2194

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

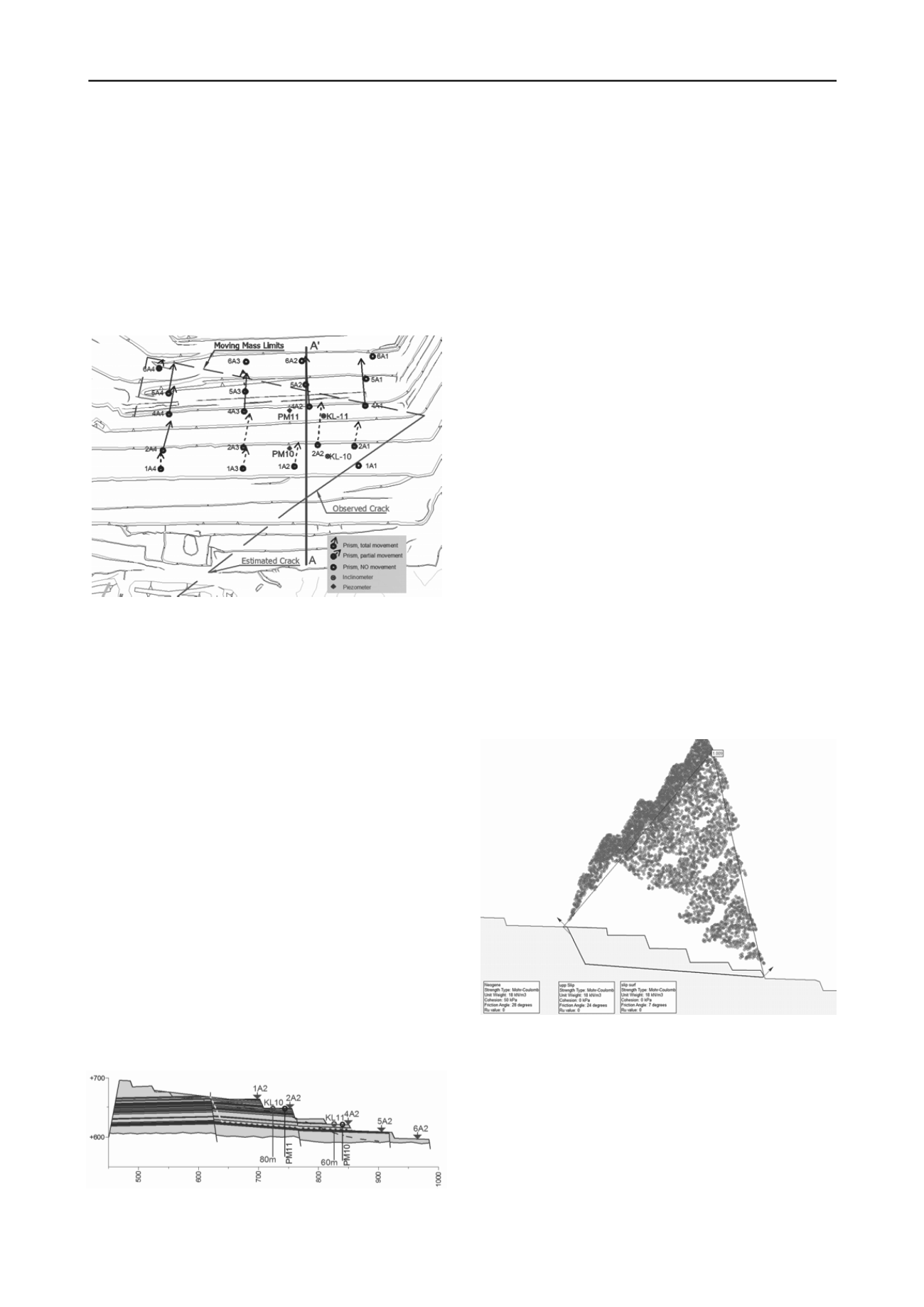

3 MONITORING OF SLOPE MOVEMENTS

At the end of 2010, tension cracks were observed at the crest of

the Southeast mine slopes and visually observed horizontal

transverse movements at the toe under prisms 5A3 and 6A4.

