1323

Technical Committee 202 /

Comité technique 202

3.3

California bearing ratio (CBR) Tests

The California Bearing Ratio (CBR) test is one of the most

widespread tests to determine strength and bearing capacity of

base, sub- base and subgrades for use in road, railway and

airfields pavements. To demonstrate the influence of lime-

microsilica additive on the bearing ratio of the silty soil, a series

of bearing ratio tests were carried out on stabilized and

unstabilized specimens. The tests were conducted according to

ASTM D 1883 – 99. The soil with different mixtures of lime

and microsilica were compacted in 6" modified proctor mold in

five layers by 56 blows in per layer at the soil optimum

moisture obtained from compaction tests. For curing the

samples, they were placed in constant moisture and temperature

for 28 days. To conduct the tests in soaked condition, they were

immersed in water for 96 hours under the 4.5 Kg (10 pound)

overload according to standard test method. The CBR tests were

carried out after 20 minutes to drain the samples. Meanwhile

swelling potential changes were measured during the soaking

time.

3.4

Wetting - drying tests

After performing the CBR tests, one mixture was chosen as a

desired sample from an economic and resistance viewpoint. To

evaluate the effect of wetting-drying cycles on strength of

selected sample, CBR tests were taken. The desired sample was

rebuilt three more times in the same previous condition on 6-

inch CBR molds. The samples were subjected to wetting-

drying cycles after 28-day curing time and required 96 hours for

soaking. The samples were placed in room to air-dry after

soaking for 24 hours. Then they were again submerged in water

for next 24 hours and thus to expose to one wetting-drying

cycle. This process was repeated 3 and 5 times for samples;

Then CBR tests were carried out on them.

