639

Technical Committee 102 /

Comité technique 102

considerations based on the results of the large numbers of in-

situ and laboratory tests. The resultant geotechnical engineering

map and the soil constants of each layers as characteristic values

are summarized in Figure 5 and Table 1, in which the soil

constants are mainly obtained by the standared consolidation

and triaxial undrained and drained compression tests. 3) Full-

scale pile load tests are conducted to confirm the validity of the

predicting method used for foundation design. The possibility of

reducing the safety factor for design to 2.5 from 3.0 is

considered through the geotechnical point of view based on the

field investigations, laboratory test results and the accuracy of

the predicting method with full scale pile load tests.

4 EVALUATION OF VERTICAL BEARING CAPACITY

OF DRIVEN PILES

4.1

Basic idea

Specification for Highway Bridge gives a following equation as

an estimating method of the ultimate pile bearing capacity based

on the results of the field and laboratory investigations (JRA,

1996):

Aq fLU R

d i i

u

(1)

Where R

u

: ultimate bearing capacity of pile, A: pile tip area, q

d

:

pile end bearing capacity, U: pile circumference, L

i

: thickness in

each layer, f

i

: maximum skin friction of pile. The first and

second terms are related to the skin friction of pile and pile-tip

bearing capacity, respectively. However, the main part of the

vertical bearing capacity of a pile is often mobilized from the

skin friction in practical designs within the limits of allowable

displacement, because relatively large displacements are needed

to mobilize the end bearing capacity. In addition, as a normal

open-end pile is used as a type of pile foundation, the end

bearing capacity strongly depends on the degree of the blockade

effect and thus the precise prediction of the end bearing capacity

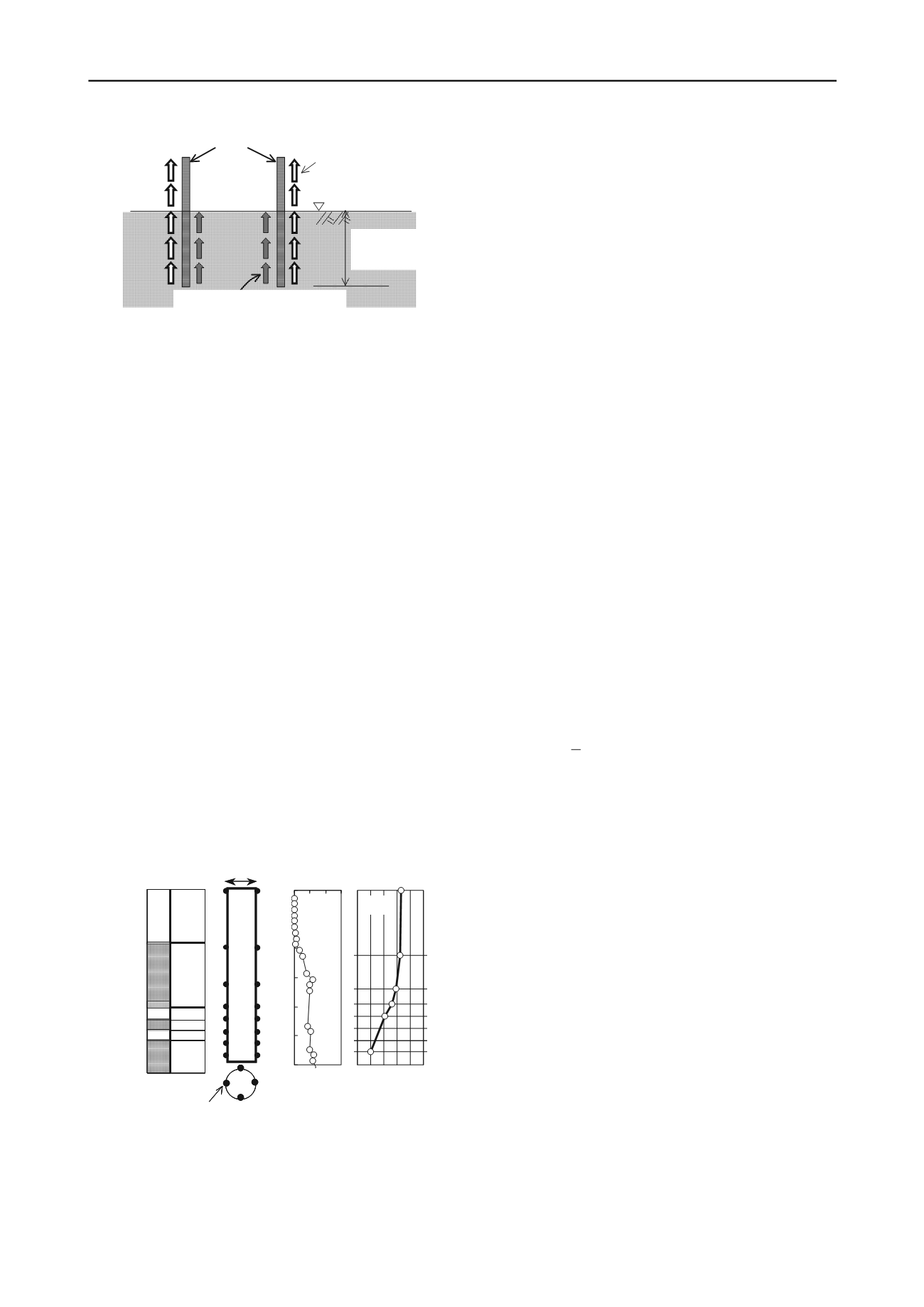

was considered to be quite difficult. Then, as shown in Figure 6,

the skin friction mobilized through the internal face of the pile

under the bearing stratum was assumed as the equivalent end

bearing capacity in the design. Therefore, the second term q

d

A

is expressed as U

Lf

i

.

Skin friction

mobilized

Steel pile with diameters of 1m

Bearing stratum

Penetration

depth

L

Skin Friction mobilized here

