1049

Technical Committee 105 /

Comité technique 105

and before impact. At low approaching velocities lubrication

effect prevails and significantly decreases particle rebound

at higher impact velocities lubrication effect

lastic rebound so much.

was

est

nd concentrations. Fluid velocity

decreases with concentration increase, following similar paths

for all pressure differences.

velocity, while

does not affect e

3 RESULTS

A study of 30 mesh sand flow in a narrow 2 mm and 4 mm wide

and 0.5 m long channels reveals behavior of sand slurry flow

obstructed with particle-particle interactions and particle-wall

interactions caused by concentration and ratio of channel width

and particle diameter. The study is simplified with respect to

using a uniform particle size distribution and coarse

discretization of the CFD-DEM fixed grid. Only two grid

elements across the width of the narrow channel are able to be

used in CFD scheme in order to keep the accuracy of the

coupling with respect to the particle size. Boundary conditions

of the flow are constricted to the non-slip conditions at the

channel upper and lower boundary with zero fluid velocity, and

a pressure difference

P

between the enter and exit profiles of

the channel. Average fluid and sand velocites are measured

across some fixed volume in the channel after the flow

ablished. In a narrow channel, sand velocities are obstructed

by formation of particle packs and solids-wall interactions.

Velocity of sand is always smaller than velocity of

surrounding fluid, indicating that fluid flows arround the sand

particles or packs that move with the fluid, but at slower

velocity. Pressure and sand concentration effect on sand

velocity in the narrow channel is studied. Fig. 4 shows the

change of sand velocity under different presssure differences

and sand concentrations. Average sand velocity in the channel

decreases with particle concentration increase, but does not

follow the same law for higher and lower (dp<500Pa) pressures.

