565

Technical Committee 102 /

Comité technique 102

0

10

20

30

40

50

60

70

80

90

100

0.001

0.01

0.1

1

10

Percent Passing

Particle Size (mm)

Poorly

Graded Sand

Sandy Clay

Silty Sand

Table 2. Properties of the Test Soil

4 TEST DATA INTERPRETATION

Figure 3 shows the results from the testing using four

different run times. Based on the results from previous

testing in a sand pit, Gabr et al. (2012) evaluated a critical

stream power (P

c

) value = 24 Watts/m

2

for a sand with D

50

=

0.30 mm. Using a similar technique of extrapolation

approach, the data in Figure 3 is extrapolated to zero

penetration rate to yield an average P

c

value of 16 Watts/m

2

for the test soil. Similar to the observation by Gabr et al.

(2012), a minimum of “45 sec” run time is needed to provide

a reliable measurement of the penetration rate. To calculate

critical shear velocity from the P

c

, the following equation is

used (Annandale, 2006):

qh P

c

(2)

where, γ is unit weight of water, q is the discharge per unit

area, and h is the hydraulic head including the jet velocity

head.

0

0.5

1

1.5

2

2.5

3

3.5

10

100

Penetration rate (cm/s)

Stream Power (Watts/m

2

)

Run time = 15s

Run time = 30s

Run time = 45s

Run time = 60s

Figure 3. Extrapolation of the Stream Power to Assess

Critical Stream Power Value (P

c

)

Using Equation 2, a critical velocity is back calculated as

0.32 m/s corresponding to a critical stream power value of 16

Watts/m

2

. As flow field changes around the pier, and

therefore the flow-related shear stress, the shear stress below

which no scour is assumed to take place is estimated using

the equation proposed by Briaud et al. (1999):

)

10

1

log

1 (

094 .0

2

max

e

R

V

where, ρ is water density, R

e

= VD/υ is Reynolds number, V

is depth average flow velocity at the location of the pier if the

bridge were not there, D is pier diameter and υ is kinematic

viscosity of water. In this case, assuming a pier diameter of 1

m and a depth of flow= 2 m, the critical shear stress value is

estimated equal to 1.75 Pa.

