Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013, volume 6, 2016

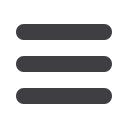

Fig. 10: Vibratory pile driving: Schematic diagram (Holeyman, 2002)

This work was wrapped up in 2006 by the publication of a

Vibratory Pile Driving Technical Guide, simultaneously in

French and English, distributed to attendees of the "

2006

Transvib

" International Symposium, held in September 2006 in

Paris, and widely disseminated since then.

6.2

Program framework

The studies and research conducted during this

Vibrofonçage

NP

contained three segments, each one composed of several phases:

-

Segment 1:

survey of practices, summary of previous

research projects, and preparation of Segment 2 (including

in

situ

testing and experiments);

-

Segment 2:

Execution of instrumented

in situ

vibratory pile

driving and pile loading tests, plus calibration chamber tests in

the laboratory;

-

Segment 3:

Analysis and interpretation of experimental

results, development of a computation code for vibratory pile

driving predictions (BRAXUUS software), issuance of a

technical guide, results presentation (organization of the 2006

Transvib Symposium).

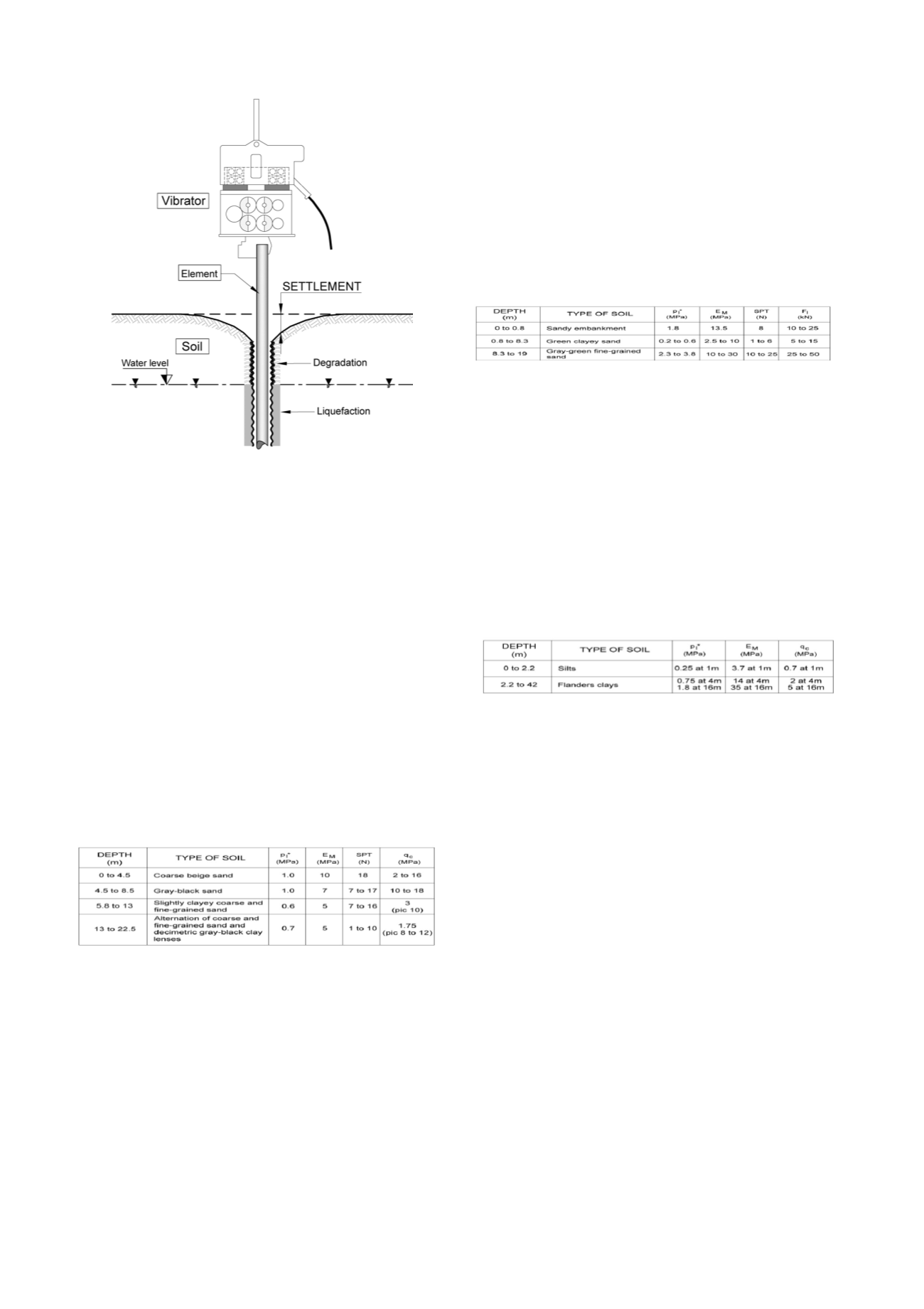

Table 3: Geotechnical characteristics - Montoir site

Segment 2 experiments were held across four sites:

The Montoir tests were conducted in August 2001. A series

of full-scale tests took place at the time of expanding the freight

and container terminal at the Montoir Port (Nantes-Saint Nazaire

Port Authority).

The ground cross-sections and their geotechnical

characteristics are summarized in Table 3 above.

Two metal tubes closed at the 339-mm diameter, 14-mm

thick (length: 32 m) and instrumented at several levels (stress

gauges, accelerometers) were driven by vibration. One pile was

over-driven in order to evaluate its load-bearing capacity by a

dynamic test. A static loading test was then performed on the

other pile, for comparison with the results of a static loading test

on a driven pile of the same type at the same site in 1999.

The

Dunkirk

tests conducted in January 2002 involved three

tubes open at the base of a structure under construction and

driven by vibration; these tubes were fitted at the top with strain

gauges and accelerometers (a pile-driving control device

developed by TNO). Measurements recorded just at the top did

not give rise to any detailed interpretation.

The

Le Havre

tests were carried out in December 2002 at a

site made available by the Le Havre Port Authority in the zone

around the petrochemical facility adjacent to the Normandy

Bridge.

The ground cross-sections and geotechnical characteristics

are summarized in Table 4 below:

Table 4: Geotechnical characteristics - Le Havre site