Although this is usual in large and deep open pit mines,

nevertheless, 20 prism monitoring stations, two inclinometers

(KL-10, 11) and two piezometers (PM-10, 11) were installed on

the slopes. The locations of the instruments are shown in Figure

2 together with the limits of the moving mass.

Prism measurement records were made available between

January 2012 and up to the writing of this paper (Sept. 2012).

Figure 2. Monitoring equipment and trends on Southeast slopes

Initially the measurements were executed with a lower accuracy

total station and only the “sloping distance” between the prism

and the measurement base was evaluated. Due to the complexity

and criticality of the situation, a new robotic total station of high

accuracy (0.5cc) replaced the old one. With the new total station

the movement vectors could easily be measured and evaluated.

The use of the robotic total station eliminated the surveyor

operation error and the high accuracy significantly reduced the

horizontal and vertical angular measurement error.

Due to the high rate of movement, few measurements were

taken from the inclinometers before they were sheared off.

From inclinometer KL-10, six measurements were obtained in a

period of one month which recorded a total displacement

100mm at 27m depth from ground surface. Inclinometer KL-11

recorded only three measurements in a period of 11 days, with

maximum displacement 150mm at 9m depth. The two

piezometers could only be measured twice due to operational

reasons and recorded water table elevation at 18.4m in PM-10

and 9.9m in PM-11. A precise water table could not be

estimated based on the piezometer measurements because of the

number of measurements and since the faces of the slopes were

found dry. Piezometric conditions and water pressures are very

difficult to model with a high degree of accuracy in mines

(Sullivan, 2007) mainly due to the presence of multiple perched

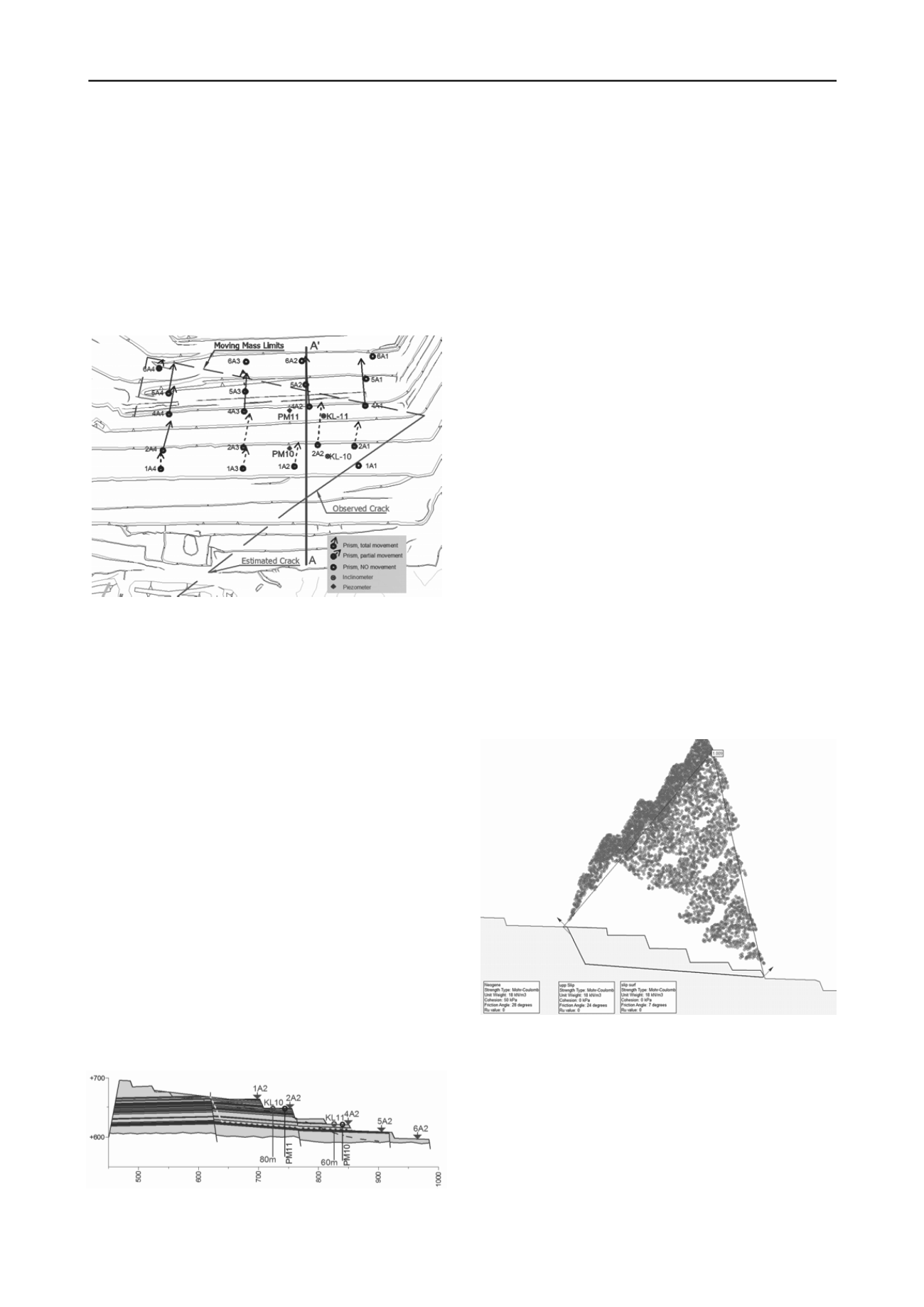

aquifers. Figure 3 shows a geological cross section with the

monitoring equipment and the failure surface location (white

line). Dark zones indicate the lignite beds.

Figure 3. A-A’ cross section with monitoring locations

4 EVALUATION OF SLOPE MOVEMENTS

The operation of Mavropigi mine is very important for the

power supply of Greece and uninterrupted operation is often

critical. Mining operations may take place even in moving

slopes, as long as safety of personnel and equipment is satisfied.

Zavodni (2000) states that “

mining operations can proceed

safely with minimum interruption if failure mechanisms are

understood and slopes are properly monitored

