1048

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

wall positions. The PFC

2D

uses simple fluid coupling scheme

(Patankar, 1980) for incompressible viscous or inviscid flow on

a fixed rectangular grid aligned with and superimposed on the

Cartesian axes for the DEM model. The fluid flow in the PFC

2D

uses the numerical scheme of the Navier-Stokes’ equations. The

effects of solids on fluid motion are introduced to the numerical

scheme of the Navier–Stokes’s equations in terms of porosity

and coupling force averaged over each element (Bouillard et al.,

1989). Fluid-solids coupling time-step is 100 times larger than

individual particles collision time-step. The drag force applied

by all the particles in each fluid element to the fluid is defined

as:

b

f

U

(2)

where

b

f

=drag force applied to the unit volume of fluid,

=coefficient for flow,

U

=average relative velocity between the

particles and the fluid, defined as:

(3)

where

u

=average velocity of all particles in a given fluid

element,

v

=fluid velocity. Different expressions for coefficient

are given for porosities with values higher and lower than

e

=0.8 (Bouillard et al. 1989):

2 2

(1 ) (150(1 ) 1.75

);

0.8

f

e

e

d U e

d e

(4)

1.7

(1 )

4

;

0.8

3

f

d

U e

C

e

de

(5)

0.687

24(1 0.15Re )

;Re 1000

Re

0.44;Re 1000

p

p

p

d

p

C

(6)

Re

f

p

U ed

(7)

where

d

=average diameter of the particles occurring in the

element,

C

d

=turbulent drag coefficient defined in terms of

particle Reynolds number

Re

p

,

e

=porosity,

f

=fluid density,

=fluid dynamic viscosity. A fluid force equal and opposite acts

to the particles in each fluid element. The fluid drag force

applied to individual discrete particles is:

(8)

where

drag

f

=fluid drag force on the particle and

r

=particle

radius. The fluid-applied force acts at the particle center of

mass, and the rotational moment is not applied to the particle.

The resultant force that determines the individual particle

motion is the sum of the averaged fluid drag and individual

particle-particle or particle-wall collision forces and moments.

2.1.1 User defined lubrication contact model

The particle contact model in PFC2

D

is built to model the

elasto-hydrodynamic deformation of a solid elastic sphere that

is immersed in a viscous fluid and in close motion toward

another sphere or a wall. The model is based on the criteria for

predicting whether two solid particles will stick or rebound

subsequent to impact immersed in the fluid.

The lubrication force,

F(t)

act as contact force when two

spheres are approaching each other (Davis et al., 1986):

(9)