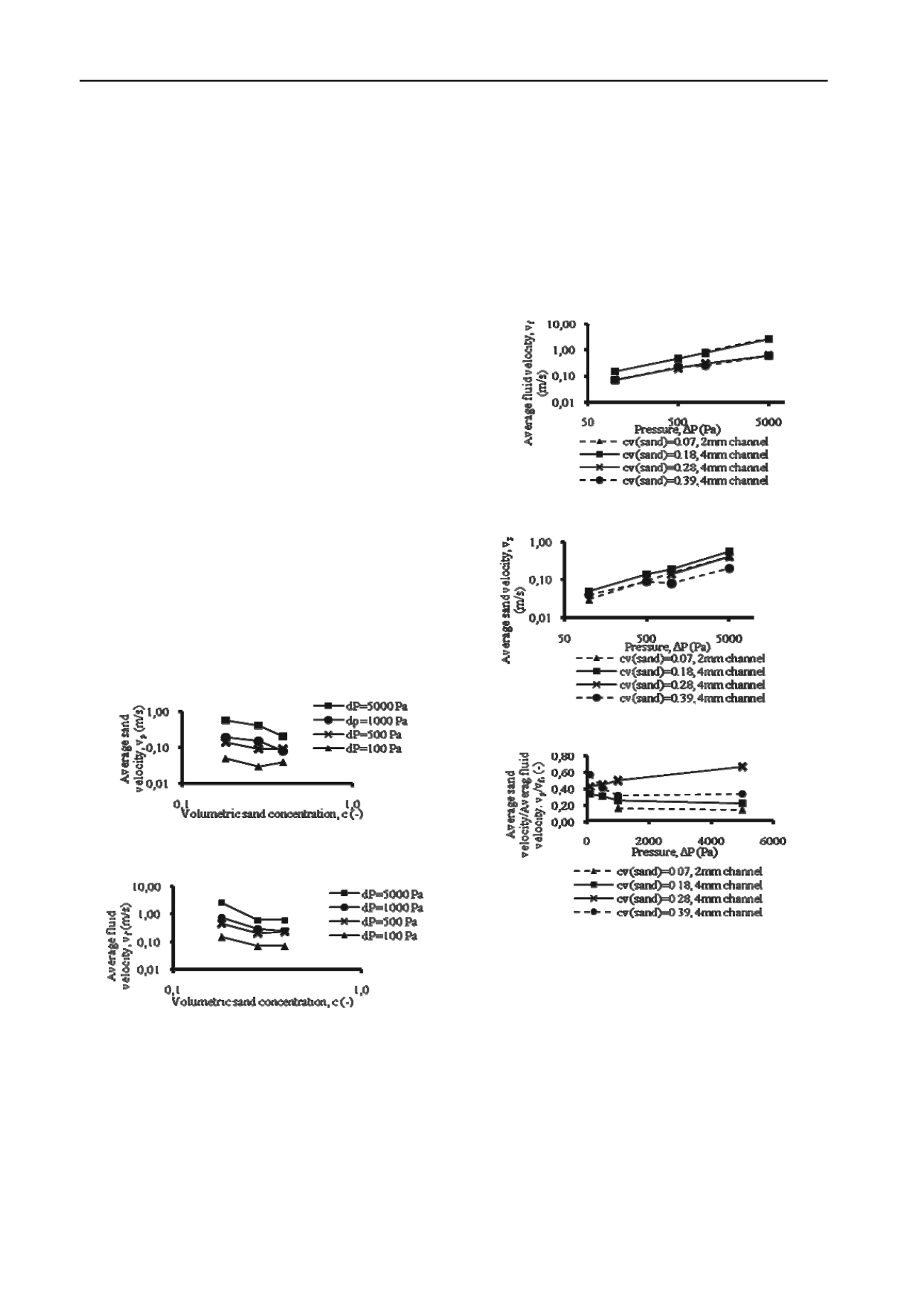

Fig. 5 shows the change of fluid velocity under different

presssure differences and sa

F

pressures

igure 4. Sand velocity dependence on concentration at different

Fig

(

c

ll the

observed cases had velocities low enough for the flow to be

considered laminar. (This can be seen in Figs. 6 and 7.)

