1083

Technical Committee 106 /

Comité technique 106

- 1

0

1

2

3

4

5

10

12

14

16

Moisture content

(

%

)

Compressive coefficient

change ratio

2684. 9KJ/ m3

2013. 7KJ/ m3

1208. 2KJ/ m3

671. 2KJ/ m3

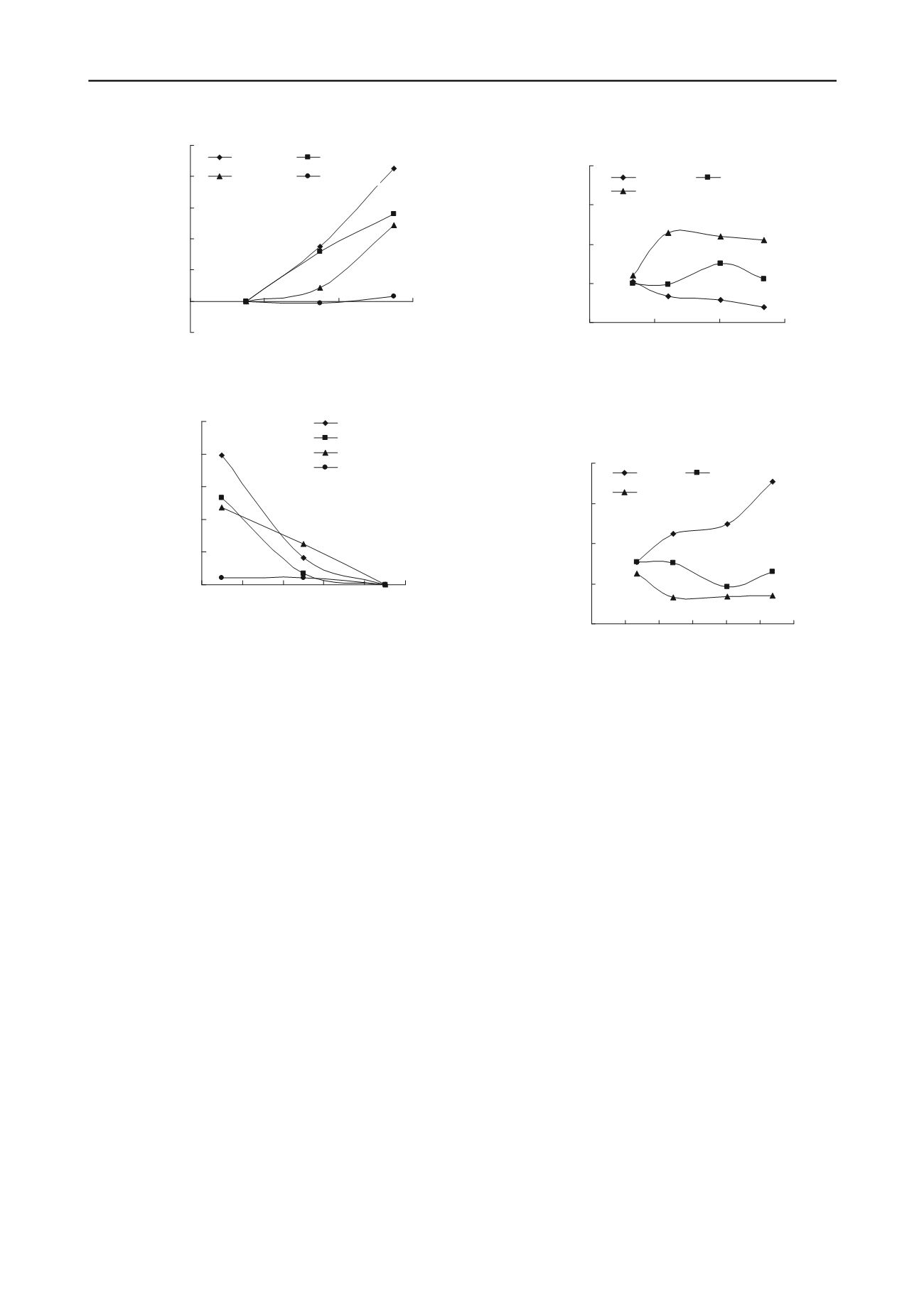

Fig. 4 Change ratio of compressive coefficient vs. initial moisture

content under same compacting energy

0

1

2

3

4

5

11 12 13 14 15 16

Moisture content

(%)

