1940

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

1 Geological

mapping.

Over 0.75 Sq.Km on 1:1000 scale.

2 Core drilling Double tube barrel

–

over 3000 m

Triple tube barrel

–

over 500 m

3 Trenches

Three parallel trenches of +30 m.

Six cross trenches of + 15 m

4 Shafts

Six shafts of 9.5 to 18m depth, 3.5

m dia.

5 Drifts

Four drifts of +16

–

23 m.

6 Bore hole

camera studies

In 2 drill holes to study cavitations

in silt stone/bedding shear zones.

This Data indicated that the sheared /crusted rock mass shall

get consolidated if consolidation grouting is carried out and

after completion of coffer dam, curtain grouting is also

recommended, 1 m from the u/s face of coffer dam. Both these

treatments were absolutely necessary in view of typical

geotechnical problem faced. These treatments were carried out.

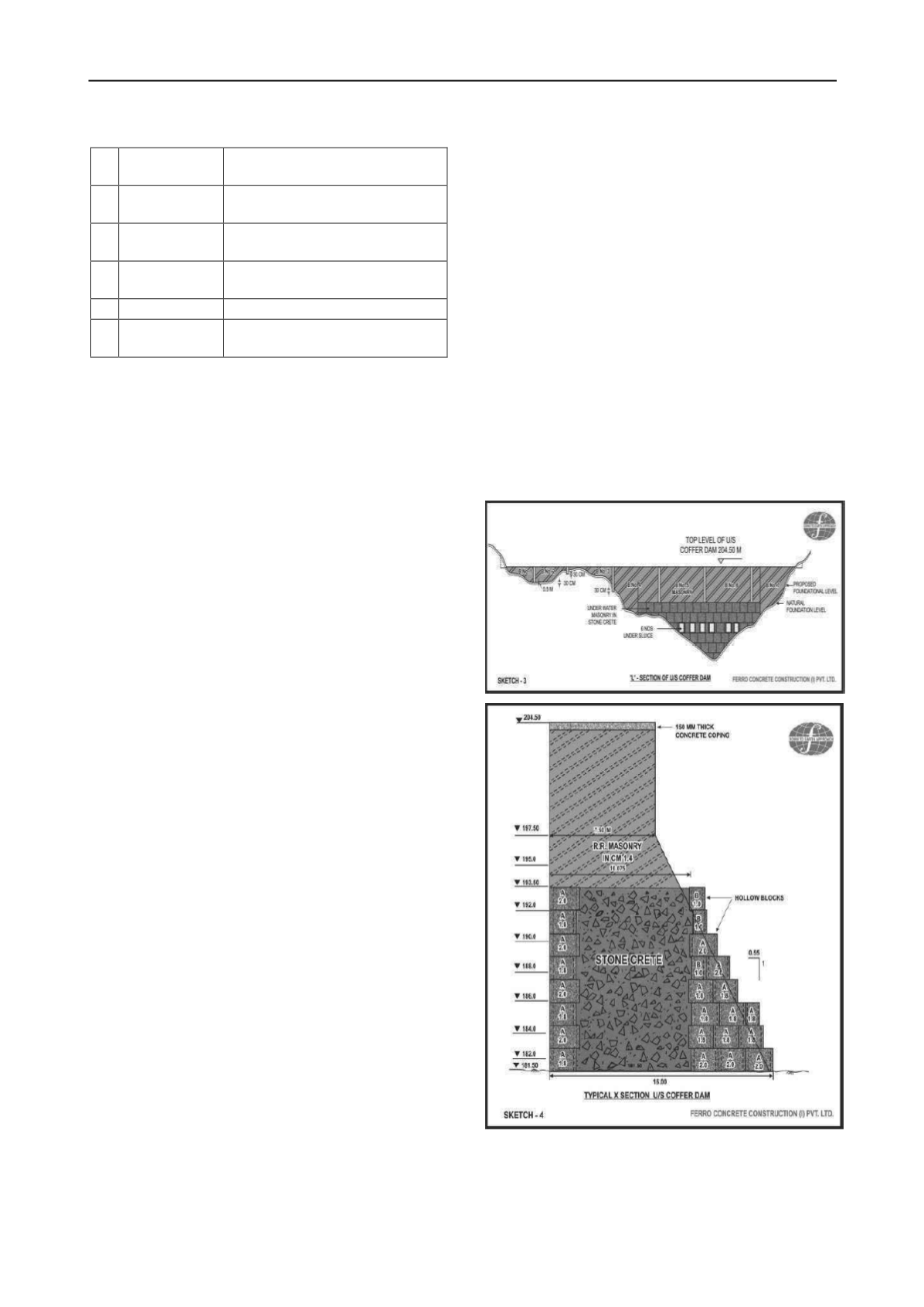

3. COFFER DAM - UPSTREAM AND DOWNSTREAM

The u/s coffer dam was necessitated to stop and divert the post

monsoon river flow, to facilitate construction of main dam.

This post monsoon flow ranging from 300 cumecs to 100

cumecs was required to be diverted from a diversion tunnel

which was under construction through the left abutment.

As the construction of diversion tunnel was getting delayed

considerably, provision of six sluices in the body of u/s coffer

dam was envisaged to pass the post monsoon flow.

3.1 Concept.

The work consists of design and construction of upstream and

downstream coffer dam of Indira Sagar Project. This was the

new concept of design used for first time in any country to

