2470

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

sediment nature. In order to get precise geotechnical profile of

the ground, extensive geotechnical field investigations were

conducted. On the other hand, soil samples were taken for

laboratory testing. With such extensive scope of field

investigations, clear view of the ground profile was obtained.

Based on the performed field investigation works, it was

concluded that the site is composed of different layers of

sedimentary soils. With foreseen depth of the boreholes, no

bedrock was detected. On this site there is vast variety of soil

materials, from gravels and sands to silts and clays. Because of

the high heterogeneity of the ground profile, layers are grouped

into two extinguishing layers. The surface layers are low

plasticity clays and clayey sands, which are highly compressive

and they are present up to approximately 2.0 m from the

surface. While the next deeper layer is clayey sand with higher

compaction than the previous layer, and they are present up to

10.0 m from the surface. It is supposed that this second layer

continues up to depth for which loading stresses have impact on

the settlements.

According to the conducted field and laboratory tests,

present soil materials are loose and they have very poor strength

properties. In addition, the level of ground water table is very

high, approximately 1.0 m from the ground surface, because of

the nearby Ohrid Lake.

Table 1. Geomechanical properties

Soil

Fill Material

CL/SFc

SFc

g

(kN/m

3

)

22.0

18.4

18.5

c(kN/m

2

)

0.0

15.0

10.0

f

(

0

)

35.0

10.0

20.0

Mv (kPa)

80000.0

5000.0

10000.0

SPT

/

4

13

Considering all these facts, it is obvious that ground

improvement is necessary under the foundation of the new

construction. Moreover, the problem with the settlements is

inevitable, so the serviceability of the construction is also an

important issue.