Compressive modulus

change ratio

2684. 9 KJ/ m3

2013. 7 KJ/ m3

1208. 2 KJ/ m3

671. 2 KJ/ m3

Fig. 5 Change ratio of compressive modulus vs. initial moisture

content under same compacting energy

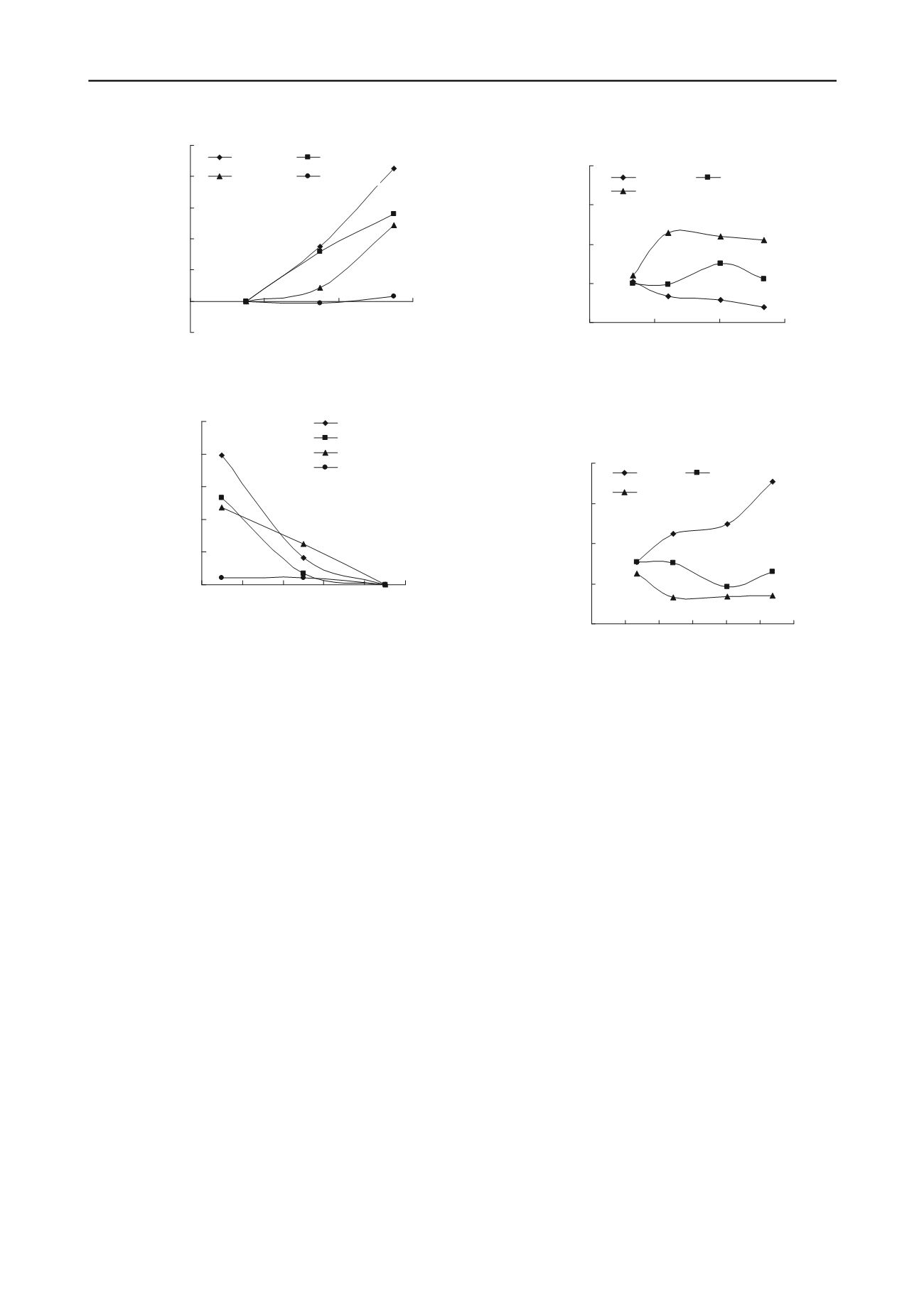

3.3 Compressive property for same compacting energy

At the same initial moisture content, the compressive coefficient

is not monotone decreasing and the compressive modulus is not

monotone increasing with the compacting energy increasing,

seen figs. 6 and 7.

When the initial moisture content equals to 11.5%, the

compressive coefficient is the minimum and the compressive

modulus is the maximum at the compacting energy of 2684.9

kJ/m

3

. When the initial moisture content equals to 15.5%, the

compressive coefficient is the minimum and the compressive

modulus is the maximum at the compacting energy of 671.2

kJ/m

3

. Similarly, when the initial moisture content equals to

13.5%, the compressive coefficient reaches the largest value and

the modulus dose the smallest value at the compacting energy

equal to 1208.2 kJ/m

3

.

Considering the data in table 2, it can be seen that the

maximum compression modulus, meanwhile, the smallest

compressive coefficient is reached when the initial moisture

content is equal or closed to the optimum moisture content

under a particular compaction energy. This emphasises that the

initial moisture content is a very important index for obtaining a

maxmum dry density for given compacting energy. The dry

density represeants the dense condition and degree of

compaction of backfill. Therefore the initial moisture content of

compacted loess like silt is one of the most important control

indexes for the compaction quality control. To get a high quality

of loess like silt backfill, the initial moisture content of the

