917

Technical Committee 104 /

Comité technique 104

5.1

Consolidation

The first step in the centrifuge model test is to reconsolidate the

clay model in-flight at an acceleration of 50 g, due to the

increase in self-weight. Dissipation of the excess pore water

pressures took approximately 13 h (Fig. 4).

5.2

Stone column installation

The stone column installation tool developed by Weber (Fig. 5;

Weber, 2008) has been used to construct the stone column. It

consists of a steel tube with an outer diameter of 10 mm and an

inner diameter of 8 mm. A drawing pin was used to prevent the

tube from blocking during first penetration.

Fig. 5: Stone column installation tool (Weber, 2008).

The column tool was inserted up to a depth of 120 mm in the

centre of the clay model and the column was built with a 15/10

compaction regime (i.e. once the desired installation depth was

reached, the tool was extracted by 15 mm before being inserted

again 10 mm, compacting the sand in the column). This

compaction process increases the stone column diameter to 12

mm (see Fig. 1), at least in the softest clay layer near the

surface. The insertion was displacement-controlled (2 mm/s)

and the driving force as well as the pore water pressures were

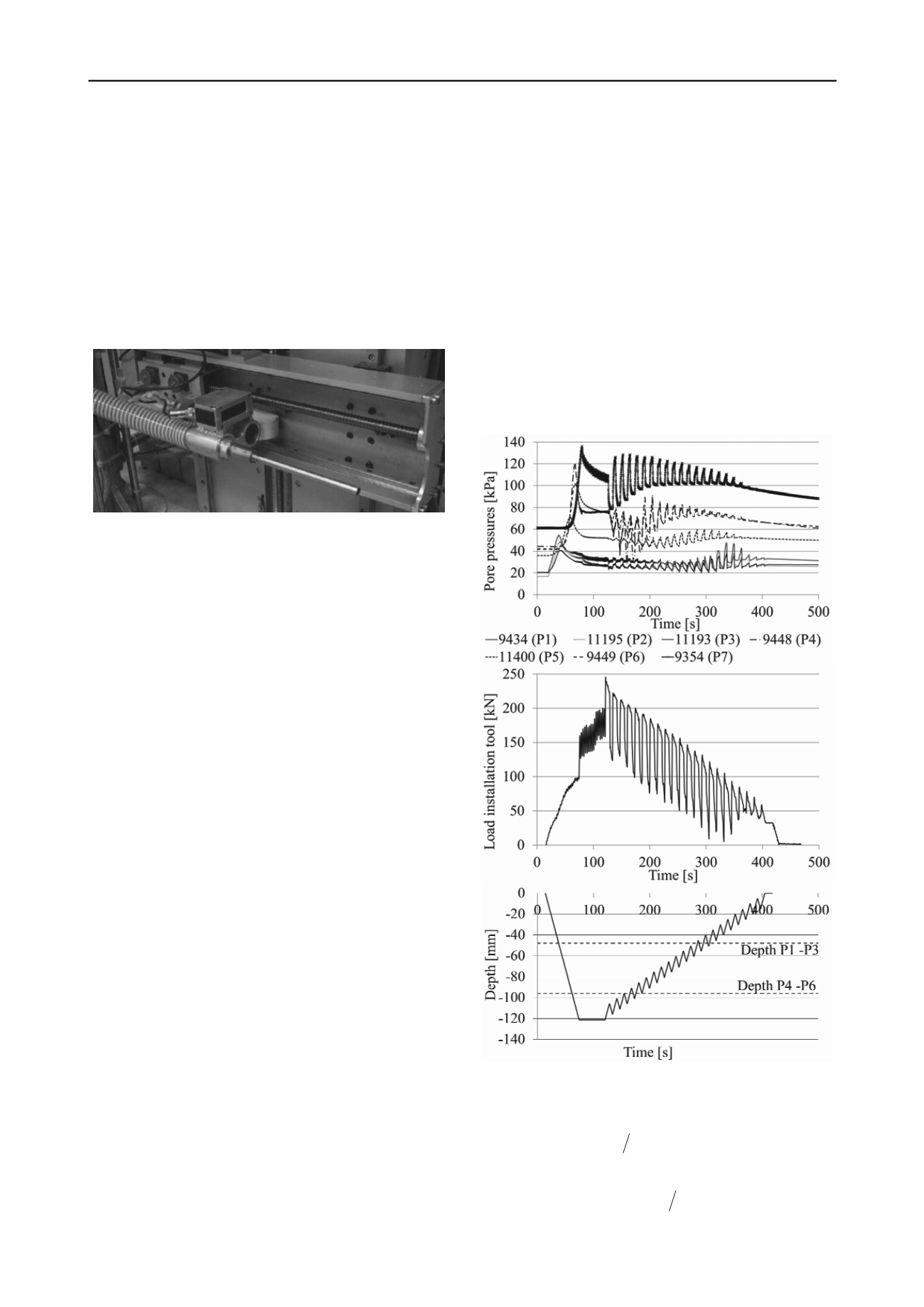

recorded during this phase (Fig. 6). The development of pore

water pressure over time is given in the top part of Fig. 6. The

middle part of Fig. 6 shows the scaled driving force required to

penetrate the installation tool and the bottom part shows the

position of the tip of the installation tool under the surface. It

can be seen that the strongest reaction of the PPTs is observed

when the tip of the column tool reaches the depth of the sensors

(marked by horizontal dashed lines in the Fig. 6c). This is

observed both for the penetration phase and the compaction

phase, respectively.

90% of the excess pore water pressures are dissipated after

about 2300 s, which, when scaled by 50

2

, corresponds to a

prototype time of about 67 days. This is significantly shorter

than the time needed for dissipation of excess pore pressures at

the beginning of the test (see Fig. 4). Indeed, for a drainage path

of 4 m (half of the prototype height of the model) and a one

dimensional stiffness modulus M

E

= 1780 kPa, a coefficient of

consolidation

7 2

2.67 10