A PU16 sheet pile (length: 14 m) and a probe (length: 14.5

m) used during a pervious experiment (i.e. a SIPDIS probe) were

installed. The probe had been instrumented on three levels, while

the sheet pile was fitted at both the top and tip, with one tube at

the top and tip and the other only at the top. Particle velocity

measurements at the soil surface were recorded during

installation of the two tubes and probe.

The

Merville

tests were undertaken from March to June 2003

at the Merville Airfield experimental site, under the supervision

of the LCPC. They were intended to measure, for comparative

purposes, the behavior of hammered and driven piles by means

of vibration into Flanders clay soils.

Their ground cross-sections and geotechnical characteristics

are summarized in Table 5 below:

Table 5: Geotechnical characteristics - Merville site

Two open tubes (length: 12.3 m) 508 mm in diameter, plus

two pairs of AU16 sheet piles (length: 13 m), were installed

under experimental site conditions. For each type of element,

one was driven by vibration using an ICE 815 vibrodriver while

the other was hammered to the same depth with an IHC S70

hammer. The elements were instrumented at both the top and tip.

The hold-down force, penetrating pile length, pressure and flow

rate of the hydraulic unit for this vibratory pile-driving test, the

hammer energy for hammering, and particle velocities at the soil

surface for distances of 5, 10 and 15 meters from the element

were all measured continuously during the pile penetration. Each

element was then subjected to an instrumented static loading test

in order to compare the load-bearing capacities obtained for each

of the two installation modes.

As a complement, physical modeling tests of the pile-driving

process by means of vibration were conducted inside the

CERMES calibration chamber at the ENPC Laboratory in

Marne-la-Vallée. A prototype vibratory pile-driving probe was

developed for penetration into a sand block reconstituted in the

chamber thanks to a hydraulic servo-cylinder. The probe, with a

10-cm

2

cross-section (i.e. the penetrometer standard), had been

instrumented to measure the pile cap strength as well as local

friction on a special sleeve. Moreover, the probe was fitted with

a tapered accelerometer. The parametric study completed by

relying on controlled force and controlled displacement tests

clearly exposed the influence of basic parameters (average static

force, amplitude and frequency of the cyclic force) on process

performance. These tests have given rise to a physical model that

may be simulated by running certain software, in particular the

BRAXUUS application developed during this NP.

Volume 6 - Page 84