1924

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

reinforced fill and had to be cut and anchored in order to widen

the roadway.

Therefore, this layer was fully investigated with:

Several SPT borings.

Laboratory tests: direct shear and expansion tests on

undisturbed samples and characterization.

Pullout tests on anchors.

Moreover, compaction and direct shear tests were carried out on

fill materials.

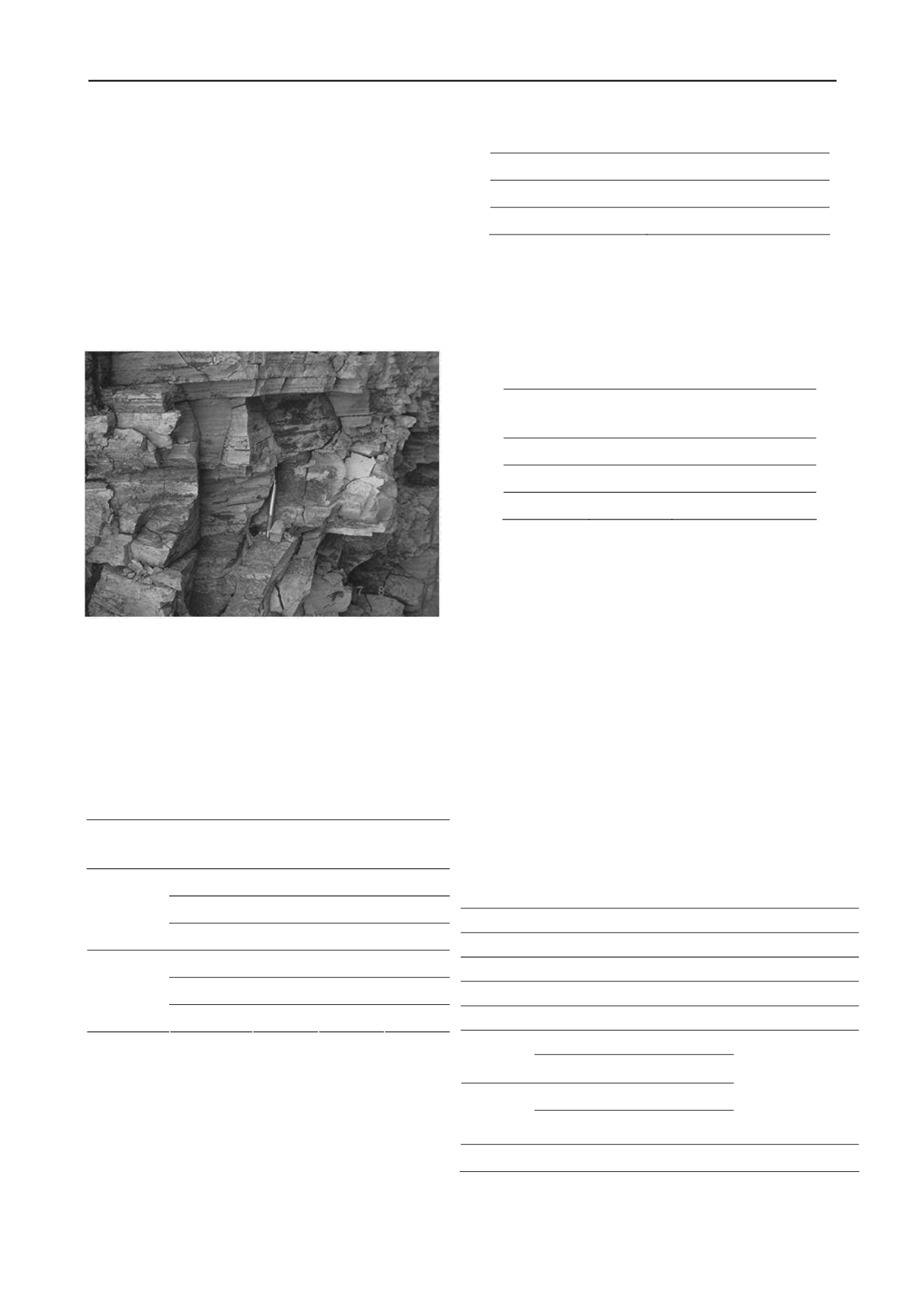

Figure 2. Stiff to hard silty clay layer to be cut and retained with

anchored wall and surcharged with reinforced soil fill.

3 TEST RESULTS – STIFF TO HARD CLAY

Table 1 presents results from direct shear tests. It is worth

noting the large drop in shear strength for large displacements

(residual conditions). Peak strength typically occurs for very

small displacements, in the range of 1mm.

Table 1. Direct shear test results.

Sample

Specimen

(kPa)

máx

(kPa)

res

(kPa)

CP-1

51

232

32

CP-2

154

305

22

Natural

CP-3

306

419

92

CP-1

51

228

77

CP-2

151

264

72

Saturated

CP-3

304

304

34

Table 2 presents results from expansion tests carried out on the

horizontal and vertical directions. The expansion pressure is

very high in the vertical direction, whereas the expansion

pressure in the horizontal direction is around 6% of the vertical

pressure, showing the marked influence of clay structure on its

behavior (Figure 2).

Table 2. Expansion pressure for vertical and horizontal directions.

Direction

Expansion Pressure (kPa)

Vertical

440

Horizontal

30

Table 3 presents results from pullout tests on anchors 10cm in

diameter and 6m long as a function of injection pressure.

Anchors 202, 207 and 212 had, respectively, one, three and two

functioning pressure valves. Therefore, adhesion values varied

significantly from 25 to 45kN/m, demonstrating marked

influence of injection pressure on adhesion.

Table 3. Pullout tests on anchors.

Segment

Adhesion

(kN/m)

Injection Pressure

(kgf/cm²)

202

25

(1 valve)

207

45

50/20/30 (3 valves)

212

30

(2 valves)

4 DESIGN PARAMETERS

The following design conditions and strenght parameters were

considered for design:

End-of-Construction (EOC): peak shear strength parameters

and natural water content, with and without expansion

pressure.

Long-Therm and Peak Condition (LTP): saturated peak shear

strength parameters, with and without expansion pressure.

Long-Therm and Residual Condition (LTR): saturated

residual shear strength parameters, with expansion pressure.

A possible decrease in adhesion due to soil saturation was also

considered in adhesion. Increase in anchor loads due to

expansion pressure was taken into account for anchor design.

With basis on the laboratory and field tests, and following

the procedures outlined in ABNT NBR 11.682 – Slope

Stability, the parameters presented in Table 5 were used in wall

design.

Table 5 – Design parameters.

Condition/

Parameter

EOC

LTP

LTR MSE*

Soil unit weight (kN/m³)

20

20

20

20

Cohesion intercept (kPa)

60

40

0

30

Friction angle (º)

30

18

18

25

Average

100

90

Anchor

adhesion

(kPa)

Maximum

140

125

Average

70

65

Same with

expansion

(kPa)

Maximum

100

90

125

Puncture anchor head (kN)

430

-

*MSE :Soil Parameters for Mechanically Estabilized Earth Wall