602

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

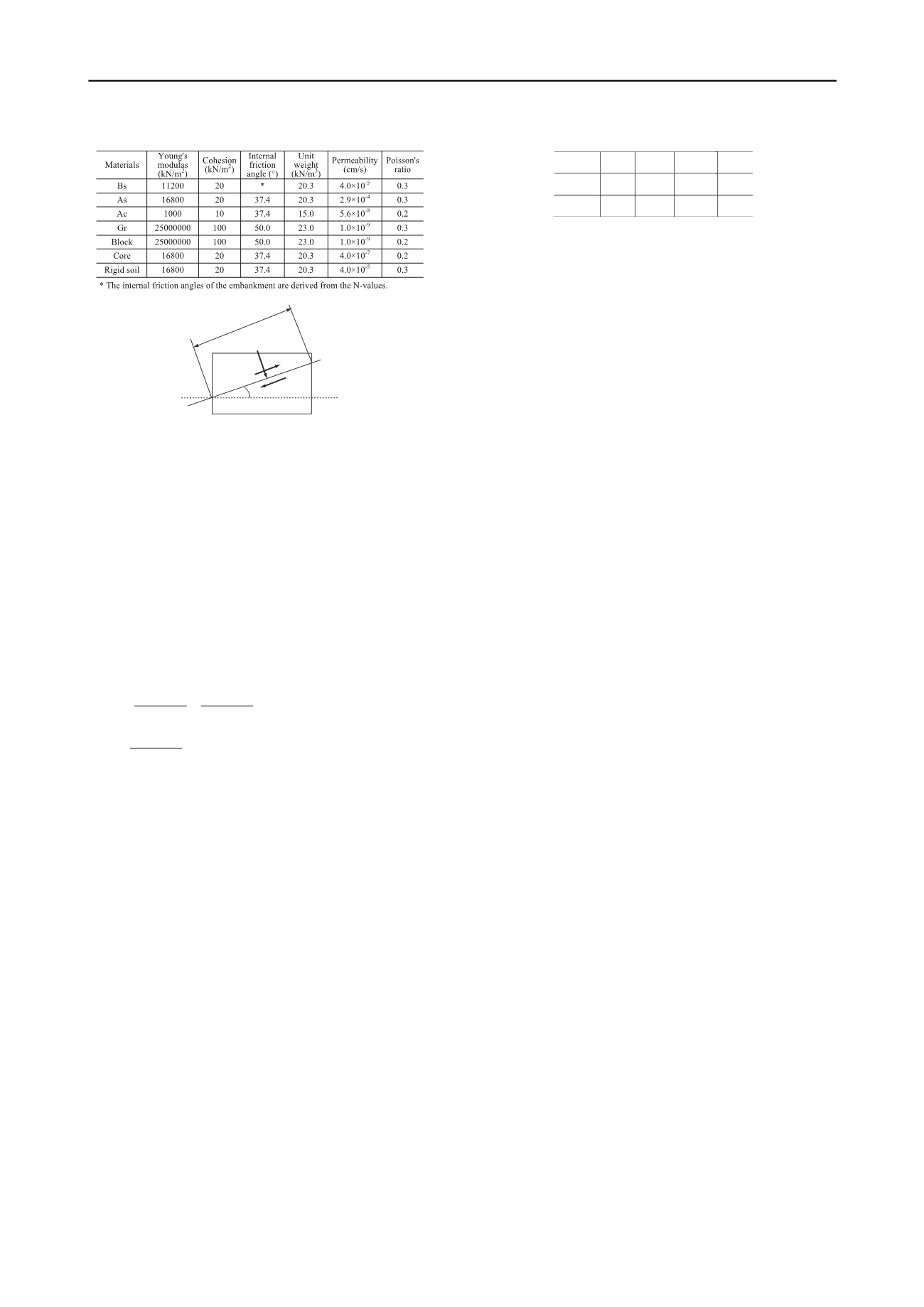

where

f

and

s

are the shear strength and the shear force on the

slip surface exhibited in Figure 6, which shows a slip surface

across a finite element. In the figure,

l

i

is the length of the slip

surface of element

i

, and

n

is the number of elements, which a

slip circle crosses. The strength,

f

is defined by the Mohr-

Coulomb law of Equation (17). Normal stress

n

and shear

force

s

are defined in Figure 6, and calculated with the soil and

water coupling finite element method in this study. In the finite

element analysis, the pore pressure is estimated in the saturated

zone identified with the saturated - unsaturated seepage

analysis, and the negative pore water pressure in the unsaturated

zone is disregarded. This assumption can simplify the analysis

and make an evaluation for the stability that is on the safe side.

f

c

'

n

'tan

'

(17)

n

'

z

'

y

'

2

z

'

y

'

2

cos2

yz

sin2

(18)

s

z

'

y

'

2

sin2

yz

cos2

(19)

in which

c

' is the effective cohesion,

' is the effective internal

friction angle,

z

' and

y

' are the vertical and the horizontal

stresses,

yz

is the shear stress, and

is the angle between a

horizontal plane and a slip surface. The probability failure is

evaluated with Equation (20) through the use of the Monte

Carlo method.