is assumed as pile-tip resistance

Figure 6. Basic idea of pile bearing capacity

4.2

Evaluation of skin friction

4.2.1

Basic equation

The following basic equation is therefore used for calculating

the skin friction of piles which is determined as the sum of pile

to soil adhesion and friction components:

'

'

'

tan

h

c f

(2)

c’

and

'

are the adhesion and friction parameters between pile

and soil, and

'

h

is the effective lateral stress acting on the pile.

4.2.2

Soil constants as characteristic values

An idea that the adhesion between pile and soils is roughly

equal to the apparent cohesion of soils c’ is widely used for a

practical design. It is mentioned that the applicability of this

idea is effective, irrespective of type of soils such as clay and

sand (e.g. Tomlinson 1980). Therefore, c’

in eq. (4) was

assumed to be equal to the apparent cohesion c’ of soils. In

practical design, the axial pile capacity is estimated for the

settlements of approximately 10% of the pile diameter. The

10% settlements usually exceed those for mobilizing the

maximum skin friction of pile. Further, when considering that

the mobilized mechanism of skin friction between pile and soils

surrounding the pile, it is reasonable to use the friction angles at

the critical state corresponding to sufficiently large

displacement

’

cv

as

’

(Yasufuku et al. 1997). Here

’

is

assumed to be conservatively two-third of

’.

’

is thus given

by

'

3

2 '

(3)

where,

’: effective friction angle at peak strength state.

4.2.3

Coefficient of lateral effective stress K

The mobilization of the skin friction is dependent on the lateral

effective stress

'

h

and thus in turn is dependent on the

overburden pressure

'

v

. When considering

'

h

is given by

, Eq.(2) is rewritten by

v

K

'

'

'

'

tan

v

K c f

(4)

K is a coefficient of lateral effective stress and

’

v

is vertical

effective stress. The coefficient of lateral effective stress K was

estimated from the previous research findings related to the K

0

-

value. K-values in Pleistocene clayey layers were determined by

the following equation (Mayne and Kulhawy, 1982).

'

sin

'

sin 1

OCR

K

(5)

where, OCR is over-consolidation ratio defined as the ratio of

the consolidation yield stress p

c

to the overburden pressure

'

v

.

