2195

Technical Committee 208 /

Comité technique 208

positive for reducing the rate of movement. The slope stability

analysis was considered only indicative due to the complex

nature of the sliding mass (fig 2) and greater emphasis was

placed on slope monitoring.

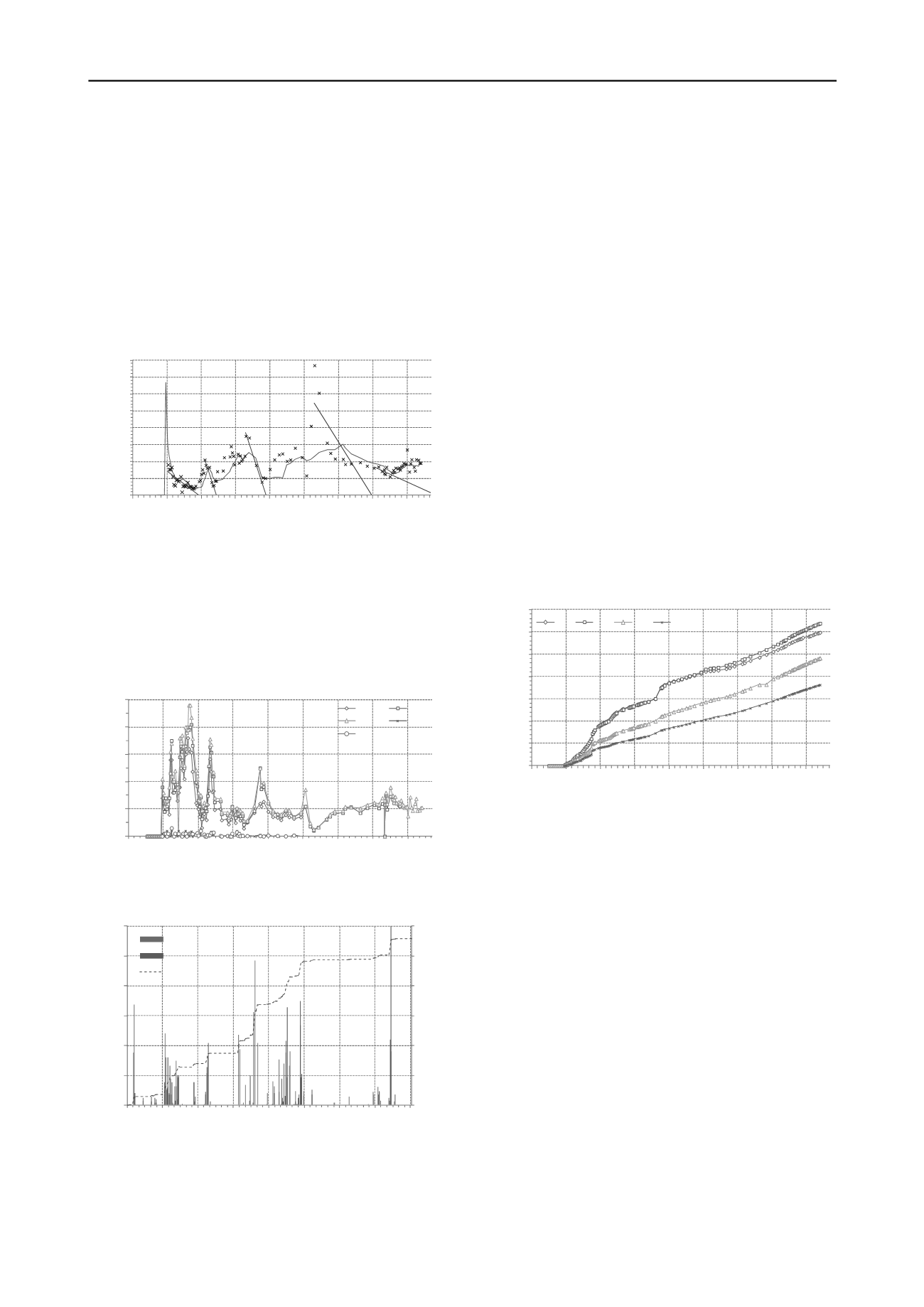

The data were further analyzed to verify the regressive type

of movement and to identify a possible onset of a progressive

type of movement, leading to failure. One method to evaluate

monitoring data is the inverse velocity measurement versus

time. Based on this method, as described by (Rose and Hungr,

2007), when the inverse velocity of slope movement is plotted

against time, failure is imminent as the trend line approaches

zero values (velocity increases asymptotically). In Figure 5 the

inverse velocity versus time is presented for prism 2A4.