” even in moving

slopes. The way to assess if a “moving slope” can be mined

safely is to determine if the slope movement is regressive or

progressive. A regressive movement is cyclic decelerated while

a progressive movement exhibits overall acceleration without

appreciable deceleration intervals (Zavondi, 2000). In regressive

movements, mining operation can continue after incorporating a

monitoring system. If monitoring data indicate a progressive

type of movement the operations are in danger of imminent

collapse. The question posed to the Geotechnical Engineer is to

determine the type of movement that characterizes each

particular slope. The failure mechanism needs to be understood

and a sufficient quantity of qualitative measurements is

required. In the literature, most case studies are analyzed after

an incident and with adequate monitoring data and the type of

movement is identified (Ryan & Call 1992). At the Mavropigi

mine, decisions had to be made based on the day to day data

becoming available without a priori having a large amount of

data that could be used to determine the type of movement.

Initially, based on the geological model of the area, the

visual observations of the cracks in the crest and the

translational surface located by the inclinometers, a limit

equilibrium model was analyzed to evaluate if the movement

was possible and to back calculate the material properties of the

shear surface. Based on back analysis (Figure 4) it was found

that a sliding surface was possible with residual friction angle of

φ

r

=7

o

for the near horizontal surface and φ’=24

ο

for the back

scarp. These values were considered to be the lower bounds

since no water pressures were introduced and were in good

agreement with the laboratory ones provided in Table 1 for the

area.

Figure 4. Back analysis of the sliding surface

From the geological model, the inclinometer readings and the

back analysis it was found that the movement is taking place in

a failure shear zone (thin high plasticity clay interlayer) with an

inclination of about 4-5

o

. Based on this information an initial

estimate was made that the movement could be of the regressive

type based on the recommendations by (Zavodi and Broadbent,

1980), by which movements are deemed regressive when taking

place on a surface with a lower angle in relation to the slope

face inclination and the shear resistance (friction angle) of the

material. Initial remediation measures consisting of excavating

part of the top two benches were analyzed with the same data.

Analysis showed that the FS became 1.06 which was considered