3469

Technical Committee CFMS /

Comité technique CFMS

3

confining pressure (calculated using

= 0.70

and a

capillary stress of 3 kPa);

reference mean effective

confining pressure, 1 atm; and

slope of the

log

log

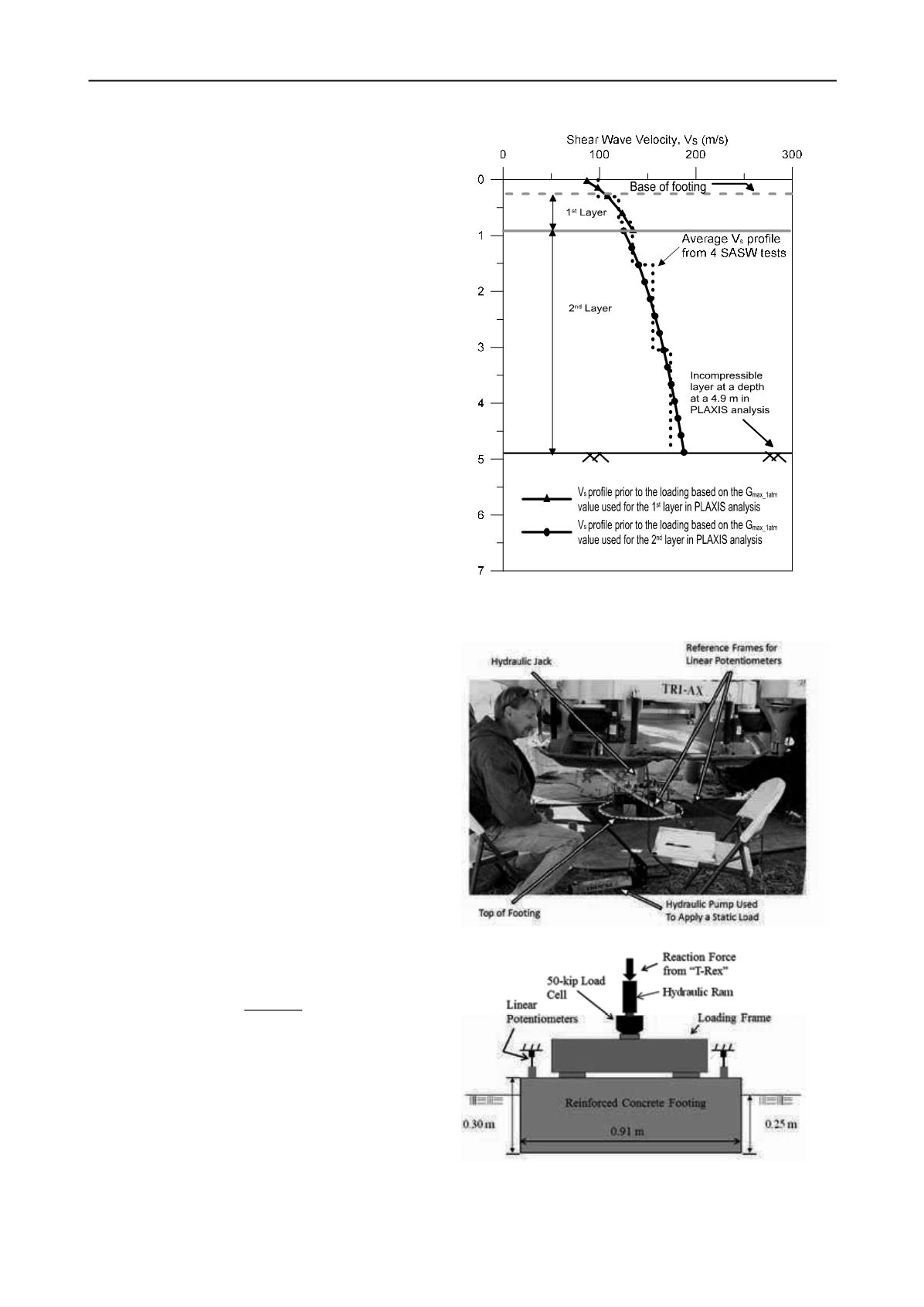

relationship. The modeling represented by

Equation 3 resulted in the two-layer profile presented in

Fi ure 2. The G

max_1atm

and n

G

parameters for each layer are:

layer 1 - G

max_1atm

= 86.2 MPa and 0.48; layer 2 - G

max_1atm

=

74.2 MPa and 0.51, respectively. The values of n

G

close to

0.5 indicate that the soil in each layer is uncemented.

