2471

Technical Committee 211 /

Comité technique 211

5.2 Geogrids and fill material

For increasing the bearing capacity of the subsoil under the

foundation slab, geogrids are inserted as reinforcement. For

reinforcement three layers of geogrids with different properties

are placed in the fill material at different elevations.

The first layer of the geogrids was installed under the

middle section of the building where the contact pressure has

maximummean value up to P=100 kPa.The geogrids installed

on this position give the geotextile anadditional tensile strength,

as well as bursting and puncturing resistance.

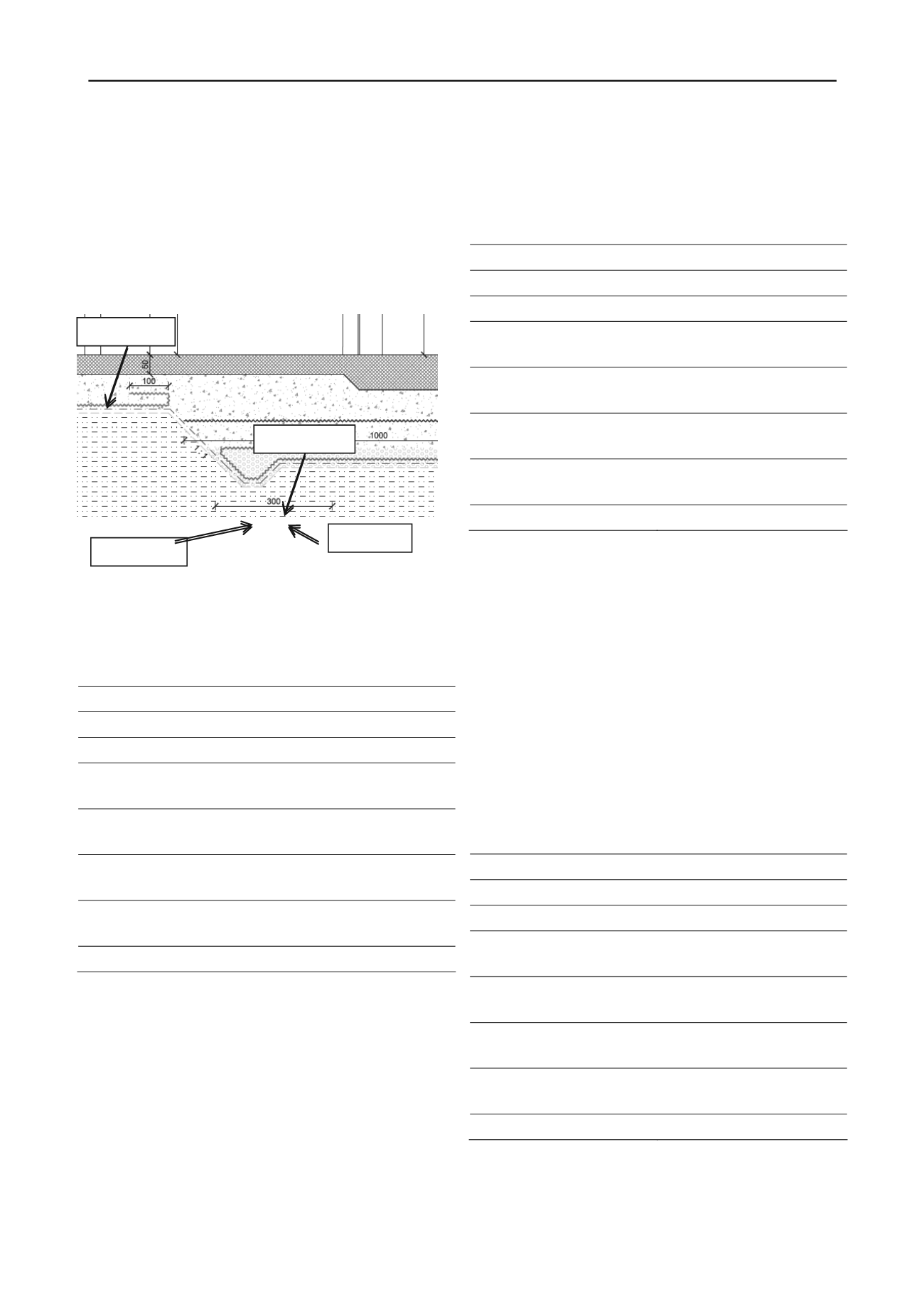

Figure 4. Cross section of the soil improvement measures

On other hand this first layer provides initial stiffness of the

low lifts of the fill material. The overlap oftwo adjacent panels

is 50 cm and anchoring length of 3.0 m. The properties of the

first layer of geogrid are shown in the Table 3.