P

f

Pr obability

g

0

(20)

For the internal friction angle

' of the embankment material Bs,

is dealt with as a random variable. Firstly, the random numbers

considering the spatial distribution derived from Equations (12)

and (13) are assigned to the

N

SWS

. Secondly, the random

variable

N

SPT

is evaluated by Equation (2) by considering the

conversion error

r

, and then the

' is obtained with Equation

(14), including the conversion error term 5.3

f

. The Monte

Carlo method is iterated 1000 times.

4.3

Risk evaluation

Two cases of the original embankment and the restored one are

compared, whose cross sections are shown in Figures 5(a) and

(b). In the figures, the representative slip surfaces, which give

the minimum safety factors, are exhibited. In Table 2, the

results of the reliability analysis are shown, in which

F

s

is the

average factor of safety,

P

f

is the probability of failure,

C

f

is the

failure cost, including the damage to houses, agricultural

facilities, and farm lands, and

C

F

is the value of the expected

failure cost. The average factor of safety is almost 1.0 for the

original embankment, and the probability of failure is nearly

20%, which seems very high. For the restored embankment, on

the other hand, the probability of failure is nearly zero and the

evaluated reduction in risk is drastic, at a value of 39,400,000

JPY. The reduction value means the effect of the improvement

work for the embankment.