Values of OCR,

’ in average and the calculated K-values in

Eq.(5) are measured against elevation. We can say that applying

this equation into the Pleistocene clayey layers, most of K-

values became more than 1.0. Based on the experimental

evidence, K-value for design was decided as 1.0, irrespective of

type of Pleistocene layers. Thus, the presented model for

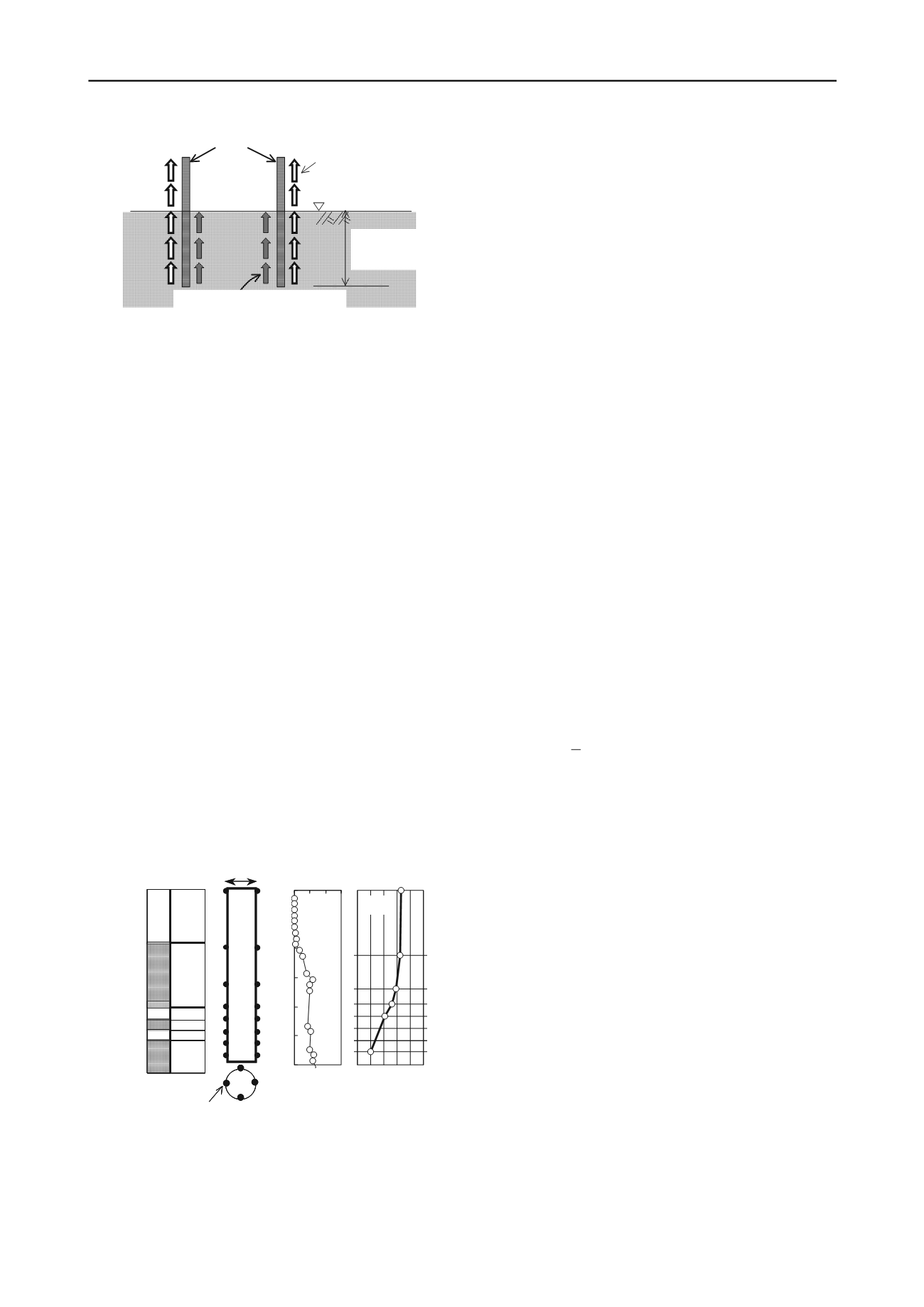

1.0m

Driven Pile (L=29m)

P12 site

DLs

DLs

Acl

(a)

Depth z (m)

0

5

10

15

20

25

30

DLc

DLc

DLs

Strain

gage (b)

S1

S2

S3

S4

S5

S6

S7

S8

0 2 4 6 8 10

Axial force

(MN)

(d)

0

5

10

15

20

25

30

0 20 40 60

N-Values

Depth (m)

(c)

(a)

Figure 7. Soil profile, N-values and measured axial force in pile

load test at P12 site

evaluating the vertical bearing capacity is expressed as

i

i i

u

Lf U fLU R

(6)