1334

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

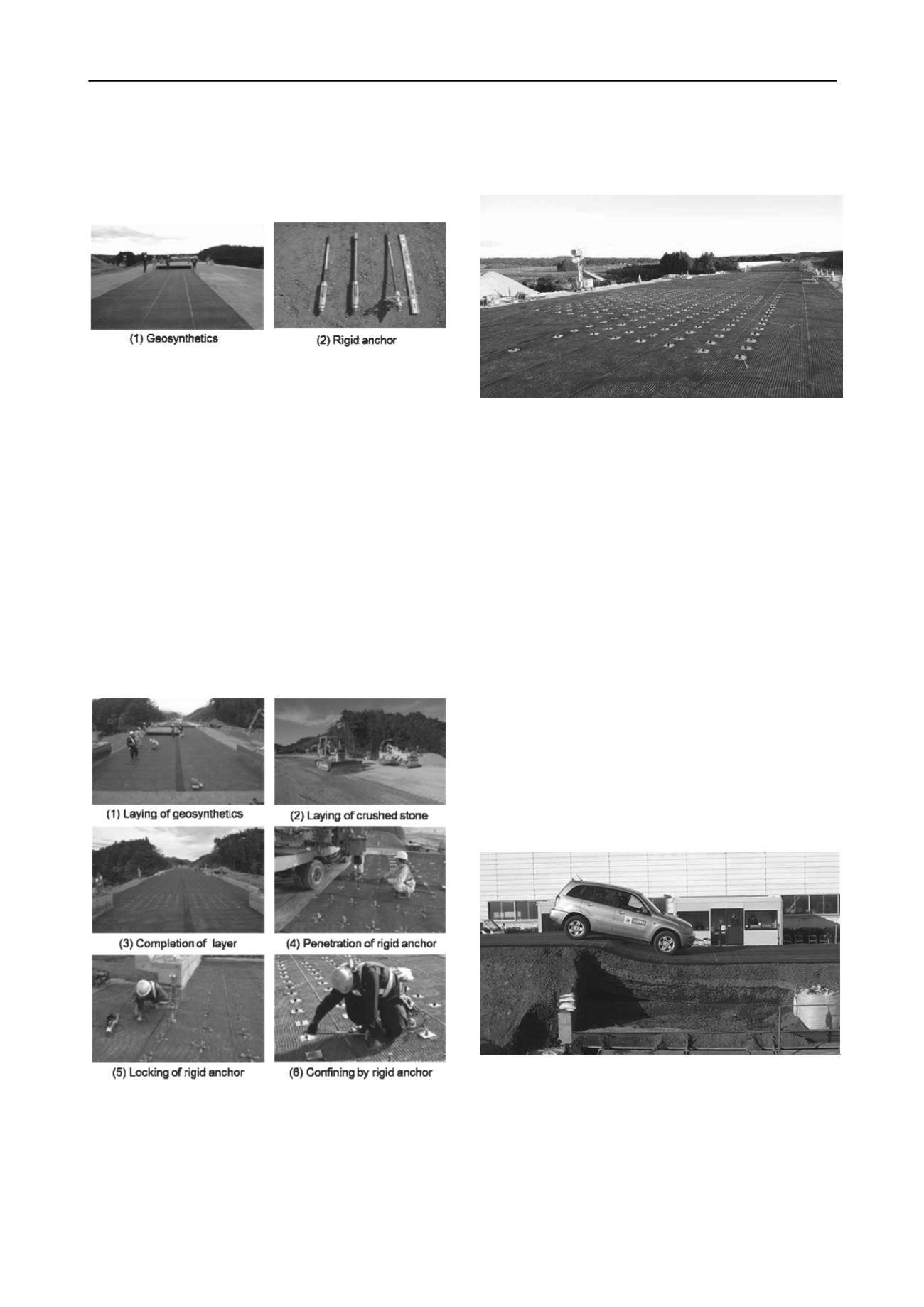

Photograph 1 (2) shows the newly developed post-tensioning

rigid steel anchor used in CRE. This anchor was improved

from a slope reinforcement anchor. The anchors is vertically

penetrated from the top to the bottom layer and locked to the

lower geosynthetics.

Photographs 1. Geosynthetics and confining rigid steel anchors using

Confined-Reinforced Earth.