where

=fluid dynamic viscosity,

a

=particle radius,

v

=relative

approaching velocity of two particles and

x

=distance between

particle surfaces. Physically, the lubrication of a contact can be

viewed as a thin layer of viscous fluid that acts as a cushion

between two particle surfaces. It slows down the initial particles

velocities and decreases the kinetic energy of the particles. If

the balance of the lubrication force and the fluid approaching

velocities causes adjacent particles slowing down to near zero,

the

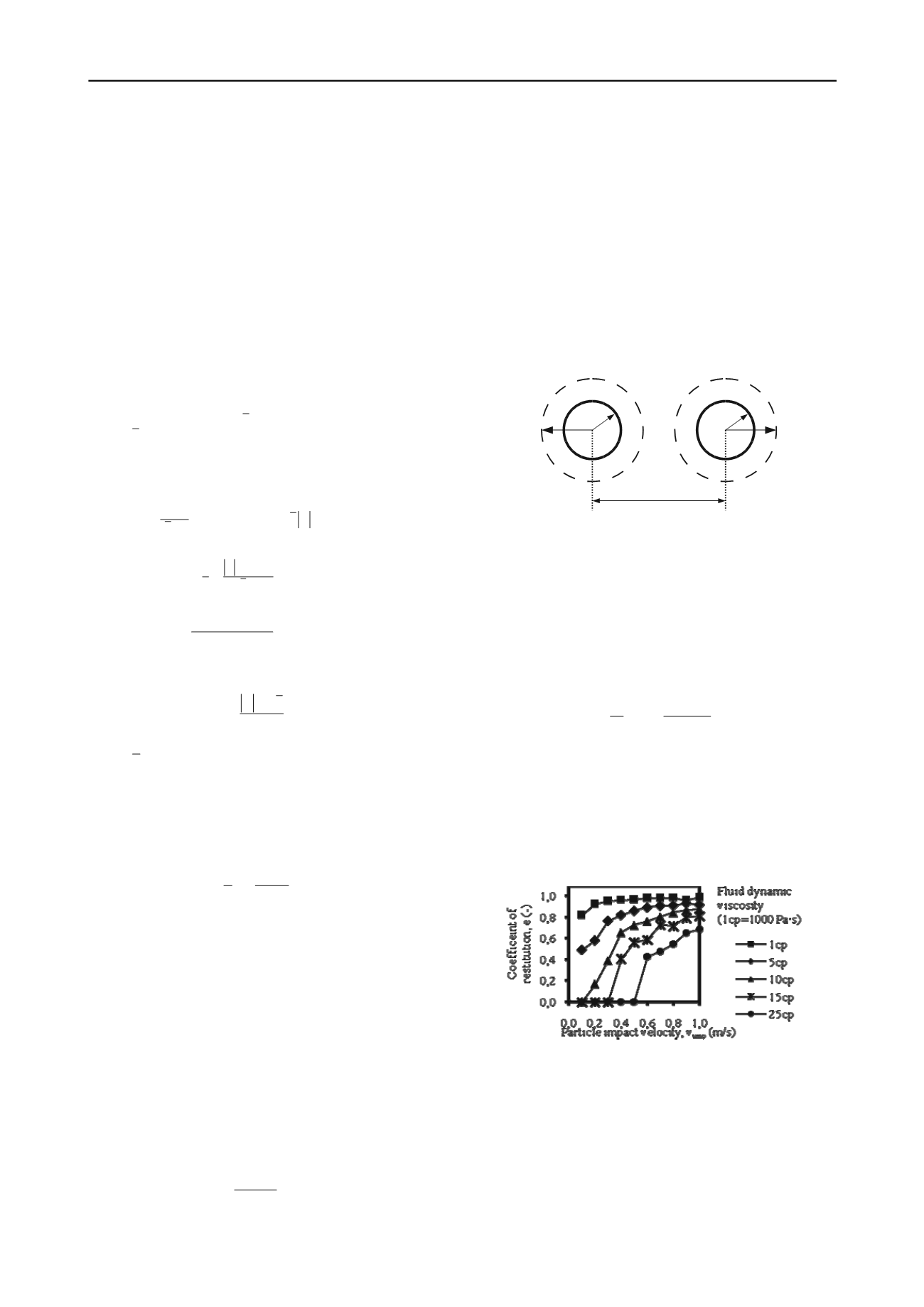

he active particle radius is represented in DEM by the apparent

radius that is bigger than the particle we want to model (Fig. 2).

particles may stick next to each other and get trapped with

the fluid and agglomerate.

The elastic rebound depends on the overlap of two particles

if they are in contact with the real radii (

r

ij

<r

c

) and the

lubrication damping force acts upon contact when it is activated.

T

RT

(

j

)

rij

RT

(

i

)

RI

(

j

)

RI

(

i

)

U u

v

Fig

on are activated. The

contact force logic can be written for PFC

2D

for the user defined

nd compiled in C++ as:

if

r

ij

≥ 2

r

c

=

crit

(10)

if

r

< 2

r

c

=

crit

(11)

r

c

=real particle radius,

=fluid

ynamic viscosity,

k

is the spring stiffness,

c

=dashpot constant,

and

lub

=lubrication constant.

ure 2. Schematic of the apparent (RI) and real (RT) radii and the

approaching distance,

r

ij

.

The apparent radius enables the activation of the contact and

calling the contact force when the particles approach each other

at a close distance. During the time-stepping procedure, if the

particles are close enough that they overlap with their real radii,

then the elastic rebound and the fricti

contact model, a

2

6

lub

( 2 )

