1127

Technical Committee 106 /

Comité technique 106

0

50

100

150

0

100

200

300

400

500

600

Small-strain shearmodulus,Gmax (MPa)

Net confining pressure,(p-u

a

): kPa

s = 400 kPa (RC)

s = 400 kPa (BE)

s = 200 kPa (RC)

s = 200 kPa (BE)

s = 50 kPa (RC)

s = 50 kPa (BE)

G

max

= A(p-u

a

)

B

s : kPa

A

B

R

2

50

3.316 0.535 0.99

200

7.863 0.471 0.98

400

10.988 0.368 0.90

5 DYNAMIC SHEAR MODULUS AND DAMPING

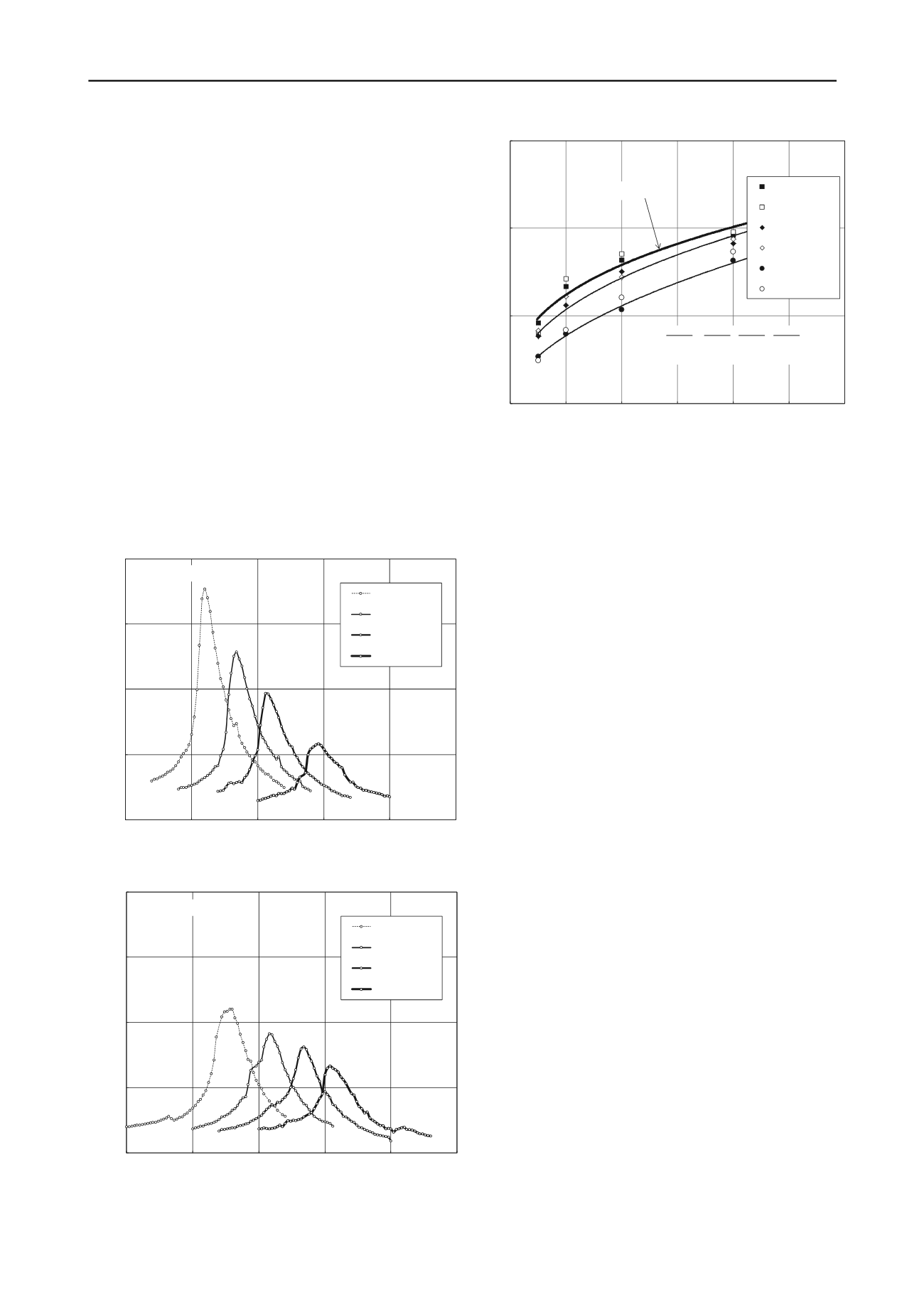

Figure 4 shows the variation of small-strain shear modulus G

max

(from both RC and BE tests) with net confining pressure, and

for different suction values. The trends confirm those shown in

Figure 3: suction is observed to have a significant influence on

soil stiffness, though not as pronounced as that of net confining

pressure. The BE technique yields G

max

values reasonably close

to those obtained via resonant column testing. Solid lines in

Figure 4 represent best-fit power regression functions of the

form, G

max

= A(p – u

a

)