3 CONSTRUCTION METHOD

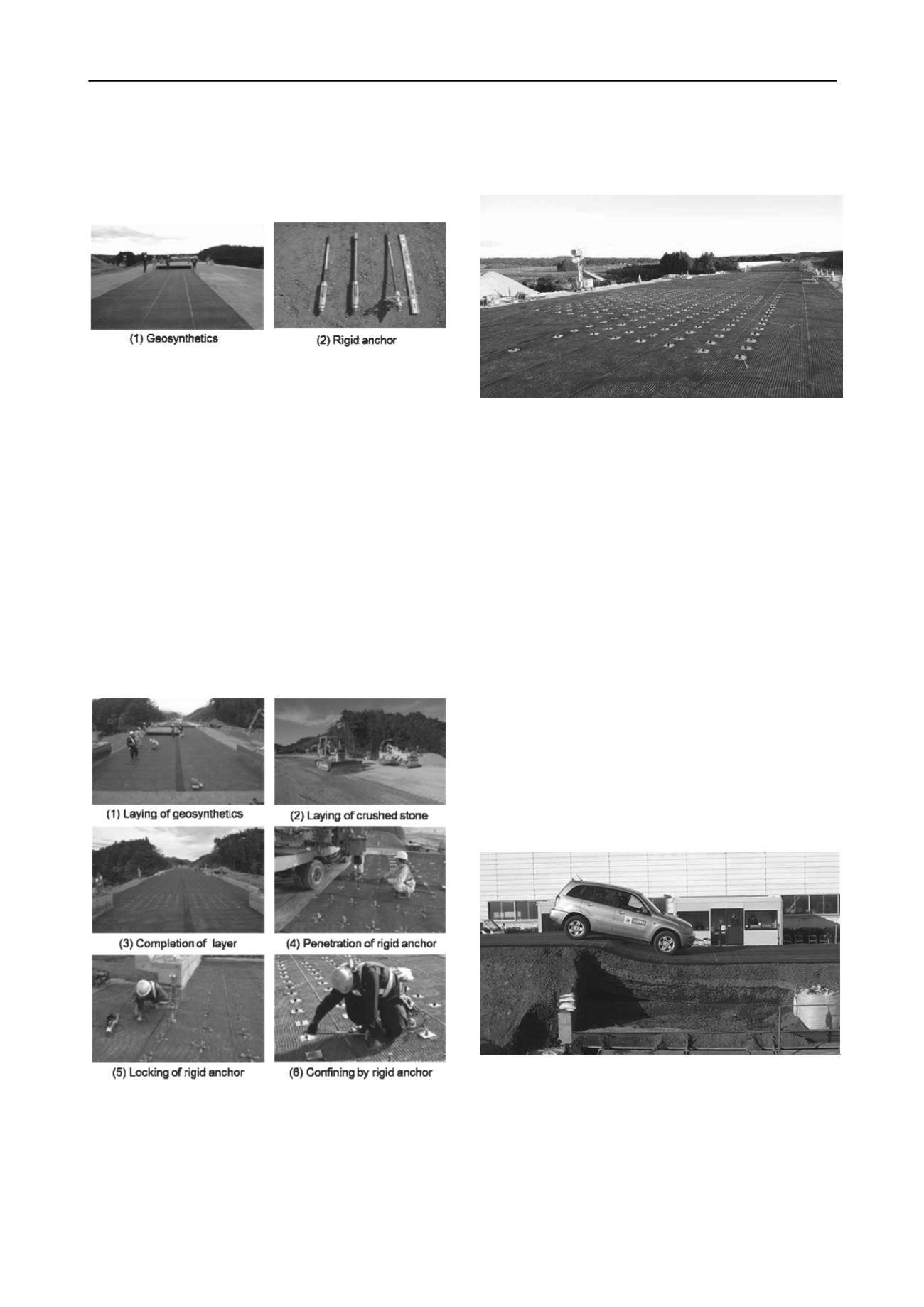

Photographs 2 show the construction sequence of CRE. After

preparing the lower subgrade, the 1

st

layer of geosynthetics is

laid on the area to be reinforced (Photograph 2 (1)).

Then crushed stones are carefully laid by a bulldozer or by a

motor grader (Photograph 2 (2)) on the 1st layer of

geosynthetics and the layer of crushed stone is fully compacted

by vibrating rollers (Photograph 2 (2)). After placing three

layers of compacted crushed stone and laying of 2

nd

,3

rd

and 4

th

layers of geosynthetics (Photograph 5 (3)), rigid steel anchors

are vertically penetrated from the top to the bottom layer by the

small pile driving equipment (Photograph 2 (4)) and

mechanically locked to the lower geosynthetics employing a

small hydraulic jack ( Photograph 2 (5)).

It should be noted that the construction time of setting

anchors is very short (about 40 to 50 anchors per hour). Finally,

a top steel plate is set through a rod and is fixed to the rod

Photographs 2. Construction method of Confined-Reinforced Earth.

(Construction in Joban Highway in Fukushima, Japan, 2011)

with a nut using a torque wrench (Photograph 2 (6)). Confining

load of 30kN can be exactly maintained by setting torque. By

use of this construction method, rapid construction of CRE

becomes possible making it practical enough to apply this CRE

for road in service. Photograph 3 shows the application of CRE

for seismic retrofit of asphalt pavement on the actual highway

embankment in Joban Highway, Fukushima, Japan, constructed

in 2011.

Photograph 3. Application of Confined-Reinforced Earth for actual

highway embankment in Joban Highway, Fukushima, Japan, 2011.

4 FULL SCALE IN-SITU TEST

4.1 Trial embankment

A full-scale test of this high rigidity reinforced earth was carried

out in the field in Ibaraki, Japan, from 9

th

to 16

th

March 2011 as

shown in Photograph 4. The constructed trial embankment was

of 25m length, 4m width and 2.5m height at the top of

embankment. Full-scale asphalt pavements were placed on the

trial embankment. The asphalt concrete pavement consisted of

asphalt concrete of 50mm thickness and base course of 300mm

thickness. Two types of asphalt pavement were constructed. The

first type was conventional asphalt concrete pavement placed on

the compacted soil subgrade, while the second was asphalt

pavement placed on the high rigidity confined-reinforced earth

consisting of the crushed stone sandwiched by four layers of

geosynthetics and confined by confining rigid anchors.

We aimed at direct comparison of performance of the two

pavement types by artificially generating the differential

settlement of trial embankment such as often seen during severe

earthquakes. The forced differential settlement of the

embankment was realized by using 10 multi-controlled large

hydraulic jacks supporting the steel deck (10m long) placed

under the embankment body. The layout of the trial

embankment is shown in Figure 2.

Photograph 4. Trial embankment after testing of 550mm differential

settlement. (Confined –Reinforced Earth tested in Ibaraki, Japan,

2011)