643

Technical Committee 102 /

Comité technique 102

once, otherwise they could not be regarded as representative

(Zabielska-Adamska 2006). The

CBR

tests were conducted on

unsaturated samples. All the samples subjected to penetration,

tested both methods – static and dynamic, and were loaded with

ASTM 1883-73 recommended load of 2.44 kPa. The static

(classic)

CBR

research was done on fly ash samples directly

after compaction. Higher

CBR

value was accepted as a result

D

50

(mm)

s

(g/cm

3

)

C

U

=

D

60

/

D

10

C

C

=

D

30

2

/

D

60

·

D

10

0.055–0.065

2.11±0.01

3.89–4.25

0.94–1.03

Modified Proctor method

Standard Proctor method

1opt

w

(%)

max1 d

(g/cm

3

)

opt2

w

(%)

max2 d

(g/cm

3

)

37.00

1.068

45.50

1.009

Table 1. Geotechnical parameters of tested fly ash shipment.

Tested fly ash parameters

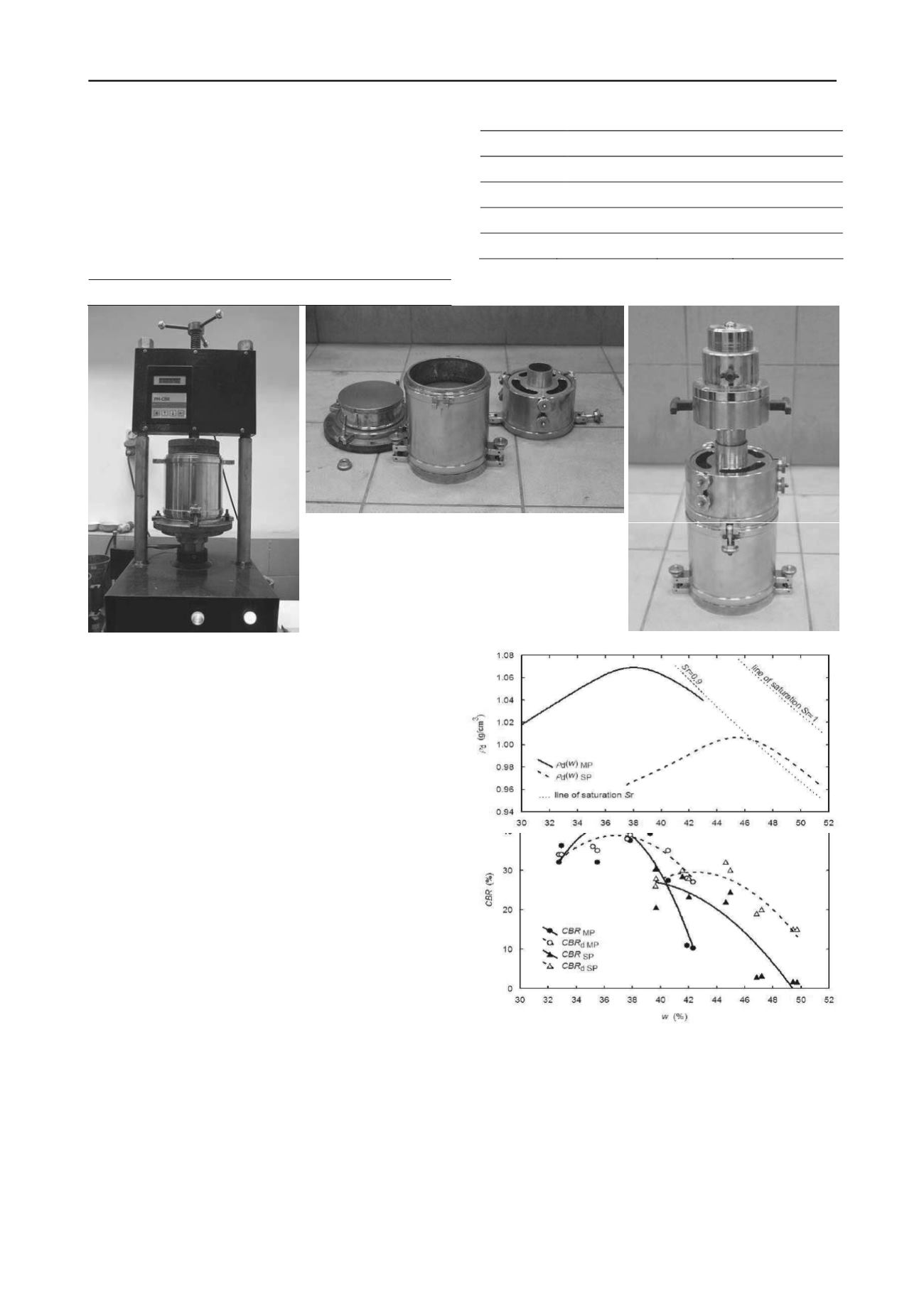

Figure 1.

CBR

research (from the left): static test;

changed mould basis and prepared mould extension for

dynamic

CBR

; specimen ready for dynamic test (photo

by Zabielska-Adamska).

calculated on the basis of pressing piston resistance, represented

in a given depth – 2.5 or 5.0 mm. Next, after levelling off the

surface of the same specimen and replacement of basis of the

mould, dynamic

CBR

was carried out. The

CBR

d

tests were

conducted using Light Weight Deflectometer (LWD) consisting

of a falling weight (7.07 kN) vertically movable along the guide

rod to produce a defined load pulse (3.6 MN/m

2

) of the

CBR

piston. Electronic measurement system gauged the depth of the

piston’s penetration in the tested soil after a single impact.

CBR

tests are shown in Figure 1.

