1322

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

material of industrial applications, it has become the most

valuable by-product among the pozzolanic materials due to its

very active, high pozzolanic property and very fine particles.

These particles are approximately 100 times smaller than the

average cement particle (Karimi et al, 2011).

In previous studies, there have been many researchers

investigating the effects of microsilica on the strength and

swelling characteristics of clayey soils were investigated. It was

seen that microsilica improved the properties of clayey soils

(Kalkan, 2009, Kalkan, 2011, Abd El-Aziz et al, 2004,

McKennon et al, 1994). Likewise, recently, the effects of

microsilica and lime have been investigated on CBR values of

sand (Karimi et al, 2011), (Kalkan, 2009, Yarbasi et al, 2007).

So their effects on cohesionless soils especially silts aren’t

investigated enough yet. Therefore our aim in this study is to

evaluate the feasibility of using stabilized silt with microsilica

and lime for a railway subgrade and then evaluate the effect of

wetting - drying cycles on the soil resistant.

2 MATERIALS

2.1

Soil

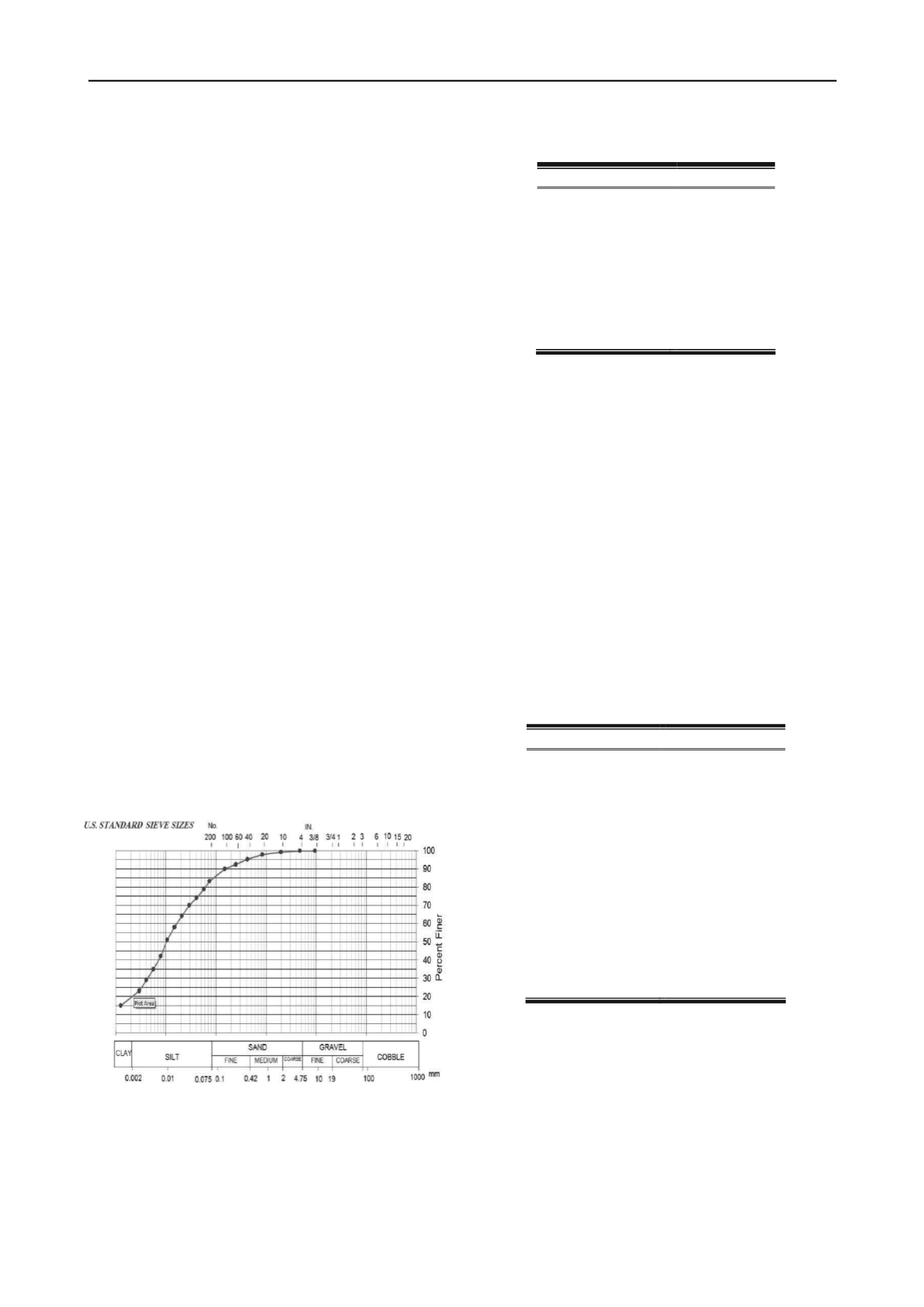

The silt used in this research was obtained from an area in Karaj

railway project in Iran. Atterberg limits tests were carried out

according to ASTM D 4318. The soil Plasticity Index (PI) was

obtained 2. The soil was classified as a low plasticity soil

according to the unified soil classification system ASTM D 422

- 87. The soil name is ML according to USCS (silty soil with

low plasticity). The soil classification is shown in Figure 1.

2.2

Lime

Quick lime which was used in this experiment was obtained

from the industrial group Qom-Iran limestone and its chemical

composition is shown in Table 1.

2.3

Microsilica

Microsilica has been obtained from Ferroalloy Industrial Co

(I.F.I) in Azna. The composition of microsilica mineral is

shown in Table 2.

Figure 1. Grain size distribution curve of the silty soil

able 1. Chemical properties of lime

Chimical names

Percentage

T

K

2

O

SO

3

MgO

4

0.8

2.65

CaO

51.64

Fe

2

O

3

0.13

Al2O

3

0.24

SiO

2

1.36

3 EXPERIMENTAL PROGRAM

3.1

Tests procedure

e- microsilica on CBR values of

Ta 2. Chemical properties of microsilica

Chimical names

Percentage

To evaluate the effects of lim

stabilized silty soils, first the optimum moisture of soil was

calculated from compaction test. Then the soil was mixed with

various contents of lime and microsilica at the soil optimum

moisture. Then the oven- dried soil was sieved from sieve #4

and lime and microsilica were added into them in 1, 3 and 5%

for lime and 2, 5, 8 and 12 percent of dried soil weight for

microsilica. Required amount of water was added to the mixture

to obtain soil optimum moisture, beyond. Time and attention

were paid to provide homogenous soil additive mixture

samples. The CBR tests were carried out on samples which

were cured for 28 days after 96 hours immersing according to

ASTM D 1883 - 99. And at the end, several wetting- drying

cycles were conducted to the optimum mixture of samples

which was economic and had proper CBR values to evaluate the

effect of the cycles on them.

ble

MgO

0.5~2

3

2

O

3

8

re

0.4

CaO

0.5~1.5

Fe

2

O

0.3~1.3

Al

2

O

3

0.6~1.2

SiO

2

90~95

C

0.2~0.4

Na

0.3~0.5

SiO

2

0.04~0.0

MO

0.02~0.07

P

2

O

5

0.04

Moistu

PH

0.01~

6.6~8.8

3.2

Compaction tests

um water content and the soil

To determine the soil optim

maximum dry unit weight, the modified compaction tests were

carried out according to ASTM D 1557 – 91. For this purpose,

the oven- dried soil passing sieve #4 was compacted in five

layers by 56 blows with 4.5 Kg hammer from 45 cm height in

6- inch mold according to procedure C from respective standard

test method.