2401

Technical Committee 209 /

Comité technique 209

silty sand, a normal consolidation stress of 100 KPa was applied

in one step for all the specimens.

1.4

Cyclic Direct Simple Shear test results

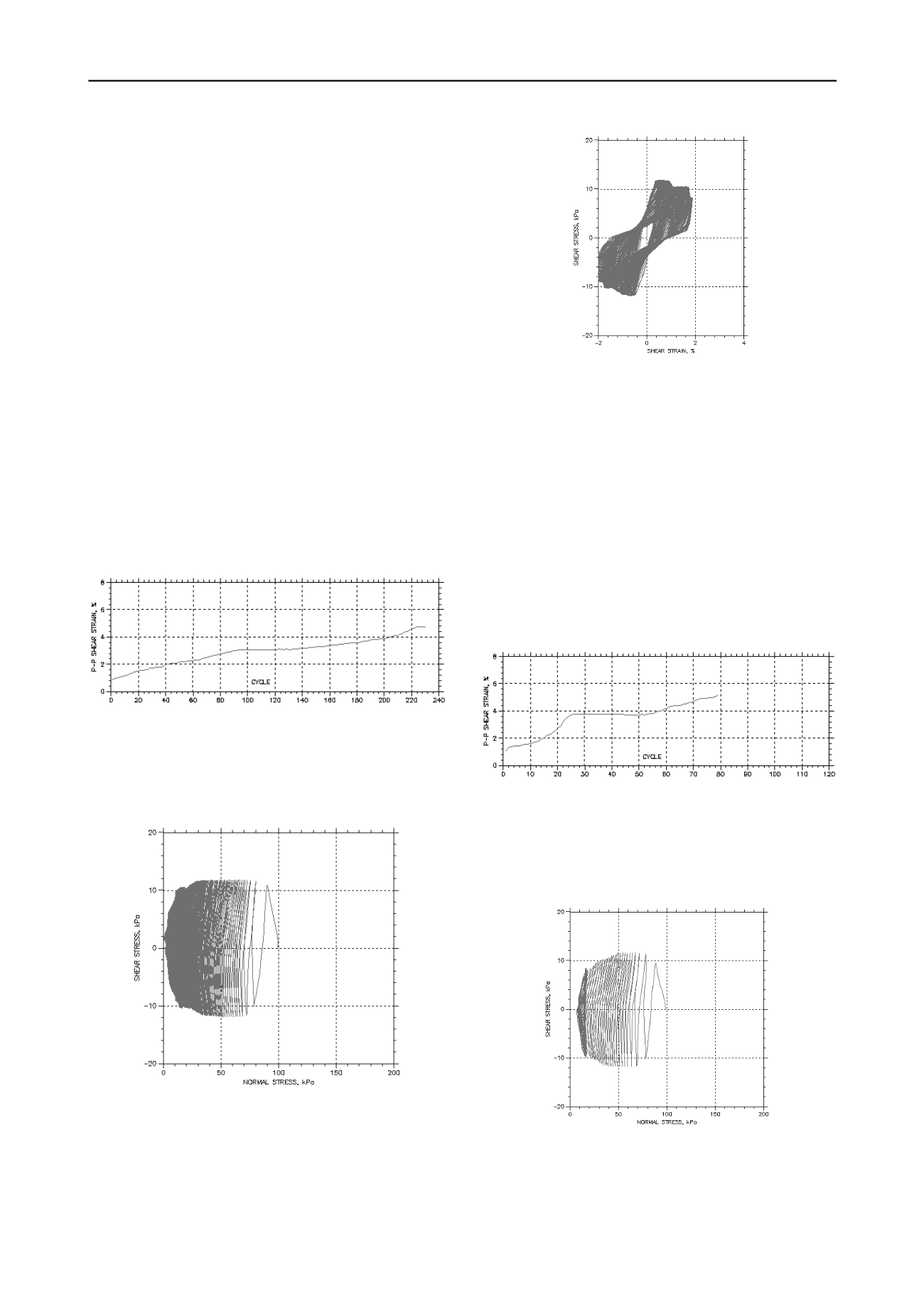

Several researchers have used different shear strain failure

criteria such as 3%, 4%, 5% and 7.5%. A shear strain failure

condition was used for tests performed on marine silty sand and

the failure criterion was established as 4% double amplitude

shear strain. The results of a test are shown in Figure 6, 7 and

8.Figure 8 shows the applied cyclic shear stress of +/- 12 kPa

(CSR = 0.12). Figure 6 shows the development of shear strain

throughout the test, which reaches 4% double amplitude shear

strain at nearly 205 cycles.