B

. Constant A represents the value of

G

max

(MPa) at net confining pressure, (p – u

a

) = 1 kPa; while

constant B is the slope of the best-fit curve, which represents

how susceptible soil stiffness is to changes in net confinement

(p – u

a

).

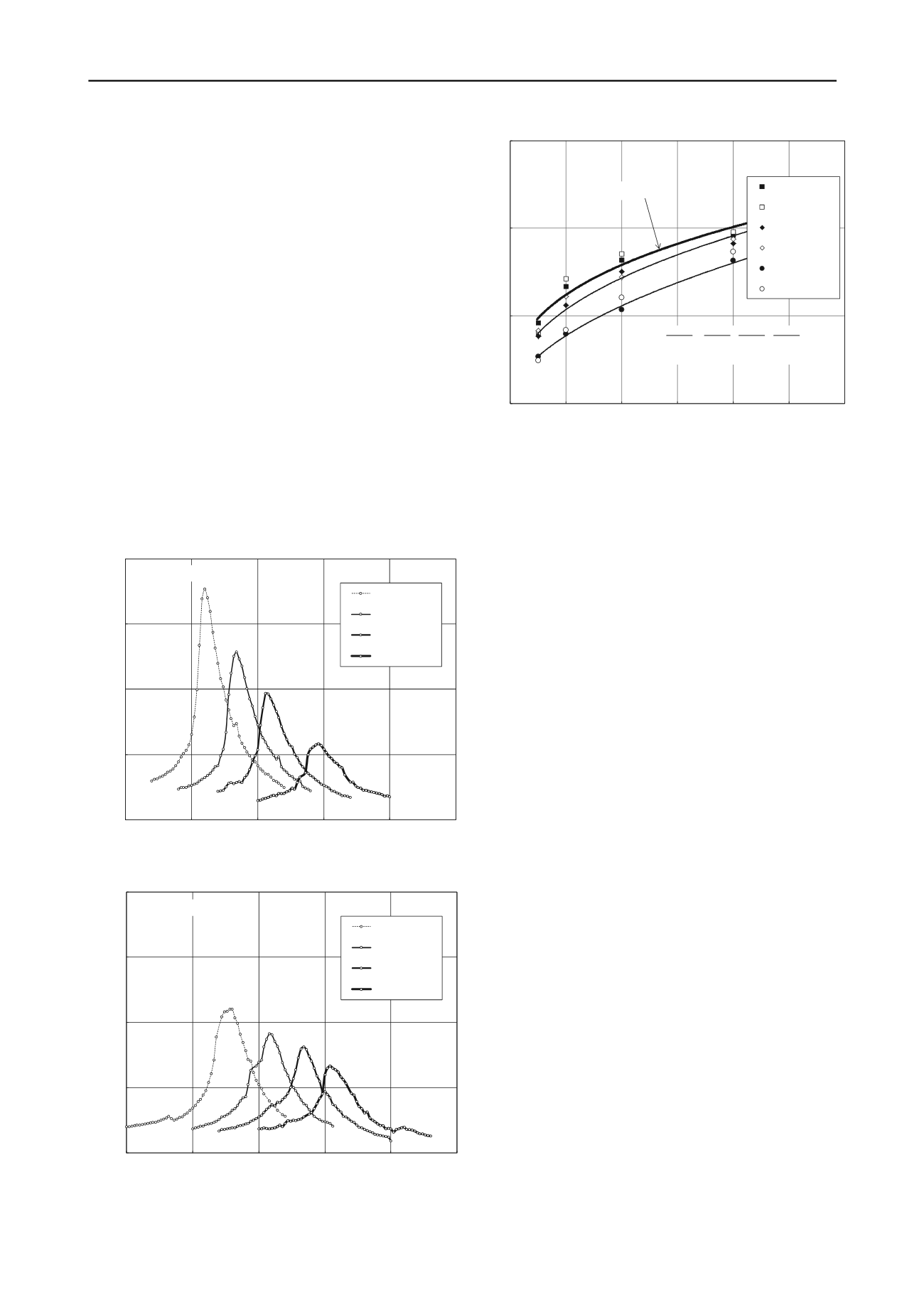

0.0000

0.0005

0.0010

0.0015

0.0020

50

100

150

200

250

300

Shearstrain (%)

