2179

Technical Committee 208 /

Comité technique 208

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

model the sensitive clay using Eq. 2 are also shown in Table 1.

These parameters are estimated based on the laboratory tests

conducted on sensitive clays (e.g. Tavenas et al., 1983) and the

interpretation of test data and constitutive model development

by other researchers (e.g. Bernander 2000, Leroueil 2001,

Locat et al. 2008, Quinn 2009, Locat et al. 2011).

4. FINITE ELEMENT RESULTS

4.1

Propagation of shear band

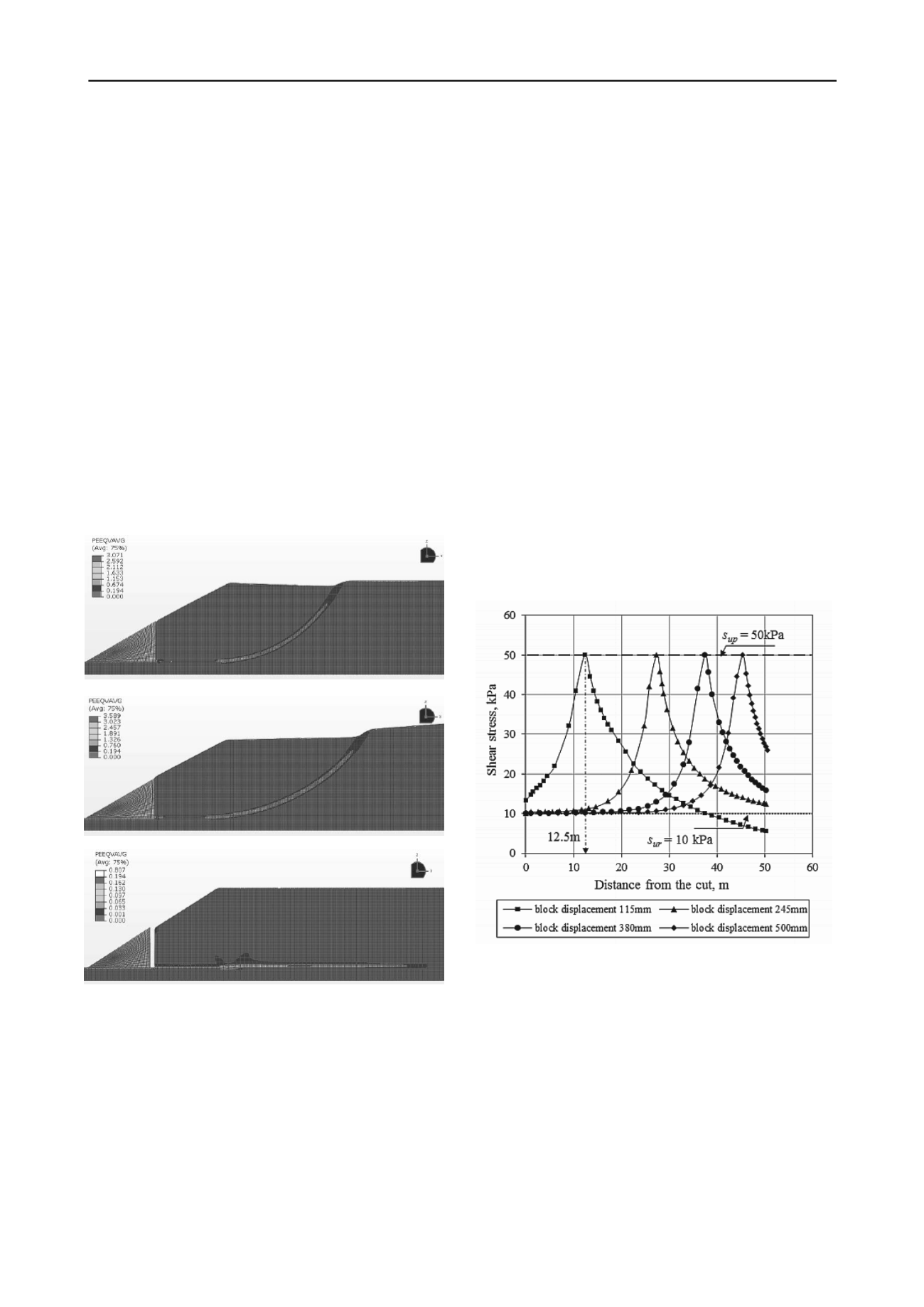

Figure 2 shows the variation of equivalent plastic shear strain

for three cases. In Cases-I & II the shear band initially

propagates horizontally and then curved upward resulting in

global failure. The failed soil mass follows the

excavated/eroded soil block. Figures 2(a) & 2(b) show the

equivalent plastic shear strain when the plastic shear strain in

the entire failure plane is greater than γ

p

95

. Global failure does

not occur in Case-III (Fig. 2c). There is an approximately 1.4 m

gap between the vertical face of the block and soil mass at the

right. The shear band propagates horizontally and finally ended

at certain length. Figure 2(c) also shows the plastic shear strain

when the shear band propagation is ended. Whether the shear

Figure 2. Developed equivalent plastic strain in the softening layer in

case I, II and III respectively

band will propagate upward and cause the global failure or not,

depends on the shear strength of the upper soil layer and

mobilized shear strength along the shear band. For the soil

properties and geometry used in the present study the failure

pattern is almost same for Cases-I and II. However, the released

energy from the excavated/eroded soil block is not sufficient to

move the shear band upward in Case-III to cause the failure of

the slope.

The equivalent plastic shear strain, denoted by the symbol

PEEQVAVG in Fig. 2, is related to γ

p

as PEEQVAVG= γ

p

/ .

According to Eq. (2), when γ

p

γ

p

95

(=33%), that means

PEEQVAVG=0.194, the undrained shear strength is less than

12 kPa (=50-0.95(50-10)). Figure 2(c) shows that the equivalent

plastic shear strain greater than 0.194 is developed in the shear

band only near the vertical face of excavated/eroded block in

Case-III. However, the equivalent plastic shear strain greater

than 0.194 is developed in the entire length of the failure plane

in Case-I & Case-II. Therefore, the failure of the slope is

occurred in both cases at residual shear strength on the failure

plane as large strain is developed.