8 CDSS tests were conducted, 4 tests at voids ratio of 0.898

(Dr 65%) and CSR range of 0.10, 0.12, 0.14, and 0.16. 4 tests at

voids ratio of 0.847 (Dr 70% and CSR range of 0.10, 0.12, 0.14,

and 0.20. All the tests were conducted at nominal initial

effective confining stress of 100 kPa to provide a basis for

comparison between tests. In case of 70% relative density,

Figure 6 shows the degradation curve and development of shear

strain with increasing number of cycles. In a general sense,

marine silty sand specimens seem to exhibit gradual increase in

shear strain and degradation of shear stiffness with increasing

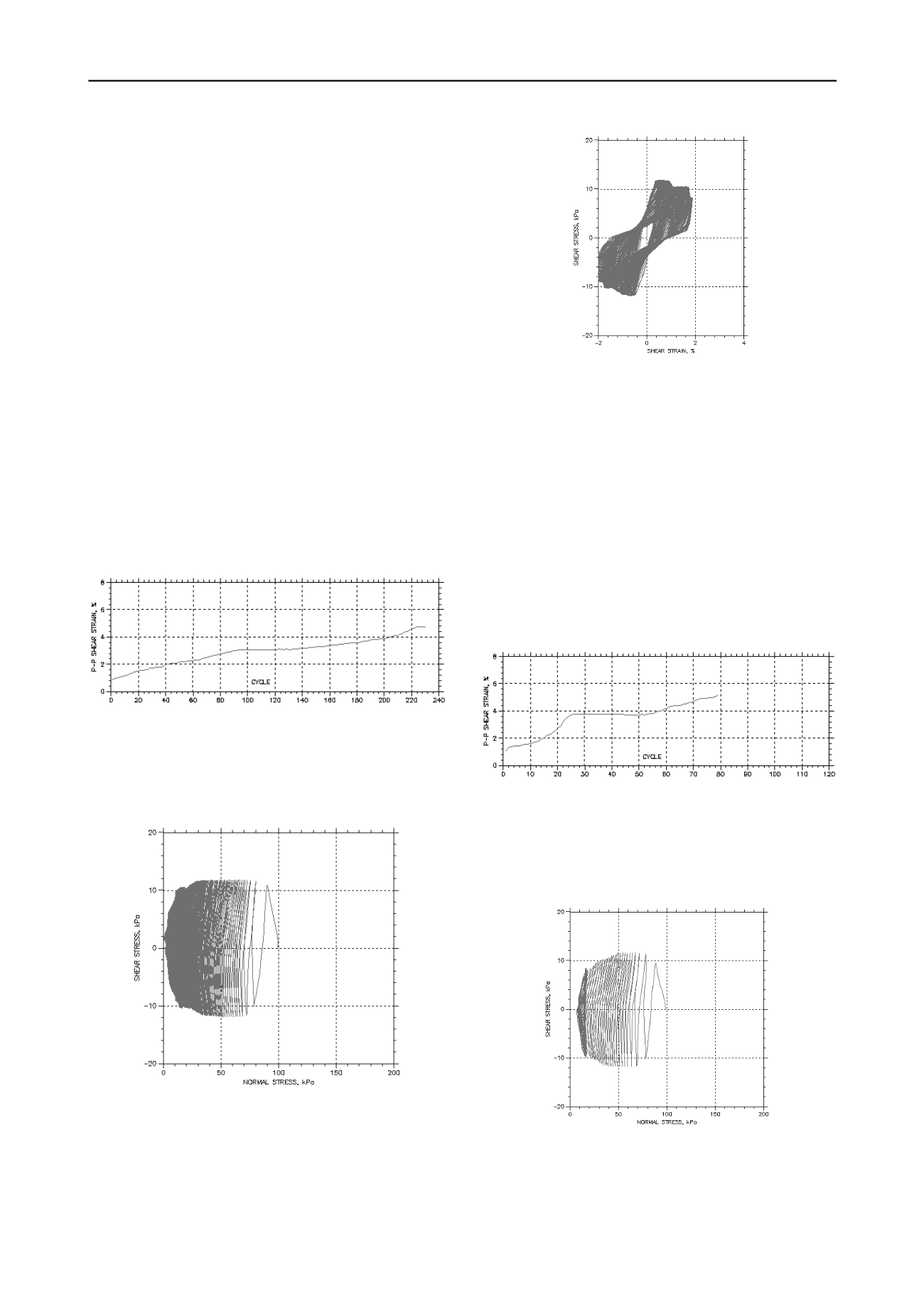

number of load cycles. Typical stress paths and stress-strain

curves of tests conducted on marine silty sand specimens are

presented in Figures 7 and 8 respectively.

Figure 6 Peak-Peak Shear Strain vs No. of Loading cycles for (σ’

v

= 100

kPa, CSR=0.12 and Dr (%) = 70).

Figure 6 shows that samples having relative density of 70%

reached 2% cyclic double amplitide cyclic shear strain after 42

cycles and 205 to reach failure.

Figure 7 Stress Path During constant volume cyclic DSS loading of silty

sand for (σ’

v

= 100 kPa, CSR=0.12 and Dr (%) = 70).

Figure 8 Stress-strain response of marine silty sand under constant

volume cyclic DSS loading (σ’

v

= 100 kPa; Dr (%) = 70, CSR = 0.12;

α= 0.0; OCR = 1.0).

In case of 65% relative density, Figure 9 shows the

degradation curve and development of shear strain with

increasing number of cycles. Typical stress paths and stress-

strain curves of tests conducted with 65% relative density on

marine silty sand specimens are presented in Figures 10 and 11

respectively.

It was observed that specimens having higher relative

densities require higher no. of loading cycles to reach 4%

double amplitude cyclic shear strain and specimens having

lower relative density reach to failure in smaller no. of loading

cycles. In case of higher cyclic stress ratio (CSR) the soil

samples reached the failure criterion in few no. of loading

cycles.

Figure 9 Peak-Peak Shear Strain vs No. of Loading cycles for (σ’

v

= 100

kPa; Dr (%) = 65, CSR = 0.12; α= 0.0; OCR = 1.0).

Figure 9 shows that samples having relative density of 65%

reached 2% cyclic double amplitide cyclic shear strain after 15

cycles and 57cycles to reach failure.

Figure 10 Stress Path During constant volume cyclic DSS loading of

silty sand for (σ’

v

= 100 kPa; Dr (%) = 65, CSR = 0.12; α= 0.0; OCR =

1.0).