construct a coffer dam using 5 tons pre-cast blocks as

shuttering on both faces u/s and d/s side of a dam, and filling

the enclosure with boulders and stonecrete them under water.

All work of coffer dam has been done underground and under

water upto RL 193.5 m.

The maximum height of u/s coffer dam was 24 meter, 12 m

under water and 12 m above water. The lowest foundation

level in river bed was ± 180.60 m. For under water portion 5

ton hollow pre-cast c.c. blocks were casted and placed on the

u/s and d/s face of dam, as a shuttering in a cell of 15 m length

with the help of divers. Before placing the blocks, river bed

was leveled by using blasting under water and with special

technique, PC blocks were placed. Boulders were filled in the

enclosure of a 15 m long cell and grout pipe with safety

reinforcement were placed. The cell of 15 m was thoroughly

caulked from outside, so that river flow does not have any

effect in the cell. A colloidal grout, made out of sand, cement

water and super plasticiser was pumped through the grout pipe

at bottom and level of grout slowly built up from down upward.

Thus colloidal grout (colcrete) replacing the water in the voids

of the boulder and converting the boulder mass into concrete.

This under water work was carried out upto 193.50 m level.

About six pre-fabricated construction sluices of 2 m x 3 m were

placed to take care of post monsoon discharges upto 300

cumecs as the diversion tunnel was under construction and was

not ready.

Stone masonry was constructed above water level over the

underwater works from RL 193.5 m and raised upto RL

204.50 m.

