 20 to 90 kN/m². Quasi-elastic

strains were not considered explicitly either.

There is hardly any literature where “quasi-elastic” strain-

response-envelopes due to low cycle loading are presented.

There are quite some articles though, where quasi-elastic stress-

strain-behaviour is investigated after applying very small axial

or radial stress- or strain amplitudes (Ezaoui & Di Benedetto

2009, Hoque & Tatsuoka 1998, Kuwano et al. 2002).

3

RESULTS

3.1

Experimental fundamentals

The triaxial device used for the presented experiments is

equipped with high-resolution measurement- and control-

technology. The confining pressure as well as the axial force

can be controlled independently, so that any possible stress-path

from any initial stress-state can be followed. Height and

diameter of the soil specimen are 10 cm.

The tested soil is a fine grained sand with a low uniformity-

index (C

U

= 1,25 mm, d

50

= 0,15 mm). It could be shown by

different criterions (Nicholson et. al., 1993), that by using this

kind of sand, errors from bedding-effects and membrane-

penetration can be reduced significantly compared e.g. to

Karlsruhe middle-sand.

3.2

Testing procedure

Before running the triaxial tests the dry sand is pluviated to

obtain the soil sample and then the sample is saturated with

deaerated water. The specimen-preparation-method was kept

constant for all tests. The relative density varied between

I

D

= 0,6…0,7.

After saturating the soil sample, an initial stress state is

reached by first increasing the isotropic stress. Depending on

the position of the initial stress-state, either the vertical stress

(for stress-states in compression) or the horizontal stress (for

stress-states in extension) is then increased. Not only the mean

pressure p is varied, but also the deviator-stress q or the stress-

ratio η = q/p respectively.

Then stress cycles of relatively small stress increments of

Δ

≤ 50 kN/m² are applied in a certain direction α

σ

. To avoid

pore water pressure the frequency of the cycles is kept low.

The cyclic load in the first direction is repeated until the

measured strains are practically reversible or rather quasi-

elastic. The definition of “quasi-elasticity” implies that during

one cycle the plastic strains are less than 1…3 % of the total

strains, see Danne & Hettler (2011). It turns out that quasi-

elastic behaviour can occur after a low number of cycles. The

strain response of the last cycle is evaluated and plotted. After

that, the test is continued with the same stress increment Δ

, but

in a different direction α

σ

in the stress-space (figure 3a) until

quasi-elastic behaviour occurs again. The corresponding strains

of the last cycle are plotted in a diagram, figure 3b.