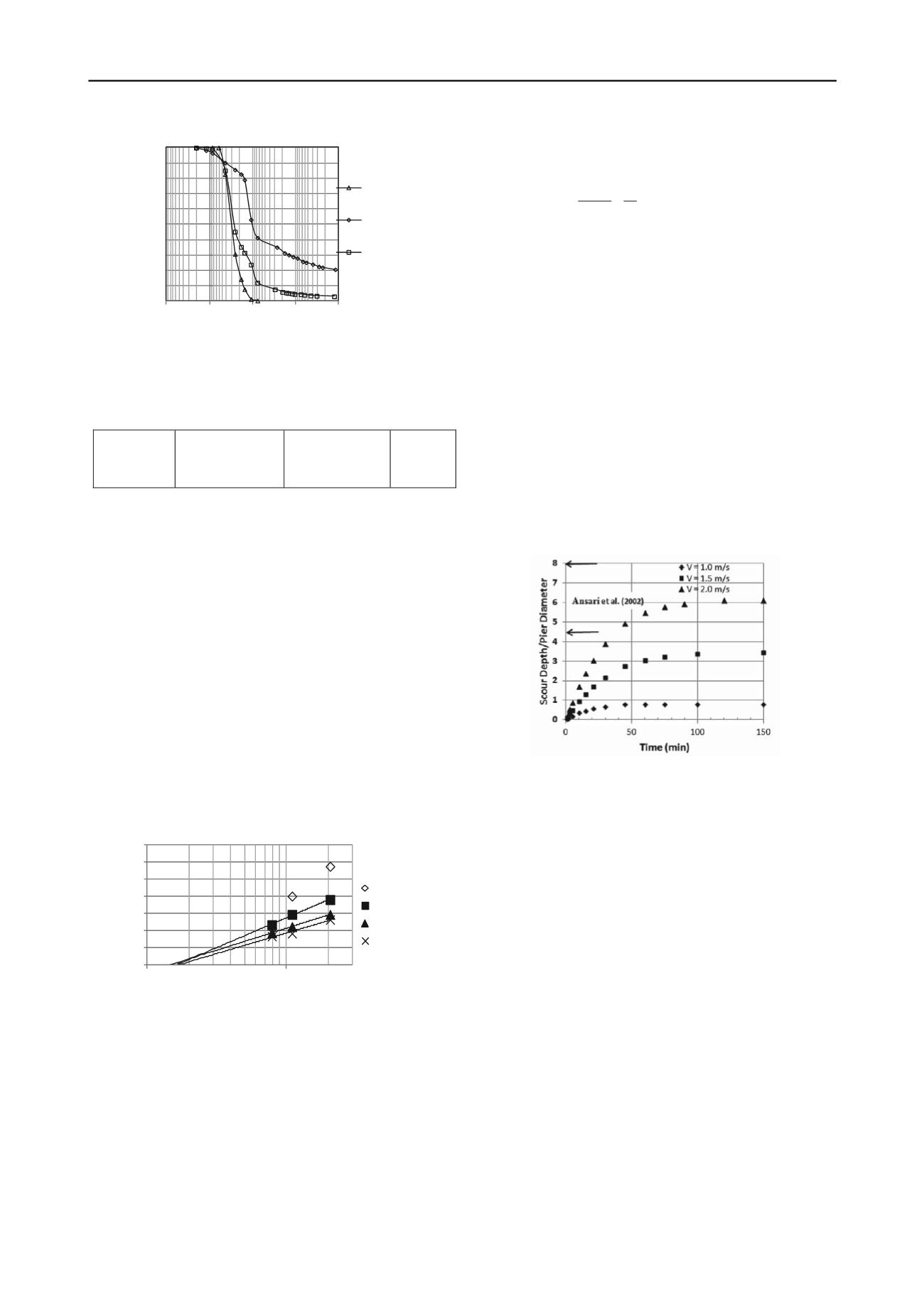

Figure 4 shows the equivalent penetration rate per shear

stress function for the averaged test data. During testing, the

probe tip is in close proximity of the soil mass, and erosion

occurs within the jet potential core. The applied shear stress

in this case is estimated using the relationship presented by

Annandale (2006) as:

2

UC

f

(4)

where:

= applied shear stress to bed in N/m

2

, U = average

velocity of water at the tip (m/s),

= density (kg/m

3

), and C

f

is a friction coefficient = 0.016 according to Annandale

(2006).

Figure 4. Computed Scour Around Circular Bridge Pier on Silty

Sand Bed; Range between Arrows is Values Estimated using

Empirical Equation

.

The slope of the data for the 45 and 60 secs in Figure 3

provides a parameter equivalent to the detachment rate

coefficient (k

d

) proposed by Mehta (1991). The k

d

values of

0.017 cm/sec per N/m

2

and 0.015 cm/sec per N/m

2

are

estimated, respectively, for the test soil at run times of 45 and

60 seconds. In comparison, k

d

values of 0.017 cm/sec per

N/m

2

and 0.013 cm/sec per N/m

2

were observed respectively

for sand at run times of 45 and 60 seconds by Gabr et al

(2012). The K

d

value obtained at 60 sec for the test soil is

approximately 13% higher than the value obtained for sand.

This observation agrees with the conclusion made by Ansari

et al. (2002), where the authors indicated that in a lower fines

content (<20%) type of soil, non-plastic fine particles are

carried away as the resistance due to “cohesion” becomes

insignificant.

5 SCOUR AROUND BRIDGE PIERS

Local scour around bridge piers occurs due to induced shear

stresses associated with flow field changes. Ettema et al.

Dry unit

weight

(kN/m

3

) =

17.7

Mean Particle

Diameter, D

50

(mm) = 0.26

Undrained Shear

Strength, C

u

(kPa)

=5-8

PI=

Non-

Plastic

Figure 2. Grain Size Distribution of Test Soil: Silty

Sand