Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013, volume 6, 2016

6.3

Publications

2006 Technical Guide:

Vibratory pile driving

- Vibratory

pile driving,

Presses des Ponts et Chaussées

, ISBN 2-85978-

423-3, 282 pages. This technical guide, released in 2006,

provides answers, in light of current knowledge and extensive

experimental results, to questions raised by users of the vibratory

pile driving technique, including:

- choosing the appropriate technique and equipment;

- planning pile inserts and efficiency (BRAXUUS software);

- determining possible nuisances during pile-driving works;

- estimating the load-bearing capacity of piles once installed.

This guide includes: a text in both French and English

describing the instruments, their associated options, the existing

computation software, an analysis of pile-driving and load-

bearing capacity test results, a bibliography, a list of standards

and recommendations, and lastly internal NP reports.

Appendix A compiles a set of theoretical contributions, while

Appendix B provides a summary of the experiments, both full-

scale and in the laboratory. Appendix C presents the vibratory

pile-driving prediction software, in particular the BRAXUUS

application for the National Project (downloaded on a CD-ROM

to accompany the guide). Appendix D contains the pertinent

documentation of contractors partnering in the project.

Holeyman A., Vanden Berghe J.-F., Charue N. (2002)

TRANSVIB 2002:

Vibratory pile driving and deep soil

compaction, Balkema, ISBN 90-5809-521-5, 233 pages.

Gonin H., Holeyman A., Rocher-Lacoste F. (2006)

TRANSVIB 2006:

Proceedings of the International Symposium

on Vibratory pile driving and vibratory compaction, published

by LCPC, ISBN 2-7208-2466-6, 400 pages.

TRANSVIB is an international symposium held periodically

to convene individuals and organizations interested in vibratory

pile driving, sheet-pile driving and deep pile compaction; these

gatherings have given rise to published proceedings. The first

symposium took place in 2002 in Louvain-la-Neuve, Belgium,

and the second four years later in Paris to showcase and extend

this NP on vibratory pile driving. It would be highly beneficial to

organize a third session in the near future.

6.4

Remarkable results

6.4.1

Penetration into the soil

This discussion will merely highlight, from among the extensive

body of experimental data and their associated interpretations,

what has struck us to be especially innovative and capable of

advancing the state of knowledge and understanding of the

phenomena under observation.

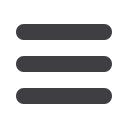

For starters, all measurements of time-dependent variables

have proven to be periodic and, as such, may be broken down

into a constant value over the considered period (i.e. an average

value) and a time function whose average single-period value

equals zero. The penetration speed may be assumed constant

over a single period, with a zero average acceleration.

Yet these measurements have demonstrated that the effect of

vibrations cannot be summarized as a decrease in friction along

the pile shaft: penetration is not solely due to the weight of the

pile + vibrodriver + clamps assembly. Periodic variations and

alternating pile particle velocities also serve to mobilize friction

forces in order to help overcome soil resistance at the pile tip, as

observed on graphs depicting the average values of friction

forces and pile cap strength for the Merville site tests (pile-tube

and sheet pile) (Fig. 11).

Fig. 11: Pile tip force and lateral friction - Average values

Interpretation of these measurements has actually enabled

separating the force exerted by the soil under the pile tip from

the lateral effects on the pile shaft. Two distinct methods were

employed for this purpose during the NP. Attention should be

drawn to the analysis presented by Dominique Vie in the 2006

Transvib Symposium proceedings (LCPC, ISBN 2-7208-2466-6,

pp. 195-208). The method applied, based on a rigorous analysis

of vibration measurement recordings, should in our opinion

dictate measurement interpretations conducted on jobsites

whenever recordings at the pile top and tip or at several levels

(including one above ground) are available.