Frequency (Hz)

(p-ua) = 50 kPa

(p-ua) = 100 kPa

(p-ua) = 200 kPa

(p-ua) = 400 kPa

(a) s = 50 kPa

During bender element testing, the first arrival of shear-wave

was taken as the point of zero crossing after the first inflection

of the received signal, which corresponds to the first arrival of

the shear-wave based upon experimental and numerical studies

(Lee and Santamarina 2005). The travel distance is taken as the

tip-to-tip distance L between bender elements, hence the shear-

wave velocity is computed as V

s

= L/t, where t = travel time.

Knowing V

s

and the total mass (bulk) density of the specimen

, the small-strain shear modulus can be determined as G =

(V

s

)

2

.

0.0000

0.0005

0.0010

0.0015

0.0020

50

100

150

200

250

300

Shearstrain (%)

Frequency (Hz)

(p-ua) = 50 kPa

(p-ua) = 100 kPa

(p-ua) = 200 kPa

(p-ua) = 400 kPa

(b) s = 200 kPa

Figure 3. Frequency response curves from SM soil at different net

confinement and suction states: (a) s = 50 kPa; and (b) s = 200 kPa.

modulus response of SM

Figure 4. Dynamic shear

soil at different net

confinements and matric suction states.

Figure 5 shows the change in small-strain damping ratio D

min

(from RC tests) with matric suction, for different net confining

pressures. Damping is calculated from logarithmic decay curves

using: D

min

= (1/2

n)log

e

(Z

o

/Z

n

); where, Z

o

= peak amplitude of

the first free-vibration cycle, and Z

n

= peak amplitude of the nth

cycle. The trends confirm those in Figure 3, with lower damping

(higher stiffness) at higher matric suctions. In general, material

damping tends to be overestimated by the half-power bandwidth

method: D

min

= (1/2)(f

2

– f

1

)/f

r

; where f

r

= resonant frequency.

The main focus of the present work has been on small-strain

stiffness of compacted silty sand. The cyclic behavior of soils,

however, is nonlinear and hysteretic; consequently, the shear

modulus and material damping are heavily strain dependent.

Figure 6 shows the cyclic hysteretic stress-strain loops from two

SM soil samples subjected to a cyclic 10-pfs input torque (1 kN-

m) at matric suctions, s = 50 kPa (thinner trace) and s = 200 kPa

(thicker trace), respectively; both under the same net confining

pressure, (p – u

a

) = 200 kPa. Equivalent viscous damping could

also be evaluated from the area enclosed by the cyclic hysteretic

loops. Therefore, the loops further substantiate the trends shown

in Figure 5, with smaller areas enclosed by the cyclic hysteretic

loops, and lower shear strains induced by the same cyclic shear

stress, with increasing matric suction.

6 CONCLUDING REMARKS

Suction-controlled resonant column tests on compacted SM soil

shows that the newly implemented proximitor-based RC device

is suitable for testing soils under controlled suction states via

axis-translation technique. Test results underscore the influence

of soil suction over the frequency response curves, logarithmic

decay curves, cyclic hysteretic stress-strain loops, and the small-

strain stiffness properties of compacted SM soil. Lower material

damping (higher stiffness) is observed at higher suction states.

In general, material damping tends to be overestimated by the

half-power bandwidth method. Simultaneous suction-controlled

bender element tests produced G

max

values reasonably close to

those from resonant column tests.

The general trends observed in this research effort are

similar to those previously reported for a more limited range of

test variables (e.g., Kim et al. 2003, Sawangsuriya et al. 2009,

Ng et al. 2009). The time frame and scope of the present work

did not contemplate investigating the effects of initial void ratio,

stress history, hydraulic hysteresis, or the impact of net normal

stress and/or suction history on the normalized G/G

max

and

D/D

min

response of SM soil. The authors are currently embarked

on a more thorough research effort to gain further insight into

all these dynamic aspects of unsaturated soil behavior, including