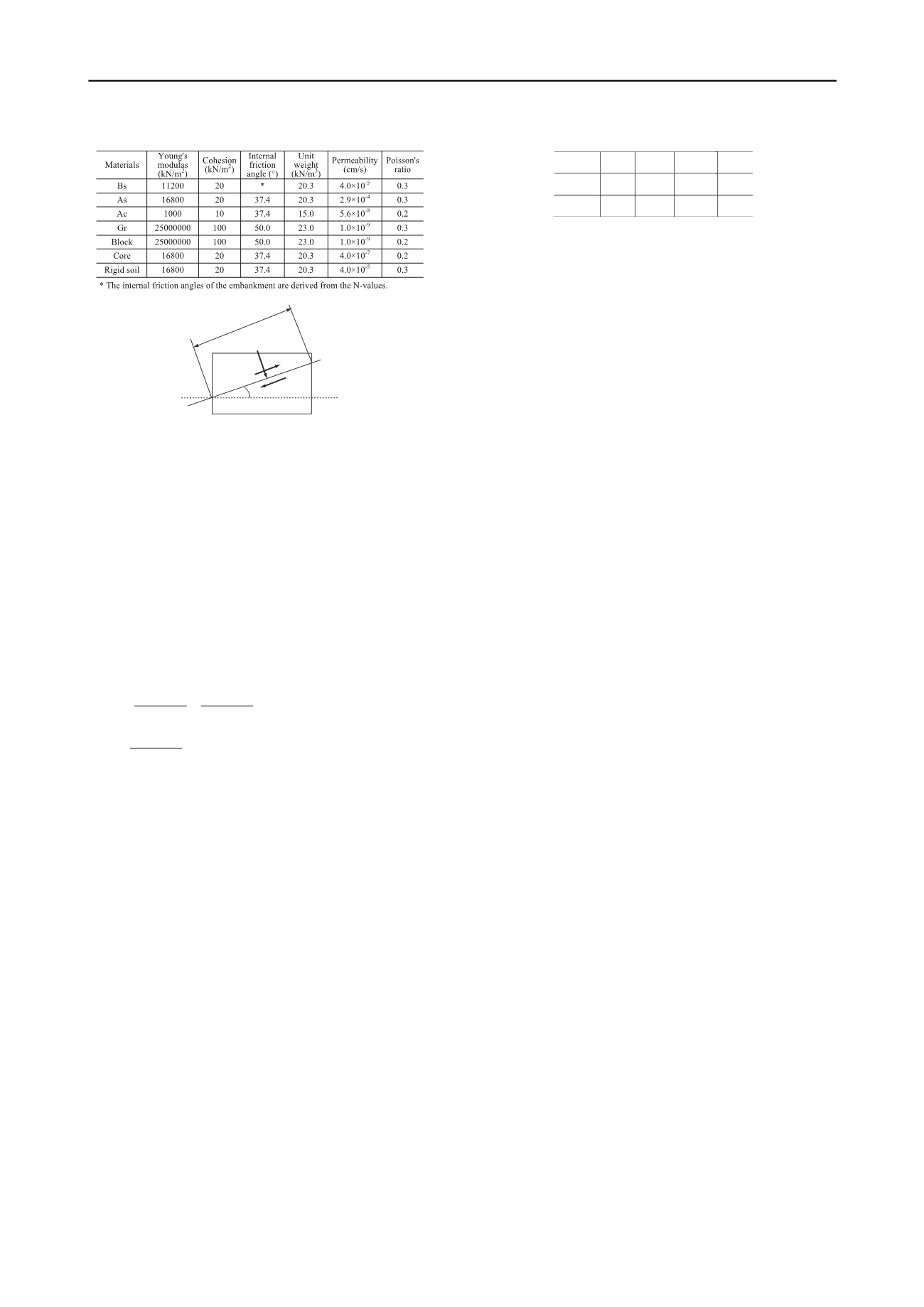

Table 1. Parameters of embankment materials.

θ

l

τ

f

τ

s

σ

n

′

Figure 6. Slip surface across an element

Table 2. Result of reliability analysis.

Fs

P

f

C

f

C

F

Original

1.04 0.197

3,940

Restored

1.62

0

0

Unit (10000 JPY)

2,000

2,000

C

F

=

C

f

⋅

P

f

5 CONCLUSIONS

(1) A method to determine the statistical models of the soil

strength was presented. The indicator simulation, which is one

of the geostatistical methods, was employed. With the proposed

procedure, a detailed spatial distribution of the

N

-values was

exhibited.

(2) Based on the determined statistical model of the internal

friction angle, including the spatial distribution of the

N

-values,

the two conversion errors, from the SWS

N

-value to the SPT

N

-

value, and the SPT

N

-value to the internal friction angle, the

reliability analysis was conducted for an earth-fill embankment,

and the probability of failure was evaluated for the original state

of the embankment and the restored state of the embankment.

By comparing the risks between the original state and the

restored one, the effect of the improvement work of the

embankment was evaluated

6 ACKNOWLEDGEMENTS

This work was partly supported by JSPS KAKENHI

(23248040).

7 REFERENCES

Akaike H. 1974. A new look at the statistical model identification.

IEEE

Trans. on Automatic Control

, AC-19 (6), 716-723.

Cafaro F. and Cherubini C. 2002. Large sample spacing in evaluation of

vertical strength variability of clayey soil.

Journal of Geotechnical

and Geoenvironmental Engineering

128 (7), 558-568.

Deutsch C.V. and Journel A.G. 1992.

Geostatistical Software Library

and User’s Guide

, Oxford University Press.

Inada M. 1960. Usage of Swedish weight sounding results.

Tsuchi-to-

Kiso

, J. of JSSMGE 8 (1), 13-18 (in Japanese).

Journel A.G. and Huijbregts Ch.J. 1978.

Mining geostatistics

, Academic

Press.

Hatanaka M. and Uchida A. 1996. Empirical correlation between

penetration resistance and internal friction angle of sandy soils.

Soils and Foundations

36(4), 1-9.

Nishigaki M. 2001.

AC-UNSAF3D User's Manual

. (in Japanese).

Shinoda M., Horii K., Yonezawa T., Tateyama M. and Koseki J. 2006.

Reliability-based seismic deformation analysis of reinforced soil

slopes.

Soils and Foundations

46 (4), 477-490.

Soulie P., Montes P. and Silvestri V. 1990. Modelling spatial variability

of soil parameters.

Canadian Geotechnical Journal

27. 617-630.

Tang W.H. 1979. Probabilistic evaluation penetration resistances.

Journal of the geotechnical engineering

, ASCE, 105(GT10). 1173-

1191.

Uzielli M., Vannucchi and Phoon, K. K. 2005. Random field

characterization of stress-normalized cone penetration testing

parameters.

Geotechnique

55(1), 3-20.

Yoshida, I., Arakawa, T., Kitazume, T. and OOtsu H. 2005. Study on

seismic probabilistic safety assessment of a slope,

Journal of

geotechnical engineering

, JSCE, No.785, 27-37.