0,00

0,05

0,10

0,15

0,20

0,25

0,30

0,35

0,40

01/01/12

31/01/12

01/03/12

31/03/12

30/04/12

30/05/12

29/06/12

29/07/12

28/08/12

Inverse Velocity (day/mm)

Date (days)

Figure 5. Inverse velocity versus time for prism 2A4

Figure 5 suggests that if this method is to be followed, at

numerous times the mine slopes could be at imminent collapse.

This is evaluated based on the extrapolation to zero of the

regression lines for different time intervals (straight lines). For

example the first imminent collapse could have been evaluated

to have occurred on 01/03/12, which did not happen.

0

10

20

30

40

50

01/01/12

31/01/12

01/03/12

31/03/12

30/04/12

30/05/12

29/06/12

29/07/12

28/08/12

Velocity (mm/day)

Date (days)

1A2

2A2

4A2

5A2

6A2

Figure 6. Velocity versus time for prisms of bench 2

0

50

100

150

200

250

300

0

5

10

15

20

25

30

1/1/2012

31/1/2012

1/3/2012

31/3/2012

30/4/2012

30/5/2012

29/6/2012

29/7/2012

28/8/2012

Cumulative Precipitation (mm)

Precipitation (mm)

Date (days)

LG26 (Pt)

LGS4 (NP)

Cumulative

Figure 7. Precipitation versus time from two stations

Subsequently regression analysis presented times that failure

could take place. This graph presents a situation where the

method could not work properly without evaluating other

critical factors such as precipitation or excavation unloading.