ure 5. Sand velocity dependence on concentration at different

pressures

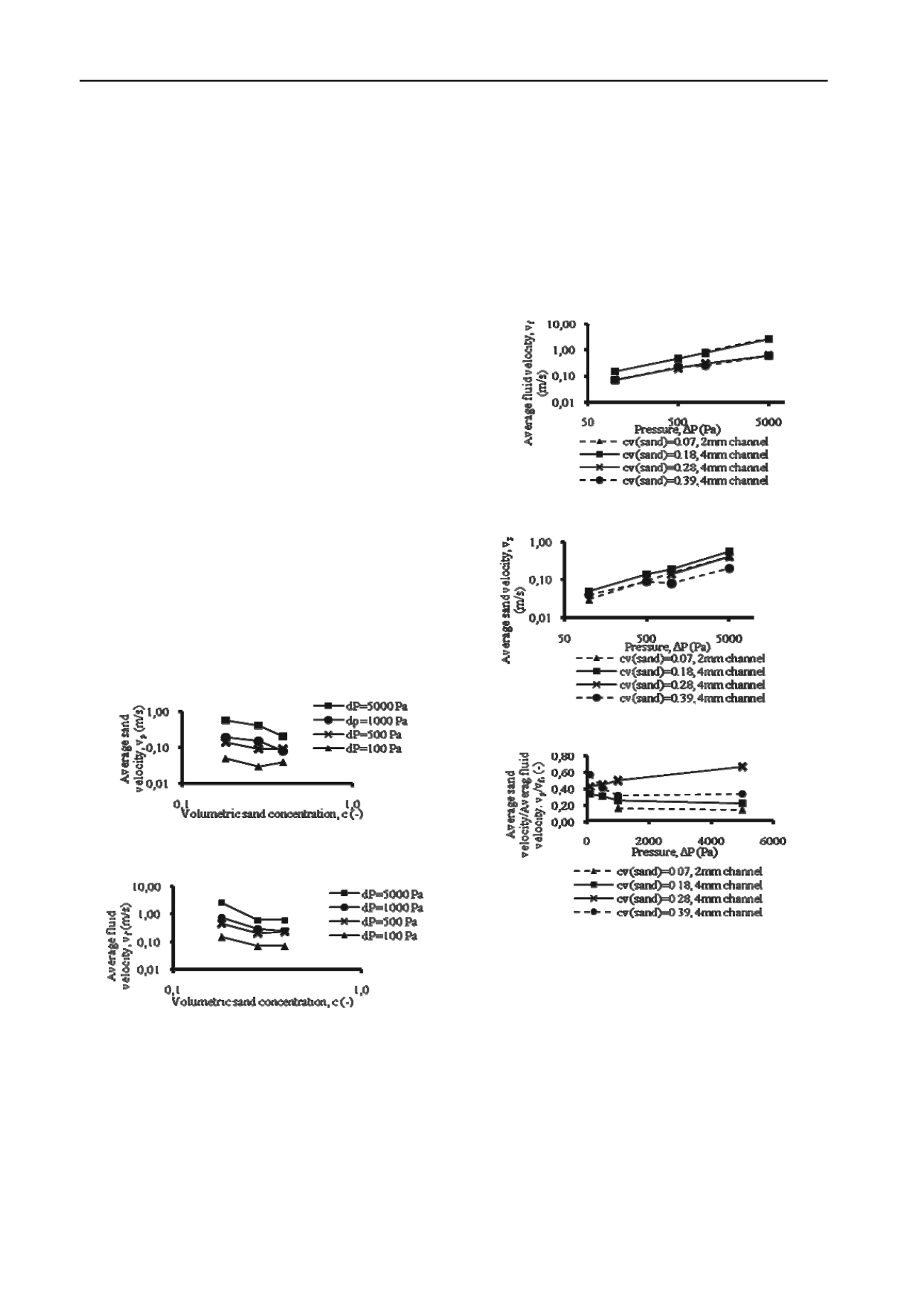

Figs. 6 and 7 indicate that both sand and fluid follow the

power-law dependence of velocity on sand concentration in log-

log plot. The velocity slopes in log-log plot are parallel and

increase with pressure decrease. However, if the sand velocity

and fluid velocity ratio is observed, it seems that it generally

rapidly decreases with pressure increase (Fig. 8) and then

approaches steady value at very high pressures. This behavior

can be related to stability of the flow and forming of particles

clumps that force fluid to flow arround them. When fluid flows

arround clumps, it flows in narrow channel and its velocity

localy inceases because of that. Pressure increase enhances the

frequency of particle collisions, whose damping causes

agglomeration. Results shown in Fig. 8 indicate, as well, that

velocities ratio depends on particles concentrations, not only on

channel pressure. For higher initial particles concentrations

v

=0.39) solids and fluid velocity ratio is more sensitive on

pressure change than for lower initial concentrations (

c

v

=0.18).

Higher sand concentrations obstruct the increase of fluid

phase flow velocity expected with pressure increase, as well as

sand phase velocity increase, while lower concentrations have

different impact on pressure dependent velocity. A

Figure 6. Average fluid velocity change with pressure

Figure 7. Average sand velocity change with pressure

igF

. 8) at a

given shear rate are investigated here with respect of fluid and

sand phase separately. Non-

ure 8. Average sand velocity and average fluid velocity ratio change

with pressure

Attempts were made in the past to describe the sand slurry

flow using the equivalent non-Newtonian parameters dependent

on fluid and particle phase characteristics, such as fluid

viscosity and sand volumetric concentration (Shah, 1993). The

proposed formulation was based on the assumption that fluid

and sand have the same velocities in the flow. However, here is

shown that this assumption is not valid for the narrow channel

and higher sand concentrations. The non-Newtonian parameters

K’

and

n’

that form apparent viscosity of the slurry (Eq

Newtonian fluid low is:

(8)

where

=shear stress,

=shear rate,

K

=non-Newtonian fluid

consistency index,

n

=non-Newtonian fluid flow-behavior index,

K K

1

'

n

n

n

a

K