1925

Technical Committee 207 /

Comité technique 207

5 DESIGN AND CONSTRUCTION OF ANCHORED

WALL

6 WALL MONITORING

A limit equilibrium program was used to design the

anchored wall, considering the reinforced wall on the top and a

traffic surcharge of 25kPa. Potential failure surfaces were

always very close to the anchored wall face. As a result, the free

section of the anchors were short, in the order of 3.0m. This is

the minimum length accepted by ABNT NBR 5629 – Anchored

Walls. Anchor length was varied in order to achieve minimum

Safety Factor of 1.8 for EOC, 1.5 for LTP, and 1.2 for LTR

conditions, resulting the following anchor distribution:

In order to monitor wall behavior a monitoring system was

installed along the wall. It consisted of:

3 inclinometers 15m deep installed

3 load cells installed at selected anchor heads

20 displacement pins

Inclinometers were installed in boreholes along the front face of

the anchored wall, and extended upwards during placement of

the reinforced fill.

Several readings were obtained during construction of the lower

anchored section and continued durgin construction of the upper

reinforced fill section.

Cable anchors, 5x12,7mm 190RB, yield stress= 1708MPa

Working load = 430kN

Testing load = 760kN

Minimum spacing = 1,6m

7 MONITORING RESULTS

Maximum spacing = 2,0m

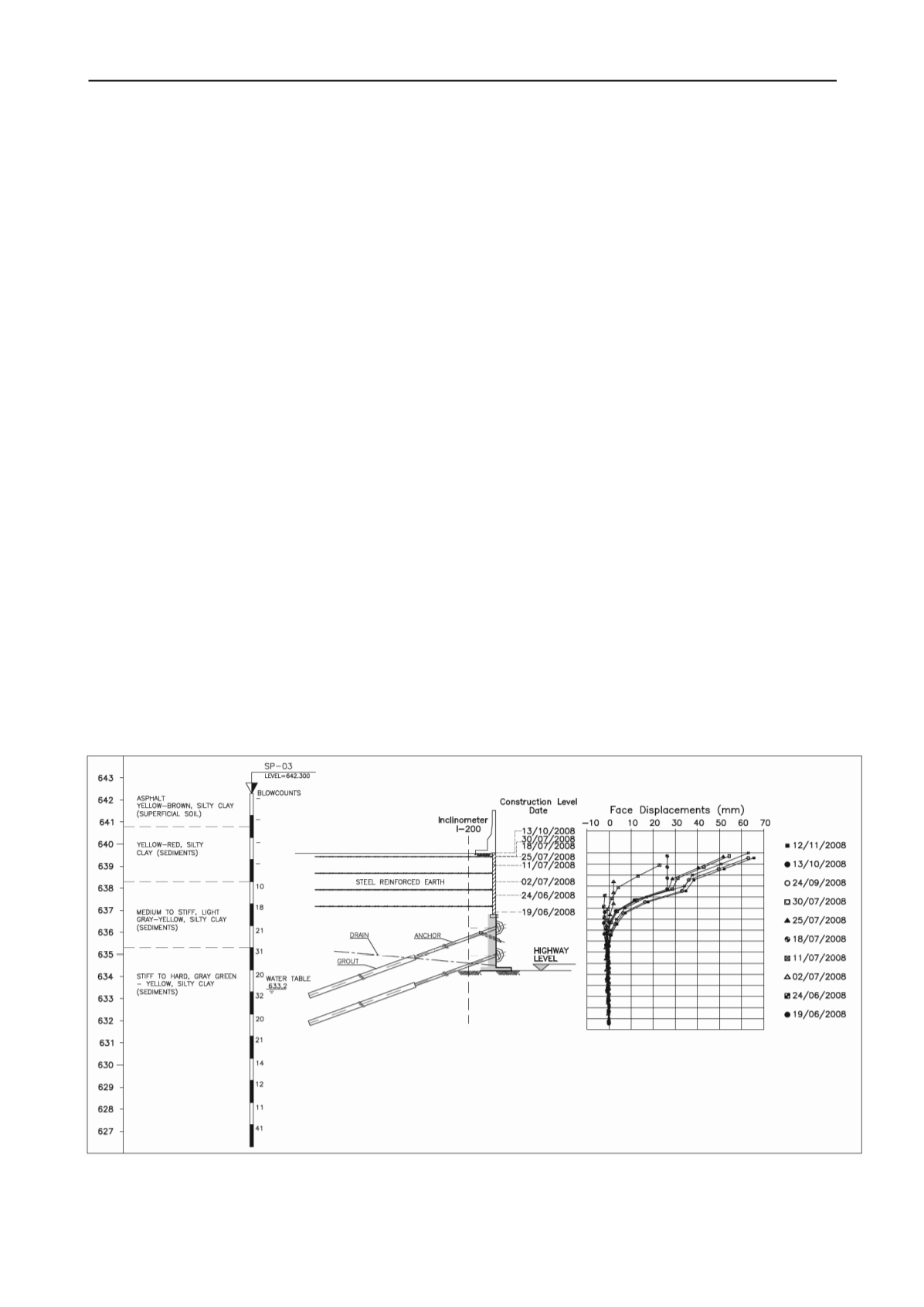

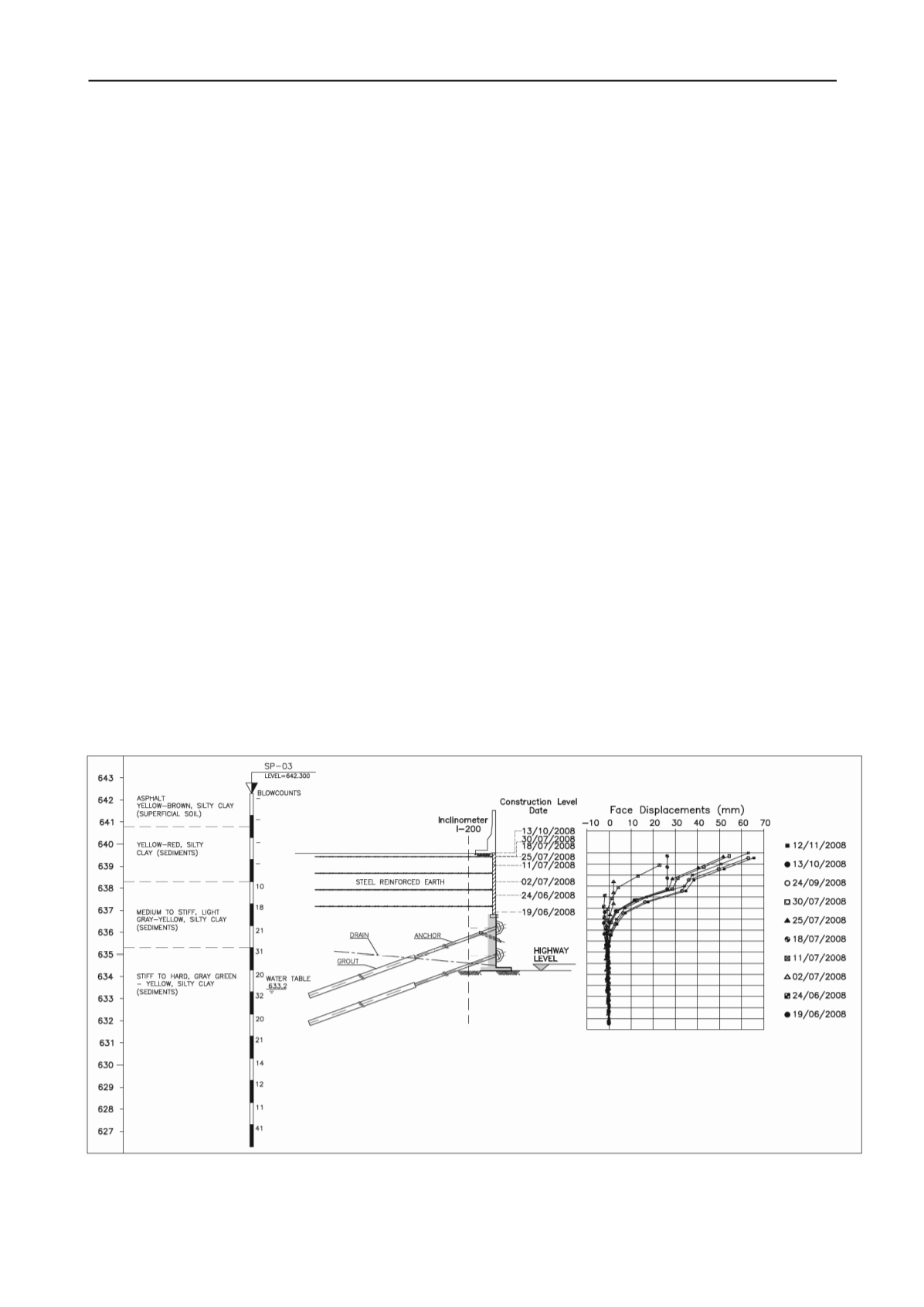

Figures 3 and 4 show inclinometers results for 2 of the

instrumented sections: Section I-200 and Section I-205. The

results show that:

Inclination with horizontal = 20 degrees

Free length = 3,0m

Anchored length = varying from 6.0 to 9.0m

Anchor diameter = 100mm

Water table close to the base of the anchored wall was found

in several SPT bores. Therefore, horizontal drains 15m long

were installed every 2.4m along the wall base.

The displacements increase continuously with construction of

the lower anchored wall and the upper reinforced soil wall.

Displacements of the lower anchored wall were generally

small, in the range of 5 to 10mm.

The stiff clay layer was carefully excavated to install the

anchors and build the reinforced concrete face 30cm thick. For

each anchor level the anchors were loaded to 50% of the

working load. Construction of the reinforcef fill started after the

completion of the anchored wall. When the reinforced fill height

reachedd around 70% of the final fill height the anchors were

re-loaded with 100% of the final working load.

Small face displacementes were expected for the stiff clay

layer. However, for these displacements level it is possible

that residual conditions may be attained by the clay layer

during wall construction.

For the upper reinforced fill, however, face displacements

were relatively high. Measured displacements varied from

around 10mm at the bottom up to 70 to 80mm for the upper

part of the fill.

Figure 3. Inclinometer results in Section I-200.