Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013, volume 6, 2016

curves (as well as the

q-z

p

pile tip strength curve). The GOUPEG

Program was validated by comparing the interaction coefficients

F

obtained with well-known solutions within the elastic

continuum of Poulos and Davis (1990).

5.3.2 Interpretation of the Rueil-Malmaison tests

These tests were conducted on 4 vertical micropiles: 1 isolated

micropile, and a group of 3 micropiles spaced 1 m apart and

pulled in tension. These micropiles were composed of steel tubes

with: diameter B = 89 mm, a free length of 14 m in the alluvia,

and a sealed length of 5 m in the underlying chalk (B = 125

mm). They were instrumented in 8 sections with the LCPC

removable extensometer in order to determine friction along the

shaft. Several tensile loading calculations were performed with

GOUPEG; each time the skin friction mobilization laws applied

were those of Frank and Zhao. For the interaction between

micropiles and use of Mindlin solutions, a Young's modulus of

E=10 E

M

(E

M

: pressuremeter modulus) was adopted.

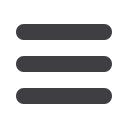

Fig. 7: Comparisons between measured and calculated tensile loading

curves of grouped micropiles (Rueil-Malmaison tests)

Figure 7 provides comparisons between the loading curves

measured at the top of each micropile in the group and the

curves calculated with GOUPEG, according to 2 hypotheses for

the limit skin friction (I: average value measured on the isolated

micropile; and II: average value measured for the group as a

whole). These results are satisfactory, in recognizing that the free

length of the isolated micropile is less than 14 m due to a rise in

the level of grout.

5.3.3 Analysis of the St Rémy transverse loading test

The GOUPEG Program was then extended to include an analysis

of micropile groups subjected to transverse loading, once again

in relying on Mindlin's equations. This analysis led to examining

both the vertical and horizontal loadings of full-scale tests

conducted in the sand at the CEBTP's St Rémy experimental

site, which included both isolated micropiles and two groups of

4 micropiles with the following parameters: S/B = 2; D = 5 m; B

= 10 cm; and I

D

= 0.57. The data required for this analysis were

the "

t-z

" curve of skin friction, the "

q-z

" curve of pile tip strength

and the "