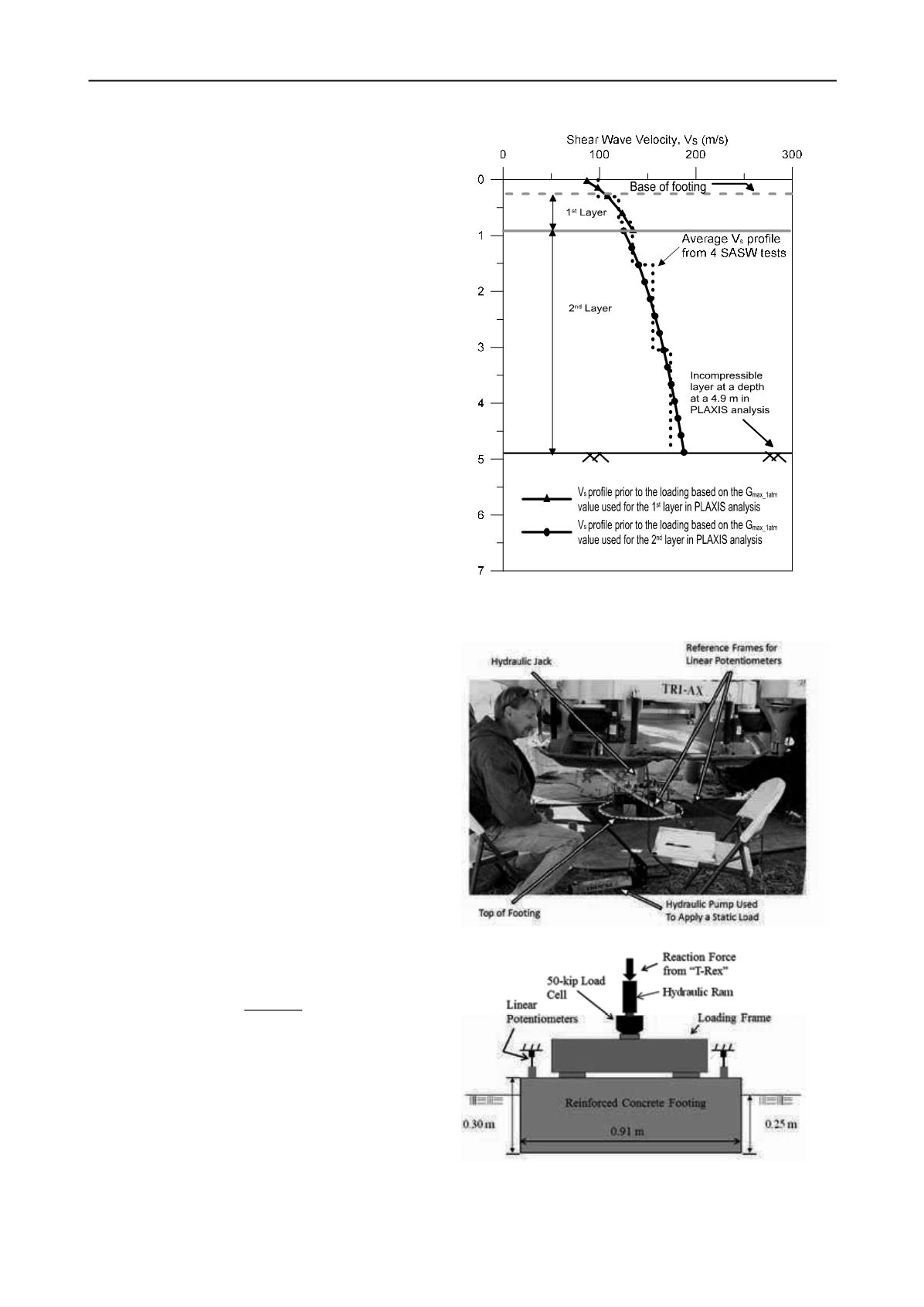

4.2.

Load-Settlement Test

A reinforced concrete footing with a diameter of 0.91 m and

a thickness of 0.30 m was constructed at the site after

removing the upper 0.25 m of soil. Linear potentiometers,

attached to a reference frame were used to measure footing

settlements. The load was applied by a hydraulic jack

reacting against the weight of a tri-axial vibroseis truck,

named T-Rex, as shown in Figure 3a. The load was

measured with a 50-kip load cell and was applied to the top

of the footing through a loading frame (see Figure 3b). The

load–settlement test was performed in March, 2010. The

measured load-settlement curve is presented in Figure 4 by

the solid line.

5 COMPARISON OF PREDICTED AND MEASURED

LOAD-SETTLEMENT CURVES

To investigate the settlement prediction methods, predicted

and measured load-settlement curves are compared. The

prediction methods are: (1) Schmertmann et al. (1978) CPT-

based method, (2) Burland and Burbidge (1985) SPT-based

method and (3) the method based on dynamic soil properties

presented herein. The predicted and measured load-

settlement curves are presented in Figure 4 and are discussed

below.

For the Schmertmann et al. method, the elastic moduli

were calculated based on the CPT results using:

2.5

(5)

where

modulus of elasticity of the soil; and

cone

penetrometer tip resistance. The upper 2 m of soil under the

footing was divided into 5 layers and an average value of

1.53 MPa of

was assigned to each layer. Additional

details on the procedure can be found in Van Pelt (2010). As

seen in Figure 4, the predicted load-settlement curve is not

as nonlinear as the measured curve, but predicts quite well in

the working-load range.

For the Burland and Burbidge (1985) method, settlements

are estimated using the SPT blow count, N

60

in the

correlation:

1.71

.

.

(6)

where

settlement (mm);

applied bearing pressure

(kPa);

footing diameter (m); and

average SPT

blow count over the depth of influence which is about 1 m

for a footing with B = 1m, uncorrected for overburden

pressure. As no SPT tests were performed at the field site,

the CPT tip resistance values were correlated to SPT blow

count using the correlations proposed by Robertson et al.

(1983). For an average

value of 1.53 MPa, this

correlation gives an average value of 5 for the SPT blow

count. As seen in Figure 4, the predicted load- settlement

Figure 2. Average V

s

profile from SASW tests and the two-layer

model used in the finite element analysis

(a)

(b)

Figure 3. Field Load-settlement test: (a) T-Rex in position during

loading (b) Cross-section of the load-settlement arrangement

Depth (m)