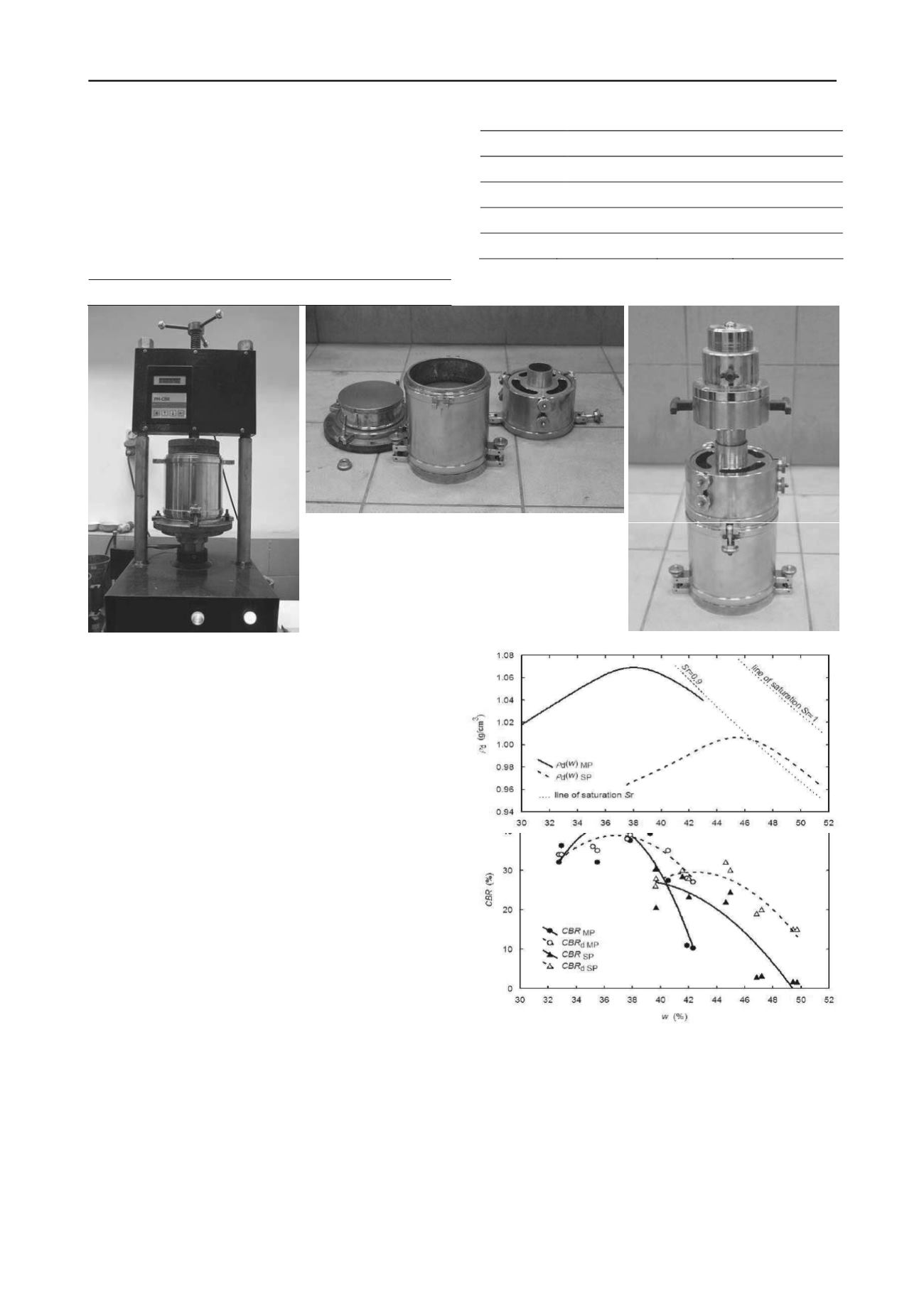

Figure 2 represents the results of standard and dynamic

CBR

testing, depending on moisture content at compaction, in

relation to compaction curves of fly ash, obtained by means of

two Proctor methods. Static

CBR

results confirm earlier results

obtained by the author.

CBR

of unsaturated samples of fly ash

reaches the highest values in the case of samples compacted at

the moisture content lower than optimum. The samples

compacted above optimum water content have still lower

CBR

values simultaneously with an increase of moisture content.

These relationships can be observed in both methods of

compaction – standard method and modified method. However,

samples compacted with the use of modified Proctor method,

the curve

CBR

(

w

) definitely reaches maximum. The shape of

the curves

CBR

d

(

w

) is similar to that obtained according to the

standard method –

CBR

(

w

). In the case of modified compaction,

curves

CBR

d

(

w

) and

CBR

(

w

) are characterised by a similar

scope of moisture content; from

w

opt1

–5% to optimum moisture

content,

w

opt1

(difference in relation to

CBR

– up to about

2.5%). Once curve