p-y

" curve of transverse strength, with all these curves

being exclusively derived from on-site pressuremeter tests. To

calculate the group effect (i.e. the pile-soil-pile interaction), the

soil shear modulus G (input into Mindlin's equations) needed to

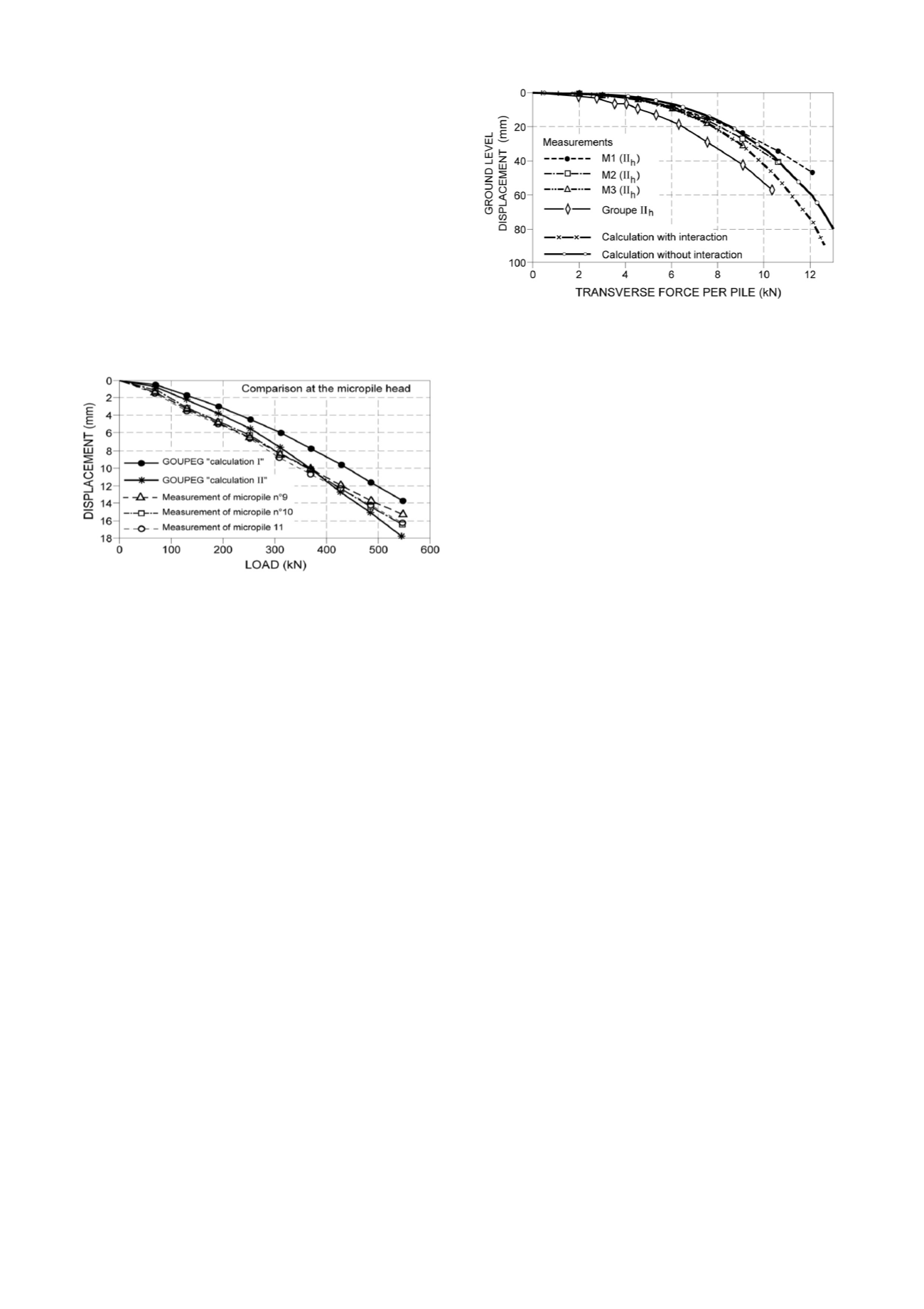

be evaluated. Figure 8 shows the comparison of experimental

results with GOUPEG calculations for the type II micropile

group (with gravity grouting). It can be observed that the

pressuremeter method developed for piles is also valid for

micropiles and moreover that for a given micropile group, the

trend yielded by GOUPEG represents reality quite well.

Fig. 8: Comparison of the force-displacement curves both measured and

calculated by GOUPEG, in the horizontal loading of

a type II micropile group (St Rémy test)

5.4

Networks of vertically-loaded micropiles

Experimental research on micropile networks, in which all

micropiles are inclined and vertical loadings have been

introduced, is uncommon. The large number of tests conducted

during

FOREVER

on vertically-loaded networks in sand have

made it possible to analyze the influence of the following

parameters: micropile spacing, sand density, and micropile

density and interlocking.

Within a network, micropile orientation is characterized by

two angles: angle

of micropile inclination with respect to the

vertical, and angle

, the so-called interlocking angle, between

the vertical plane containing the micropile and the vertical plane

tangent to a horizontal circle centered at the middle of the

foundation and passing by the micropile top. An interlocking

network is characterized by negative

values (

< 0° or > 180°),

which enables the micropiles to be spaced at smaller distances

than at the top, thus leading to greater soil confinement between

micropiles.

The initial experimental results were obtained by Lizzi

(1978), who used a 1/10 reduced-scale model to compare the

behavior of a group to that of a network, with each containing 18

micropiles. The improvement offered could be quantified either

by the coefficient of efficiency C

e

= 1.68, which indicates the

ratio of the load-bearing capacity of the group to that of all

isolated micropiles, or else by Ce = 2.22, i.e. the ratio of the

load-bearing capacity of the network to the sum of the load-

bearing capacities of all isolated vertical micropiles.

The

FOREVER

NP performed a series of 20 tests on

micropile networks in sand (full-scale, centrifuge, tank,

calibration chamber) by means of varying the parameter values.

The initial result was a wide dispersion in values of the Ce

coefficient (from 0.51 to 2.93), which can be explained in part

by the micropile installation mode: driving, boring, cast-in-place.

The relative S/B spacing does not appear to be a main parameter.

Sand density could hardly be studied since for all tests, the

density index I

D

of the sand was in the vicinity of 0.5, which

corresponds to a relatively loose sand. Regarding micropile

density or number N, it would appear that a minimum number of

micropiles per unit volume is required to generate a positive

group effect. As for micropile orientation and the values of

angles

and

, it also remained impossible to determine a

precise effect since too few tests actually allowed varying one of

these two parameters while keeping all other parameters

constant. It could nonetheless be confirmed that inclining an

isolated micropile hinders its vertical load-bearing capacity,

when compared to the load-bearing capacity of the same

micropile placed in a vertical position. On simple networks

composed of easels (A-shaped) however, results showed that a

mechanism specific to inclined micropiles developed during

vertical loading, involving the gradual mobilization of a passive

pressure with bending on the micropiles. This phenomenon,

Volume 6 - Page 81