4 RESULTS AND DISCUSSION

4.1

Compaction tests

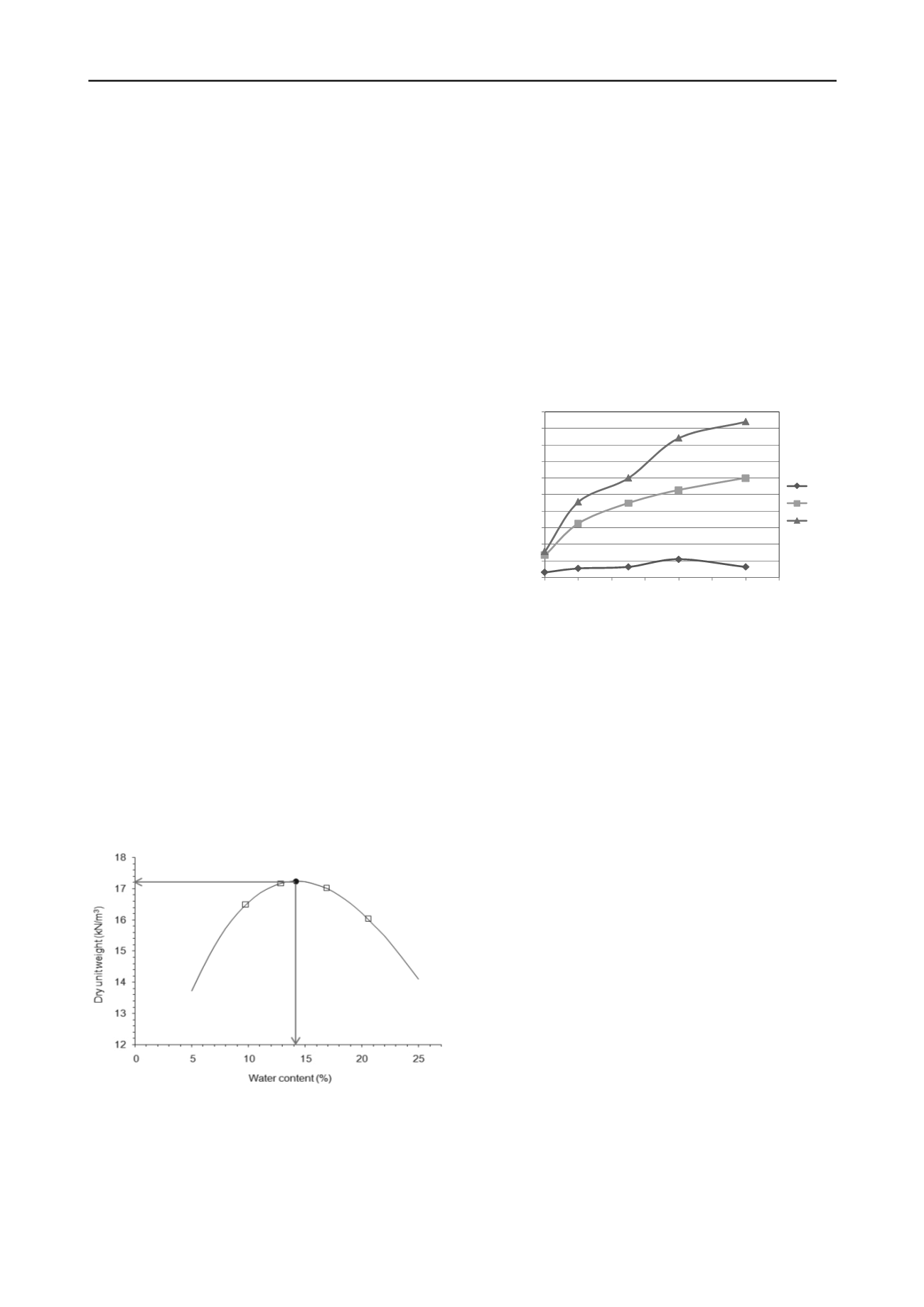

Compaction tests were carried out on the silty soil. The soil

optimum moisture and the soil maximum unit weight were

found to be 14.2% and 17.2 KN/m3 respectively. Compaction

tests results are drawn in Figure 2.

Figure 2. Compaction test curve

4.2

Effect of additives on the CBR

To compare the soil resistant with different amount of additive,

a series of samples were prepared in modified proctor mold.

The CBR tests were conducted in both stabilized and

unstabilized silty soils at the soil optimum moisture with

different amount of lime and microsilica. The CBR value of the

unstabilized soil was 4.8%. The effect of various amount of

additive on CBR values of samples are shown in Figure 3.

From Figure 3, it can be observed that in low amount of lime

(1 percent of dry soil) increase in microsilica amount up to 8%

causes increase in CBR values and then decrease but for 3% and

5% lime increase in microsilica amount causes increase in CBR

values. The maximum CBR value of the samples was occurred

in 5% lime and 12% microsilica. CBR value in this composition

was increased from 4.8% for unstablized soil to 470.8% for the

stabilized soil. So it is seen that up to 466% increase in CBR

value of stabilized soil in compare of unstabilized silty soil.

In addition, it is observed that the dry unit weights were

increased by adding the lime-microsilica additive to samples

and samples moistures were decreased by adding the lime-

microsilica additive to them in overall.

0

50

100

150

200

250

300

350

400

450

500

0

2

4

6

8

10 12 14

1% Lime

3% Lime

5% Lime

Microsilica Content (%)

CBR (%)

Figure 3. The effect of various amount of lime- microsilica additive on

CBR values of stabilized soil

4.3

Effect of additives on samples swelling

The samples swelling were measured during the 96-hour of

CBR samples soaking. There were seen swelling potential rate

were decreased reverse of strength. Unstabilized soil swelling

was 0.55mm and stabilized swelling samples were decreased up

to 0 mm.

4.4

Effect of wetting - drying cycles on samples CBR values

The sample stabilized with 3% lime and 2% microsilica was

chosen as the most desirable sample in terms of economy and

resistance and alternate wetting-drying cycles were conducted

on it. The result of wetting-drying cycles on CBR values of the

sample are given in Figure 4. It is observed that the CBR value

was increased after first wetting- drying cycle. Thereafter the

sample CBR starts to decrease gradually. The reason for

increasing CBR at first is assessed by decreasing in permeation

due to lime- silica fume stabilizer that 96 hours submerging was

not enough for required moisture for the reaction between lime,

silica fume and soil that noticed in introduction section. It is

noteable that the CBR rate after fifth cycle is still more than

initial CBR rate. Therefore wetting- drying cycle not only had

no negative effect on specimen strengths but also help to gain

the soil strength stabilized with lime- silica fume additive.