CBR

d

(

w

) exceeds

w

opt1,

it also exceeds

standard curve, passing

CBR

by 16% at

w

opt1

+5%. In the case of

standard compaction, at moisture level

w

opt2

–5%,

CBR

d

value

equals

CBR

value. After this, as the moisture content increases

the difference also increases and when the moisture level is

equal to

w

opt2

, the

CBR

difference is exceeded by 5%.

CBR

MP

= –1026.64 + 59.09

w

– 0.82

w

2

CBR

d MP

= – 467.44 + 27.46

w

– 0.37

w

2

CBR

SP

= – 297.17 + 16.96

w

– 0.22

w

2

CBR

d SP

= – 519.42 + 25.88

w

– 0.30

w

2

(

R

2

=0.8751)

(

R

2

=0.7768)

(

R

2

=0.8047)

(

R

2

=0.8468)

Figure 2.

CBR

test results versus moisture content at compaction in

comparison with compaction curves: MP – Modified Proctor method,

SP – Standard Proctor method,

CBR

– static test results,

CBR

d

–

dynamic test results.

With further increase of moisture content, the difference may be

as high as 13%. Significant differences in the results of the

studies carried out by means of static and dynamic methods, at

moisture level exceeding

w

opt

originate from the differences in

speed of loading and lack of possibility of pore pressure