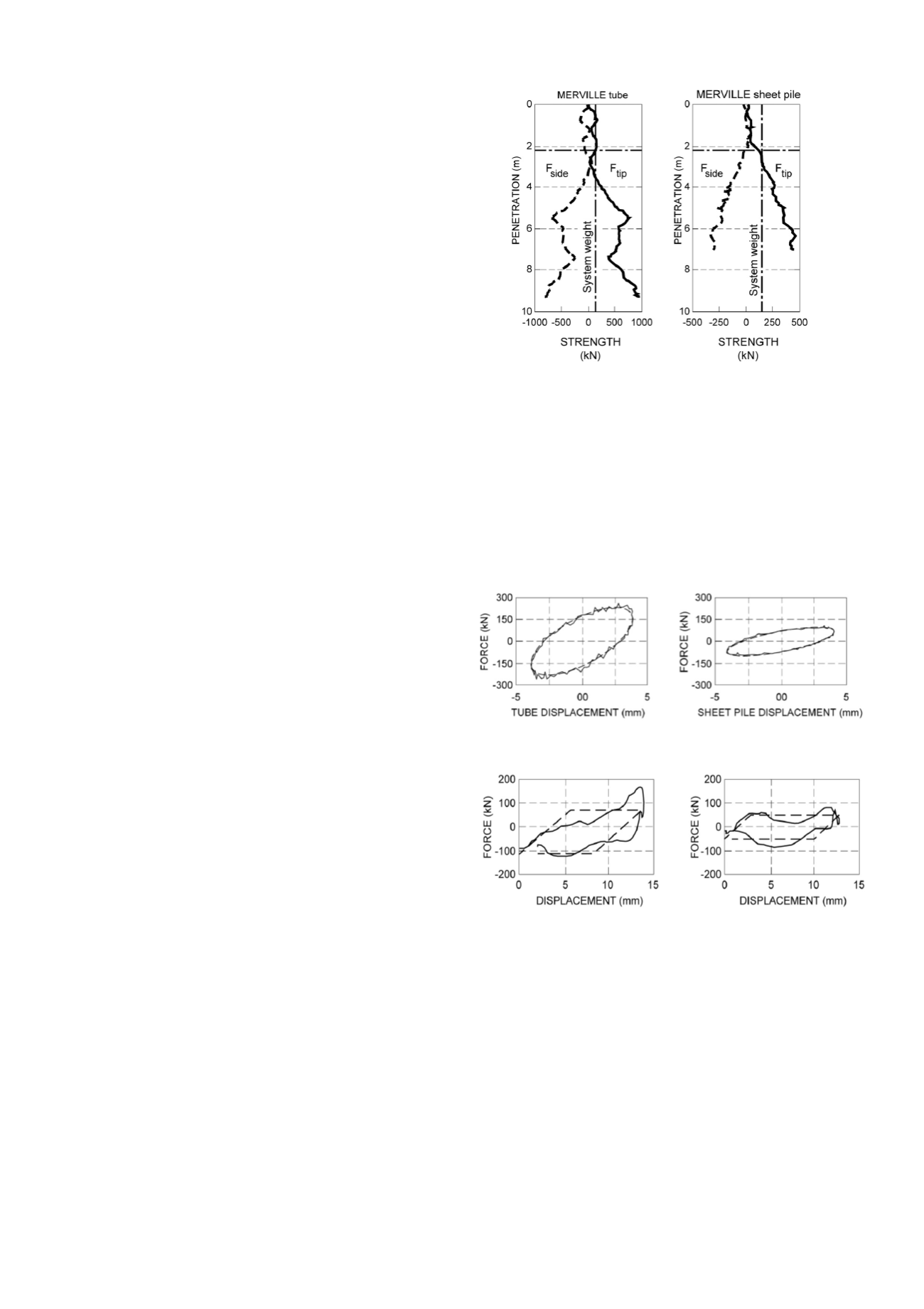

Fig. 12: Modeled behavior measurements and laws - Merville site

Fig. 13: Modeled behavior measurements and laws - Montoir site

For purposes of illustration, the above figures present the

force-displacement graphs (of just the periodic components)

obtained at Merville (Fig. 12), for the tube and a sheet pile, and

for the tubes at Montoir (Fig. 13), showing both the tip and the

resultant of lateral friction. Let's recall the nearly perfect

elliptical shapes derived at Merville (Fig. 3), which could be

accurately modeled by a linear viscoelastic law, whereas an

elastoplastic modeling law is less apparent for the Montoir tests.

6.4.2

Load-bearing force of the vibratory-driven piles

Subsequent to the bibliographical research and experimental data

collected through instrumented tests with a full-scale strain

gauge chain (Fig. 14), recommendations were devised to design

the piles set into place by means of vibration. Compared to

openly hammered tubes, hammered H-piles and hammered sheet

Volume 6 - Page 85