1079

Technical Committee 106 /

Comité technique 106

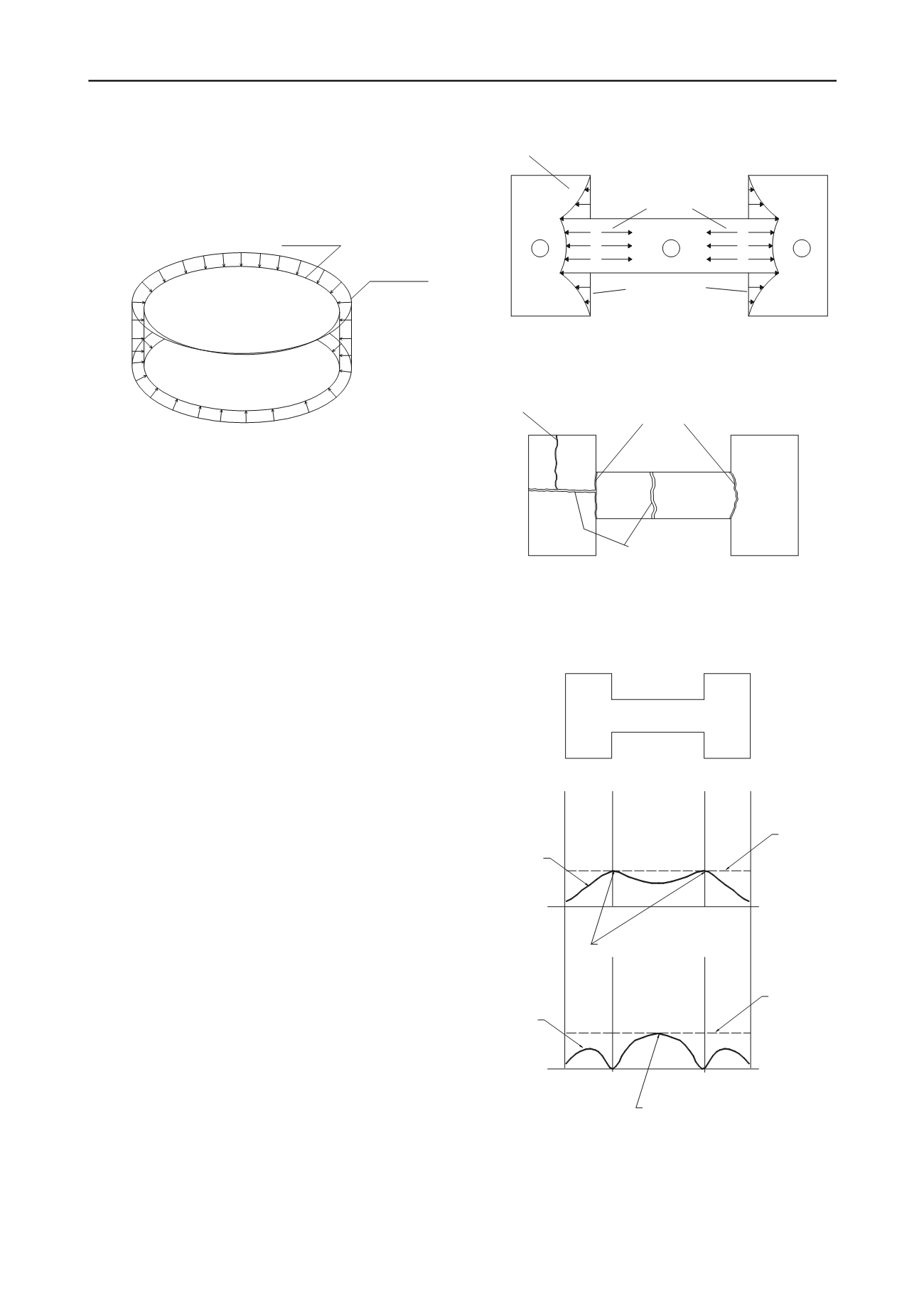

Cylindrical shape is convenient to ensure uniform drying and

homogeneous contractions, however if the base of the mould is

not smooth and friction between the mould and the sample

develops during desiccation, nonhomogeneous tensile forces are

generated producing complex drying patterns.

dry sample

wet sample

Figure 5. Sketch of a uniform and free contraction of a homogeneous

sample subjected to drying. Under these conditions, cracks are not

expected.