Table 3. Properties of the geogrid 40/40 (first layer of geogrids)

Raw material

PP

Coating

Polymer

Weight

~ 330 gr/m2

Ultimate tensile strength

Longitudinal ≥ 40 kN/m

Transversal ≥ 40 kN/m

Tensile strength at 2% strain

Longitudinal ≥ 16 kN/m

Transversal ≥ 16 kN/m

Tensile strength at 5% strain

Longitudinal ≥ 32 kN/m

Transversal ≥ 32 kN/m

Strain at nominal tensile

strength

Longitudinal < 7%

Transversal < 7%

Mesh size

40 x 40 mm

Over this geogrid a layer of drainage fill material was

placed with thickness of 50 cm. This material has particlessize

from 16 to 32 mm.

This layer of drainage fill material is foreseen to reduce the

possibility of liquefaction. So in case of earthquake, the

building up of the pore water pressure will be reduced by

draining the water from the subsoil layers into the drainage

layer placed with the subsoil replacement works.

Over this drainage fill material, another geogrid was placed

but this time with higher strength properties. The use of this

geogrid is to reinforce the fill material as well as to ensure

additional stiffness, which is gradually increasing from the

bottom of the excavation pit up to the foundation slab.

Furthermore, this geogrid will ensure reaching of the requested

modulus of compressibility of the upperlayers of fill material.

The properties of the second layer of geogrid are shown in the

Table 4.

Table 4. Properties of the geogrid 80/30 (second layer of geogrids)

Raw material

PET

Coating

Polymer

Weight

~ 350 gr/m2

Ultimate tensile strength

Longitudinal ≥ 80 kN/m

Transversal ≥ 30 kN/m

Ultimate tensile strength at

3% strain

Longitudinal ≥ 22 kN/m

Ultimate tensile strength at

5% strain

Longitudinal ≥ 40 kN/m

Strain at nominal tensile

strength

Longitudinal < 8.5%

Transversal < 8.5%

Mesh size

20 x 20 mm

Geogrid 20/20

Geogrid 80/30

On top of the second geogrid two lifts of fill material are

done with thickness of 30 cm, total of 60 cm. The required

modulus of compressibility on top of these two layers of fill

material should be at least 100 MPa and minimum 98%

compaction after Proctor. The fill material is crushed stone base

aggregate.

On the extended parts of the building where the contact

pressure has maximummean value up to P=20 kPa, also a

geogrids is installed. This geogrid has an ultimate tensile

strength of 20 kN/m in both directions. The overlap of two

adjacent panels is 60 cm and the anchoring length is 1.0 m.

After installation of this geogrid the fill material is placed and

compacted in 30 cm thick lifts. The final layer of the fill

material at the extended parts of the building should reach at

least 80 kPa and minimum 98% compaction after Proctor.

After completion of the earth works ground improvement

measures were completely finished. So the works for hydro

insulation and constructing the structure commenced.

Table 5. Properties of the geogrid 40/40 (first layer of geogrids)

Raw material

PP

Coating

Polymer

Weight

~ 190 gr/m2

Ultimate tensile strength

Longitudinal ≥ 20 kN/m

Transversal ≥ 20 kN/m

Tensile strength at 2% strain

Longitudinal ≥ 8 kN/m

Transversal ≥ 8 kN/m

Tensile strength at 5% strain

Longitudinal ≥ 18 kN/m

Transversal ≥ 18 kN/m

Strain at nominal tensile

strength

Longitudinal < 7%

Transversal < 7%

Mesh size

40 x 40 mm

Geogrid 40/40

Geotextile