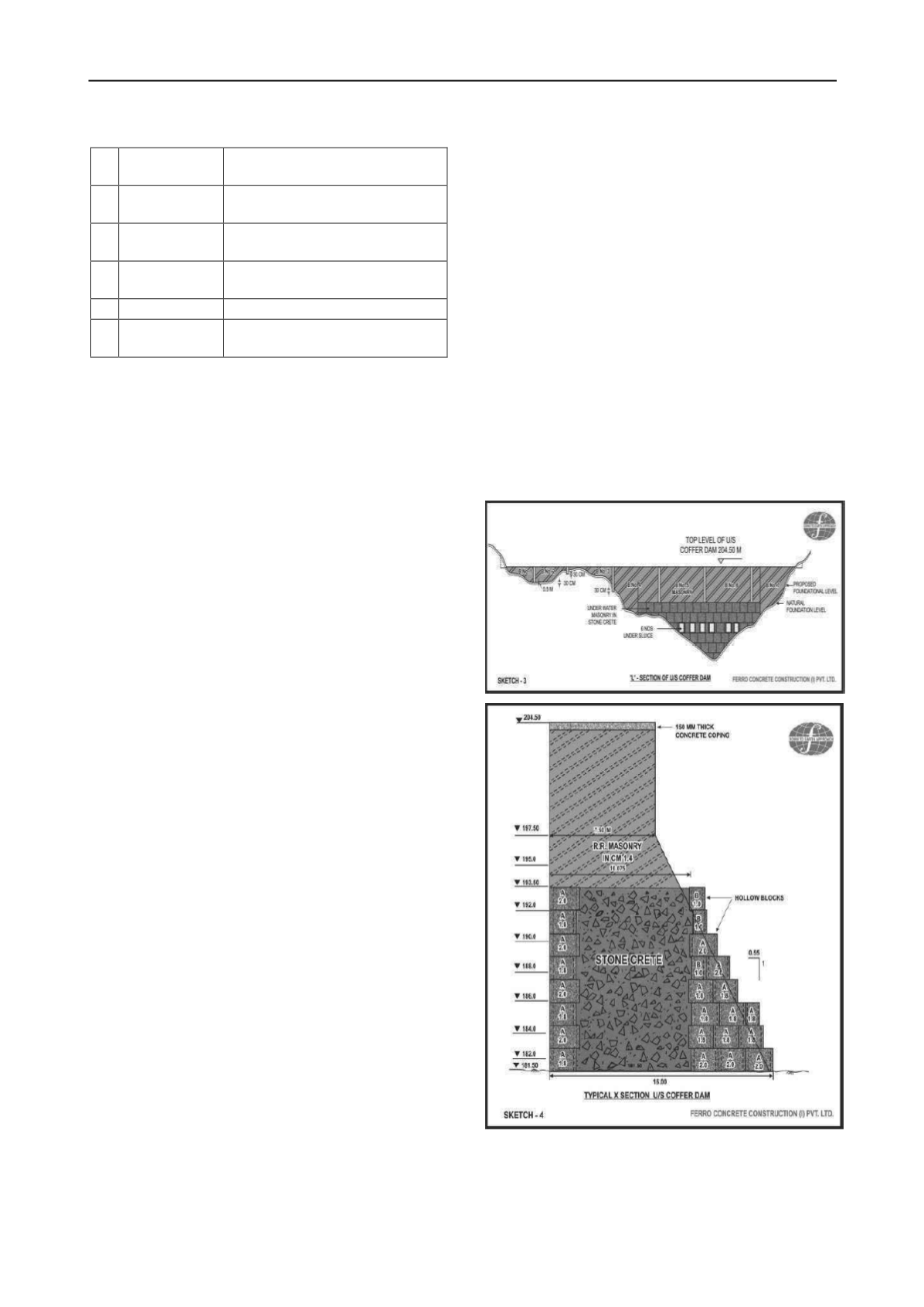

3.2 Design.

Height of u/s coffer dam was 24 m with the lowest foundation

level kept at 180.6 and top of coffer dam as RL 204.5m. It has

been designed on the principle of gravity dam, duly checked,

for stability in various condition like Reservoir empty and

Reservoir full etc. with following parameters :-

3.2.1 Coffer dam:

a) Above water level, Randam rubble masonry with a

compressive strength of 10.5 N/mm2 (cement mortar 1:4

approximate) with selected stone placed in u/s and d/s face.

b) Under water stonecrete masonry in 1:2 and 1:3 colcrete with

P.C.C. Blocks on u/s & d/s faces.

c) PCC blocks in M-15 grade Concrete.

d) Coping : Concrete of M20 grade (c.c. 1:1.5:3) with 20 mm

graded metal.

It may be observed that for underwater work, PCC blocks were

kept on u/s and d/s section of the coffer dam and they were

considered as a homogenous part of the full section. Dam cross

section and L-section can be seen vide sketch

–

3 and 4.