ij

ij

ij

ij

c

v

v

F ma

a

ij

where

F

c

=contact force,

d

ij

=overlap of the particles,

r

ij

=distance

between the particles centers,

d

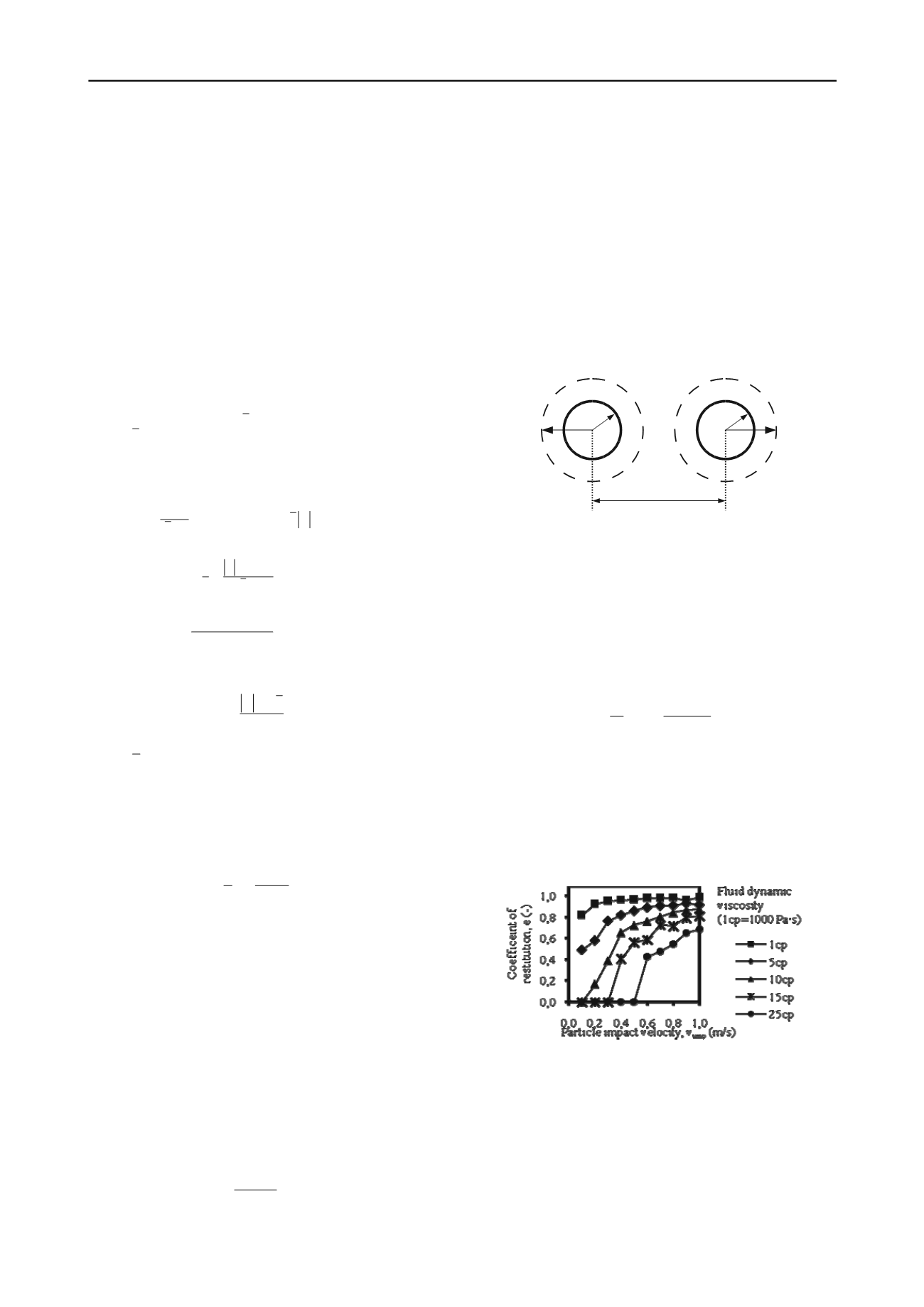

Figure 3. Particle drop test results for the sand particle with diameter

d=0.25mm using user-defined lubrication force contact model

The coefficient of restitution of this system is non-linear

curve dependent on the approaching velocity. Particle-particle

interactions are governed by the user-defined contact model,

and for the purpose of calculating their motion effect of fluid

motion in fluid-solids coupled scheme they are averaged in each

fluid cell (Eqn. 3). Fig. 3 shows the result of restitution

coefficient simulation in PFC

2D

using the developed user

defined contact model for collision between sand particle and

wall. Coefficient of restitution is the ratio between velocity after

c

x

r r

(2 )

c

c

ij

ij

F ma k r r cv

3

4

3 (1

b

drag

f

f

r

e

)

2

6 ( )

a v

F t

x