/

v

c

m

2

/

589

d c

s

s

is obtained, leading to a

consolidation time at 90% excess pore water pressure

dissipation of

90

90

v

v

t

T

. This reduces the time

by a factor of 8.8, which is consistent with a combined drainage

condition, i.e., vertical plus radially outwards (to the

surrounding Perth sand) and inwards (towards the stone

column) resulting from the insertion of the granular column.

day

6 FOOTING LOADING

As the third step in the test, the newly built stone column

was loaded with a 56 mm-diameter stiff aluminium footing,

after the excess pore water pressures caused by the installation

of the column had dissipated. The loading was displacement-

controlled (v = 0.02 mm/s) and a maximum settlement of

17 mm at model scale was attained before the footing was

removed and the loading-induced excess pore water pressures

were left to dissipate. The first jump in excess pore water

pressures (Fig. 7 top) between 0 and 1000 s is due to a technical

problem, which triggered an unexpected loading of the stone

column. The actual loading can thus be studied after 1000 s.

The sensors P1 (top layer close to the column) and the

sensors P4, P5 and P6 in a depth of 96 mm below ground

surface react in parallel to the loading, albeit with different

magnitudes of pore pressure change, while P2 and P3 exhibit a

less sharp response. This confirms that the column takes a larger

part of the load than the soft clay and the pressure distribution

with depth is not building up as it would in a homogeneous

medium. Secondly, an explanation was sought for the increase

(P1 to P6) or drop (P7) in pore water pressures that can be seen

at about 1500 s, which might have coincided with failure of the

column. A bulge could be identified in the upper third of the

column as the model was being dismantled. The cause might be

attributed to the development of this ‘local compression failure

zone’ in the sand column.

(a)

P7

P4-P6

P5

P1-P2-P3

(b)

(c)

Fig. 6: (a) Pore water pressures, (b) driving force (c) depth of the tip of

the installation tool during the sand column installation.

The total load applied on the footing can be formulated as

(Adam, 2011):

v

sc sc

clay clay

sc

clay

A

A A A

(1)

with the

corresponding load on the stone column as (Adam,

2011):

'

'

1 sin

2

1 sin

sc

sc

clay

clay

sc

c

(2)