640

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

'

3

2 tan 0.1

'

'

z

c f

i

(7)

where, z is an arbitrary depth from the surface and

L is a

penetration depth from the bearing stratum (see Figure 6).

5 FULL-SCALE PILE LOAD TESTS AND THE

REDUCTION OF FACTOR OF SAFETY

In order to verify the applicability of the presented model and to

confirm the characteristics of the pile bearing capacity of each

layer, full scale pile load tests were conducted at two

representative sites, which locate at 12P and 22P sites shown in

Figure 3. As an important engineering judgment in this project,

the reduction of the factor of safety from 3.0 to 2.5 for pile

foundation design was discussed through comparing the

predicted results with the results of full scale pile load tests.

Figure 7 shows the soil profiles and N values with depth for

12P site. N-values can be seen to widely change with depth

from nearly zero to more than 20 and also N-values at pile tips

are roughly 30. The steel piles with a diameter of 1.0m were

carefully driven using vibration and hydraulic hummers. The

effective length of each pile was about 30m. Tests were

conducted based on the multi-cycles method, which is

recommended by the JGS (1993). Four strain gauges were

located at each of the cross sections as shown by the dots in

Figure 7.

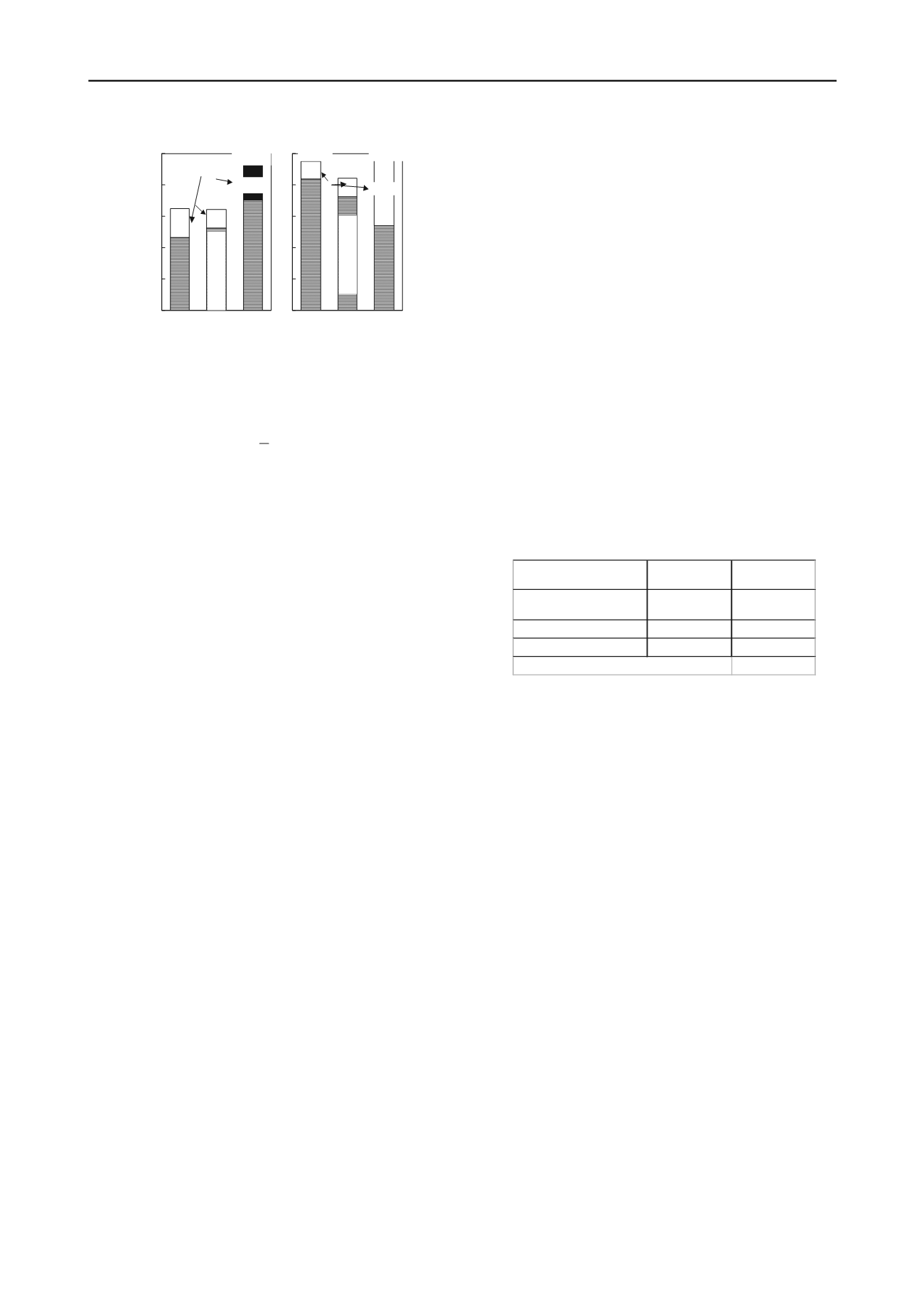

Figure 8 shows the comparison of the estimating total

vertical bearing capacities with those of full-scale pile load tests

at 12P and 22P sites, in which Eqs. (6) and (7) was used to

calculate the predicted values. The bearing capacity calculated

by the empirical model based on the measured N-values

recommended by JRA is also depicted in this figure. The model

used here can reasonably estimate both total skin friction and

pile tip resistance at both sites, comparing with those from JRA

recommendation. As shown in Table 1 and Figure 3, we have a

clear grasp of the soil characteristics values for each layer and a

practically efficient geotecnical profile. Therefore, the model

can apply very well to evaluate the pile bearing capacity

according to the ground profile at each site, with the

consequence that the accuracy of the prediction clearly

increased and these facts became an important evidence to

reduce the factor of safety for pile foundation design from 3.0 to

2.5.