backfill must be strict controlled when the dry density meets the

design requirement.

0

0.1

0.2

0.3

0.4

0

1000

2000

3000

Compact i ng ener gy( KJ/ m3)

Compressive coefficient

α

1-2

( 1/ MPa)

w=11.5%

w=13.5%

w=15.5%

Fig.7 Curves of compacting energy vs. compressive coefficient at

same initial moiture content

0

10

20

30

40

0 500 1000 1500 2000 2500 3000

Compacting energy (KJ/m3)

Compr

essi

ve modulus

Es

1-2

(MPa)

w=11. 5% w=13. 5%

w=15. 5%

Fig.8 Curves of compacting energy vs. compressive modulus at

same initial moisture content

The initial moisture content of compacted loess like silt is

one of the most important control indexes for the compaction

quality control. To get a high quality of loess like silt backfill,

the initial moisture content of the backfill must be strict

controlled when the dry density meets the design requirement.

4 CONCLUSIONS

In the present study, the following conclusions can be made

about the compressive property of compacted loess like silt.

The maxmum dry density increases and the optimum

moisture content decreases with the increment of compaction

energy.

When the compacting energy is same, the compressive

modulus decreases and compressive coefficient increases with

the increment of initial moisture content.

When the initial moisture content is same, the compressive

iparameters are not monotone changing with the compacting

energy increasing. The maximum compression modulus (or the

minmum compressive coefficient) is reached under a particular

compaction energy when the water content is exactly the

optimum water content corresponding to the compaction energy.

5 ACKNOWLEDGEMENTS

The authors would like to thank the financial supports of

National Natural Sciences Foundation of China (No.51178287)

and Natural Sciences Foundation of Shanxi Province

(No.2010011029).