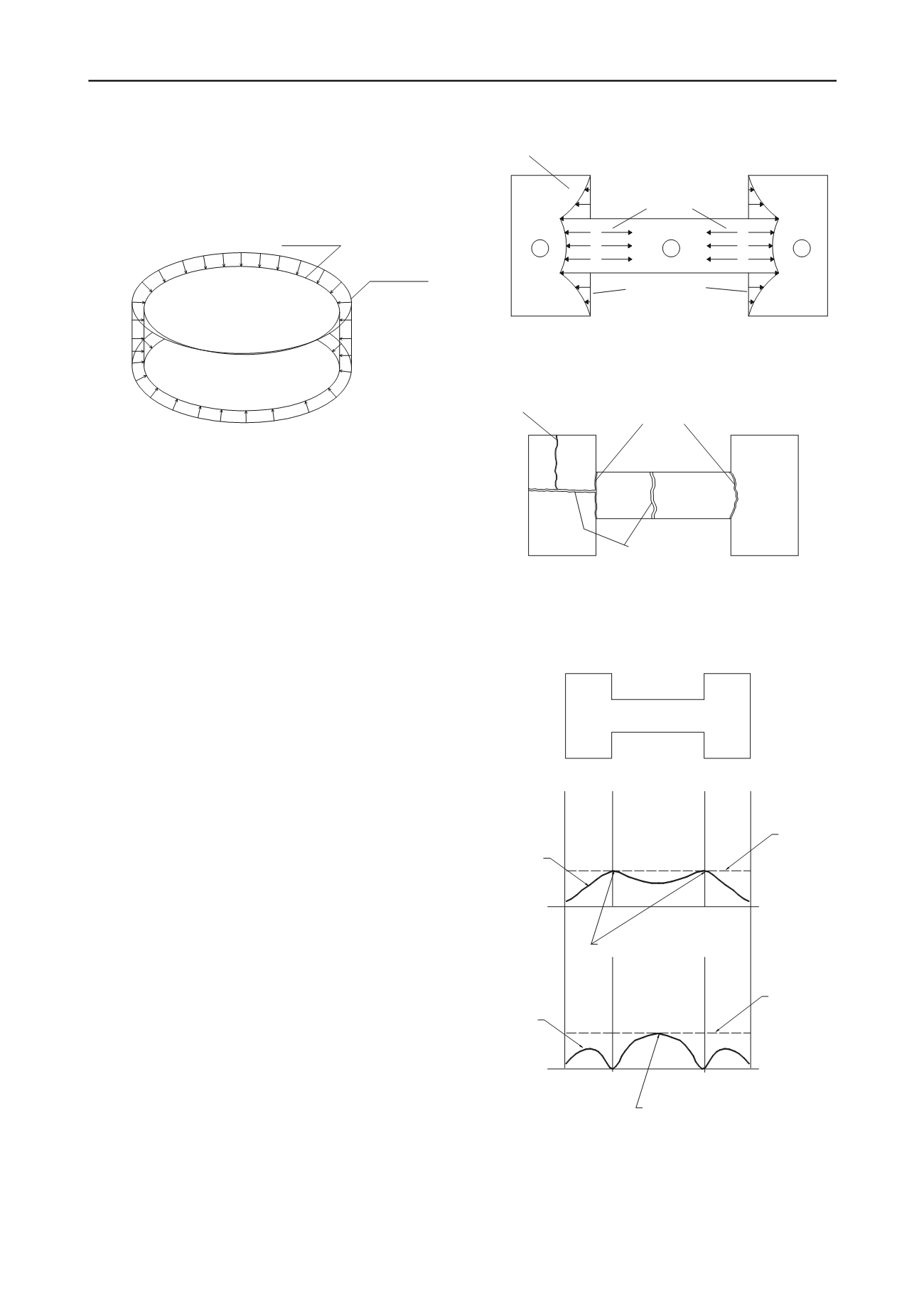

Stress changes are generated as a result of the forces induced

when the soil tends to shrink but the boundary conditions

restrict the free shrinkage. Figure 6 represents a simple picture

of the forces that may progress in the different sectors of the

sample during the desiccation process. Abu-Hejleh and

Znidarcic (1995) and Konrad and Ayad (1997) proposed similar

patterns for desiccation cracks formation in clayed soils

subjected to one-dimensional consolidation and contraction

caused by suction increments. In the central sector (sector 2)

action forces tend to occur due to the contraction of the sample

and these forces are counterbalanced by the reaction forces

generated in the extremes of the sample (sectors 1 and 3) where

the reaction walls play an important role in avoiding the

contraction of the soil. Primary cracks tend to initiate precisely

in the vertices of these reaction walls (points a, f, g or l, in

Figure 6) because it is where an important stress concentration

occurs. Primary cracks progress in a direction perpendicular to

the main action forces, as sketched in Figure 7.

Once the primary cracks have been completely developed,

shrinkage continues and new stress conditions appear in the

different sectors of the sample. In sector 2 (Fig. 6) action forces

are directed to the center of the sample trying to produce

contraction or length reductions whereas reaction forces are

generated by the friction between the soil and the base of the

mould avoiding the sample contraction. As a combination of the

action and reaction forces, non-uniform tensile stresses are

mobilized along the sample. As it is illustrated in Figure 8

primary cracks appear at the points where mobilized tensile

stress equals the tensile strength of the soil (points b and d). In

the points a and e the mobilized tensile stress are low because

restrictions to contraction are not so strong. On point c some

restrictions to shrinkage are produced by the base and sides of

the mould and a tensile stress is mobilized but of lower value

than stress on points b and d. For that reason sample does not

crack at this point.

As soon as primary cracks are completely developed, the

sample stress distribution changes drastically and a sketch of the

possible distribution is depicted in the lower part of Figure 8.

This stress distribution may explain the occurrence of secondary

cracks in the middle of the sample (point c) generated by the

restriction to shrinkage produced mainly by the base of the

mould. In this point mobilized tensile stress equals tensile

strength of the sample.

1

2

3

c

d

e

f

a

b

l

k

j

i

h

g

reaction forces

action forces

reaction walls

Figure 6. Conceptual representation of the forces that may be developed

for producing primary cracking in the sample.

tertiary crack

primary crack

secundary cracks

Figure 7. Position and orientation of primary, secondary and tertiary

cracks in the drying test.

a b

c

d e

Tensile

Strength

Point of initiation of primary cracks

PRIMARY

CRACKING

SECONDARY

CRACKING

Mobilized

tensile

stress

Tensile

Strength

Mobilized

tensile

stress

Point of initiation of secondary cracks

SOIL SAMPLE

Figure 8. Conceptual stress distribution in the sample for producing

primary and secondary cracking.

The tertiary cracks shown in Figure 3 could be generated in a

similar way than the secondary crack. For that reason the cracks