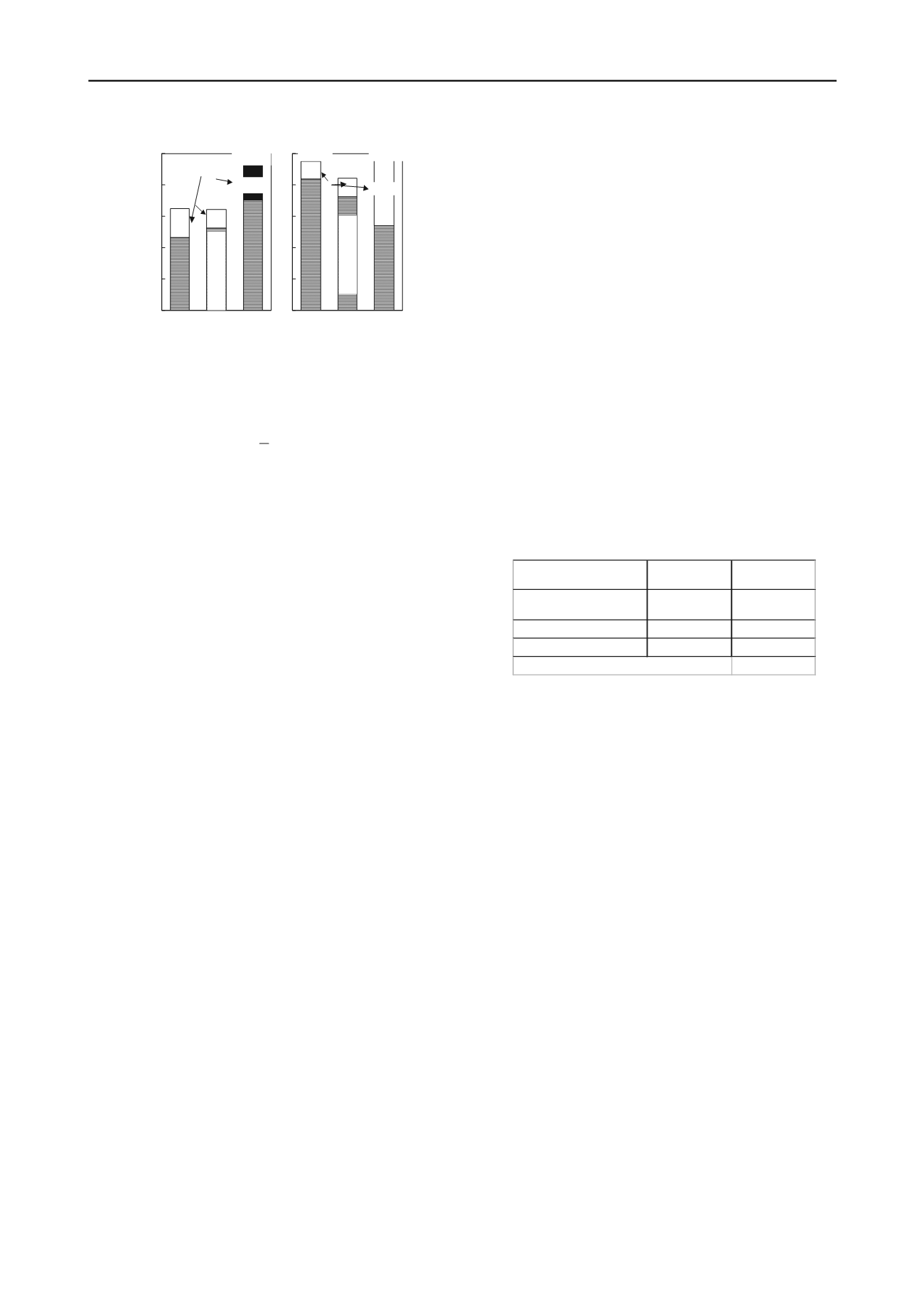

6 EFFECT OF A REDUCTION IN TOTAL COSTS

The comparison of the cost performance in terms of the

construction of pile foundations driven in P1 to P24 sites is

summarized in Table 2, which is a result of trial calculation.

Note that the cost is normalized by the cost obtained by the

standard manner for evaluating the pile bearing capacity using

N-values (JRA, 1993) without any full scale pile load tests. For

comparison, the layer of the bearing stratum for each case was

assumed to be same, however, the penetration depth

L was

considered to depend on the calculation manner. Total cost are

divided by 2 parts, in which one is the part for the cost related to

the geotechnical investigations which include in-situ and

laboratory soil tests, and full scale pile load tests, and the other

is related to the normalized total pile construction cost in terms

of P1 to P24 piers. The presented manner used here is expected

to cut the cost more than 15% comparing with the total cost by

the standard approach using N-values. Thus even if the cost of

the geotechnical investigations became roughly two times

higher comparing with the general manner, the appropriate in-

situ and laboratory investigation with a reasonable

considerations can reduce the total cost in the project. This is

due to the highly accurate ground profile and the proper

evaluation method of pile bearing capacity with the results of

the full scale pile load tests which reflected the decrease of

safety factor from 3.0 to 2.5. It is believed that the geotechnical

considerations and manner treated here can give an important

information for the geotechnical investigators, structural

designers and construction engineers.

(b) P22

Total skin friction

4.6MN

0

2

4

6

8

10

Measured

Values

Predicted

Values

N-Values

Total bearing capacity