4.2

Shear stress and mobilized shear strength

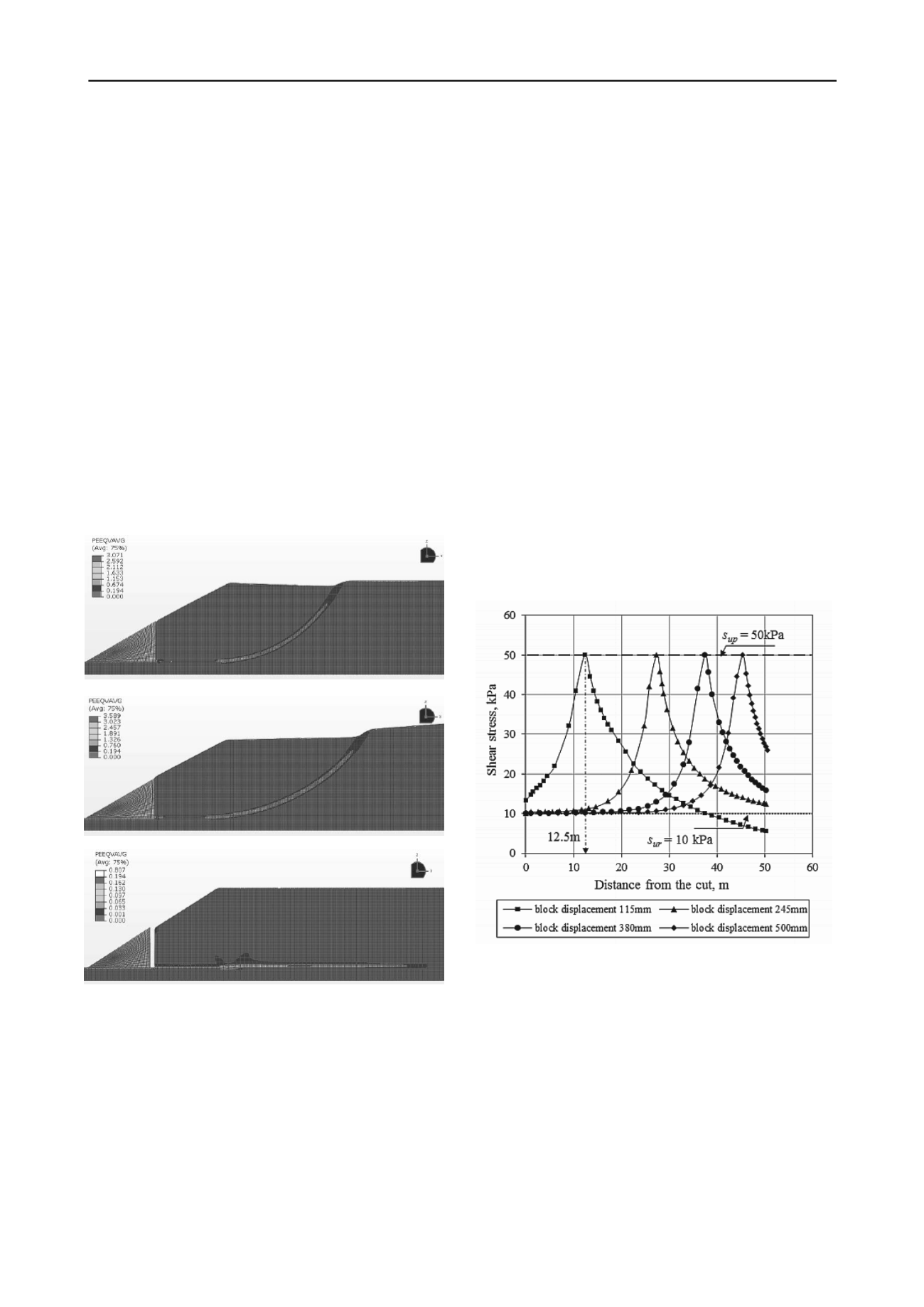

The Case-III is considered for further examination of the

development of shear stress and mobilized shear strength along

the potential failure plane. Figure 3 shows the variation of shear

stress along the failure plane with movement of

excavated/eroded block. Shear stress for four displacements

(115 mm, 245 mm, 380 mm and 500 mm) are shown. In order

to explain the process, consider the shear stress on the potential

failure plane for the block displacement of 115 mm. The

maximum shear stress (50 kPa) is developed at 12.5 m from the

vertical face of the cut. The shear stress between 0 to 12.5 m is

less than 50 kPa (i.e. s

up

) and greater than 10 kPa (i.e. s

ur

). That

means, 0-12.5 m of the shear band represents the post-peak

softening zone where the reduction of shear strength is occurred

because of plastic strain as Eq. 2, and the mobilized shear

strength is in between the peak and residual shear strength of

the soil. In the right side of the peak (i.e. distance greater than

12.5 m) the shear stress is again reduced with distance. For this

displacement of the block (115 mm), the shear stress in the

Figure 3. Shear stress along the potential failure plane

potential failure plane at a distance greater than 12.5 m is not

increased to the peak, and therefore it represents the pre-peak

behavior. At a very large distance, the shear stress is reduced to

zero in Case-III as the ground surface is horizontal. The pattern

of shear stress development for any other displacement of the

block is similar as shown in Fig. 3. The location of the peak

shear stress shifts to the right with increase in block

displacement; that means a greater length of the potential failure

plane is in post-peak stress-strain condition. For example, for

500 mm block movement the peak is occurred at 45.5 m and

therefore 0-45.5 m is in post-peak condition with approximately

30 m in residual shear strength level. This process will be

continued until the shear band propagation is ended for stable

slopes as in Case-III. However, if the failure is occurred, as in

Case-I and II, the large plastic shear strain will reduce the shear