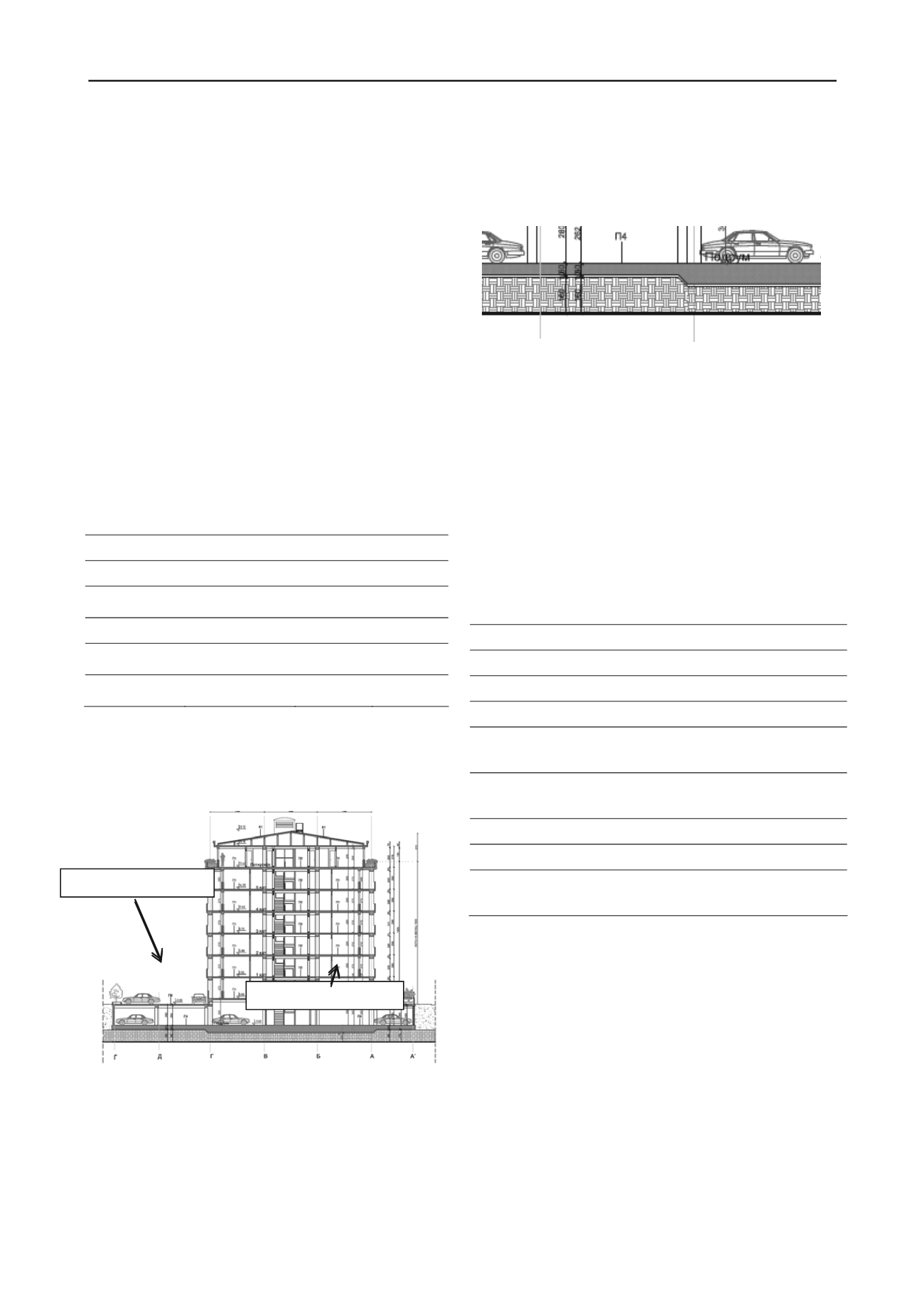

Figure 2.Adora building – cross section

4 CONSTRUCTION DETAILS

The Adorabuildingis built on the sitewhich is very close to the

Ohrid Lake. The superstructure of the building has 5 floors and

the substructure has 1 floor (see Figure 2). The substructure is

extended out of the superstructure and it is actually a parking

lot. The size of the superstructure in plan view is 52.0x22.0 m,

and the total size of the building (including the extensions of the

substructure) is 69.0x41.5 m. The foundation slab under the

superstructure is 0.9 m thick and on the extension parts it is 0.5

m thick.The contact pressure transferred on the subsoil varies in

range between 100 kPa (on cross-sectionsin the middle of the

building) and 20 kPa (on cross-sections in the extensions).

Figure 3. Cross section of the foundation structure

5 THE SOLUTION

As it was mentioned before, the improvement of the subsoil was

done by means of soil replacement and usage of geosynthetic

materials.

Because of the foundation level of -1.5 m from the ground

surface and the depth of soil replacement of 2.0 m, total of 3.5

m deep foundation pit was excavated. The excavation pit was

done by constructing2:1 slopes. In addition, dry conditions for

execution of the construction works in the excavation pit were

ensured by dewatering the excavation by extraction wells. On

the other hand the excavation pit had greater dimensions in plan

view, 2.0 m greater than the contours of the foundation slab.

Hence the loading stresses can be spread in the fill material by

angle of max 45°.

Table 2. Properties of the geotextile

Raw material

PP multicolored/PET

Method of production

Mechanically bonded

Weight

≥ 300 gr/m

2

Thickness under 2 kPa load

≥ 3 mm

Ultimate tensile strength

Longitudinal ≥ 4.0 kN/m

Transversal ≥ 7.5 kN/m

Strain at ultimate tensile

strength

Longitudinal 120% (±40%)

Transversal 80% (±40%)

CBR puncture resistance

≥ 1300 N (-300 N)

Opening size O90

0.10 mm (±0.02 mm)

Water permeability index

normal to the plane

85 x 10-3 m/s

(-15 x 10-3 m/s)

Fondation slab 0.5 m

5.1 Geotextile

Fondation slab 0.9 m

At the bottom of the excavation pit, geotextile was used to

ensure separation of the fill material from the subsoil. By the

separation, it is meant that the geotextile will prevent mixing of

the different soils, but it will enable complete water

permeability, so with this, complete preservation of the

properties of the later placed fill materials will be ensured. Used

geotextile has the physical and mechanical properties, listed in

the Table 2.

The geotextile was placed all over the bottom of the

excavation pit as well as on the excavation slopes. The overlap

oftwo adjacent panels is 60 cm, and it completely wraps the fill

material up. Used geotextile with the properties given in the

Table 2 has the ability to withstand burst and puncture, and has

enough tensile strength to serve a separation function, without

being destroyed.