9.5MN

8.4MN

Pile-tip resistance

10.0MN

(a) P12

Total skin friction

9.19

0

2

4

6

8

10

Measured

Values

Predicted

Values

N-Values

Total bearing capacity

6.5MN

16.2MN

Pile-tip resistance

6.4MN

9.2MN

Figure 8. Comparison of predicted total bearing capacities with

those of pile load tests

Table 2. Total cost benefit

Method by N-

values

Method

proposed here

Cost for geotechnical

investigations*

1

2.11

Construction cost for piles

1

0.82

Total cost

1

0.84

* the cost includes full scale load tests

7 CONCLUSIONS

An importance of integrating the geotechnical investigations

with pile foundation design was clarified through a case study

in terms of connecting bridge for New-Kitakyushu airport. The

following major conclusions were drawn:

1) A rational method for evaluating the pile bearing capacity

was presented which reflected the soil characteristic values and

geological environmental history. In addition, the applicability

of the presented method was confirmed through full-scale pile

load tests, with the consequence that the safety factors for pile

foundation design were reduced from 3.0 to 2.5.

2) In-situ and laboratory investigation with reasonable

geotechnical considerations can reduce the total cost of the

construction of the bridge for New-Kitakyushu airport.

8 REFERENCES

JSSMFE Standards for Vertical Load Tests of Piles. 1993.

Japanese

Geotechnical Society

, 113-121.

Japan Road Association. 1996. Specifications for Highway

Bridge Part IV, 330-337(in Japanese).

Mayne P.W. and Kulhawy F.H. 1982. K

0

-OCR relationships in soils,

J.

Geotech. Eng. Div., ASCE, 108(GT6)

, 851-872.

Ochiai H. and Yasufuku N. 2003. Investigation, design and construction

of the connecting bridge for New-Kitakyushu airport.

9

th

Annual

Meeting of Chinese Soil Mechanics and Geotechnical Engineering

,

1, 214-22