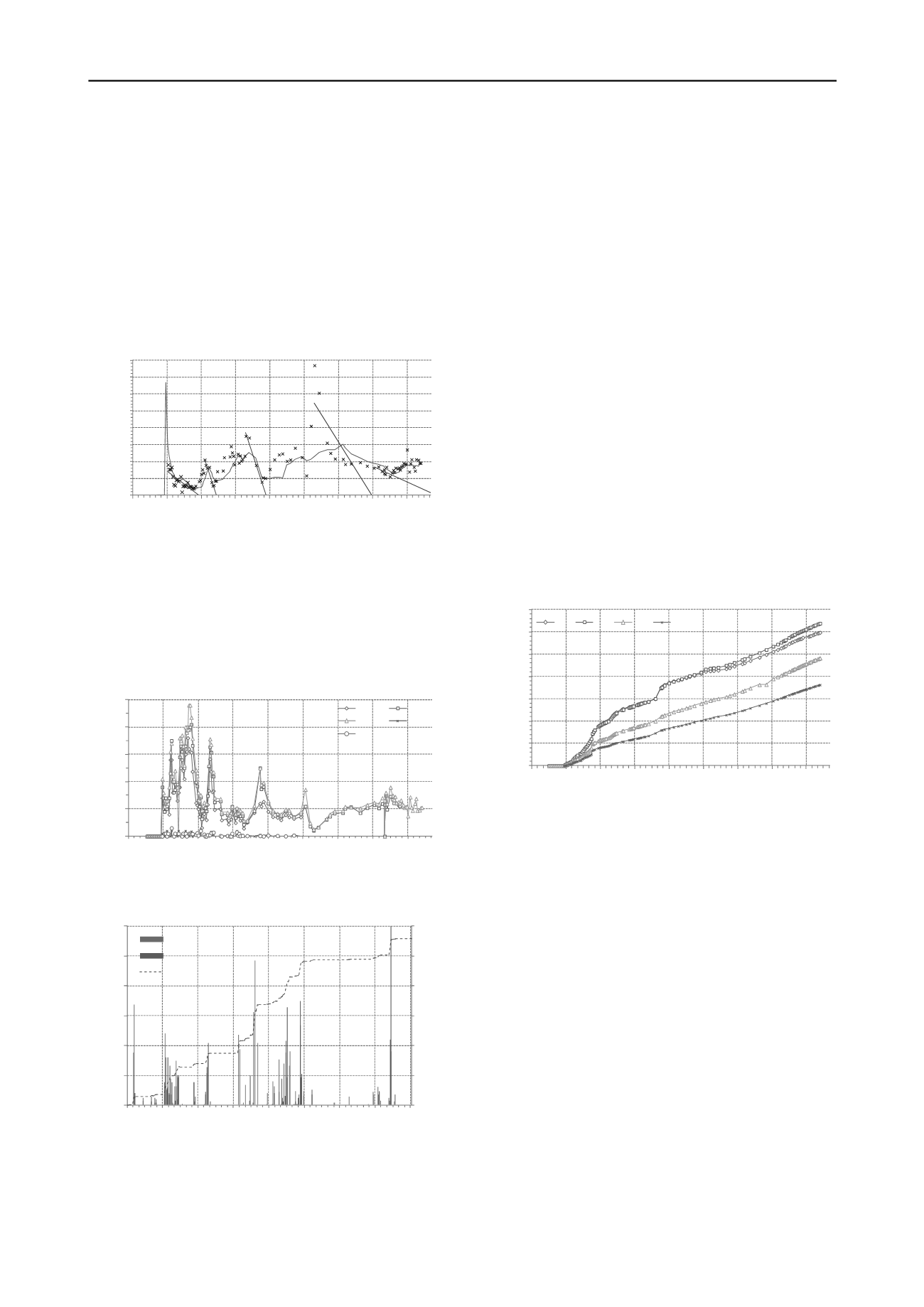

Figure 6 presents velocity versus time for all prisms of bench

2 while figure 7 shows the daily and cumulative precipitation

for two weather stations. The mine is located in between these

stations with a distance of about 7km. No precipitation data at

the mine were available.

From the evaluation of figures 6 and 7, a strong correlation

between the precipitation and the increase of velocity is

observed. Further observation of figure 6 provides information

of a stick – slip mechanism and a regressive type of movement

in which the velocity does not increase or decrease at a constant

rate but undergoes abrupt changes. During and after heavy

precipitation the water filled tension cracks provide an

increasing driving force. As displacement continues, the width

of the cracks increase and the water level drops with a

dissipation of water pressure. This is a repetitive situation which

modifies the velocity of the sliding mass. Beginning of

February 2012 limited (day shift) remedial excavation was

executed on bench 1 and above to reduce the weight of the

sliding mass. Such excavation increased after March 2012 being

conducted on 24hour shifts. As a result movement velocities

were reduced after that date.

In retrospect the movement was of the regression type (or

behaved in this respect due to the excavation at the top of the

slope) as can be seen from the displacement measurements at

bench 4 presented in Figure 8. In this graph the displacement at

the bench is plotted versus time for four different prisms in

different locations transversally placed on the slope (Figure 2).

0

500

1000

1500

2000

2500

3000

3500

01/01/12

31/01/12

01/03/12

31/03/12

30/04/12

30/05/12

29/06/12

29/07/12

28/08/12

Cumulative displacement (mm)

Date (days)

4A1

4A2

4A3

4A4

Figure 8. Cumulative displacement of prisms on bench 4

When the cumulative displacement becomes convex, movement

acceleration is evident and a progressive type of movement can

be inferred. When the cumulative displacement becomes

concave then deceleration takes place. As can be seen from

Figure 8 displacements “cyclically” change from convex to

concave and back to convex meaning that this is of a mixed

condition where the regressive type of movement prevails.

Although the cumulative displacement of this slope for a period

of 7 months is over 3m, the slope is still in a regressive type of

movement and therefore mine operations continue.

5 GEOMETRICAL MOVEMENT INFORMATION

The dense grid of monitoring prisms together with the high

accuracy of the robotic total station produced additional

invaluable data for the moving mass. As can be seen from

Figure 2 the vectors of motion are presented with arrows. The

continuous arrows present monitoring information until the

writing of this paper. The dashed arrows present monitoring

data that were discontinued for operational reasons at different

times. As can be seen from the arrows and the displacements at

bench 4 (figure 8) the slope moves more to the east than to the

west while both translation and rotation occurs at the same time.

The reason for this complex movement can be explained taking