Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013, volume 6, 2016

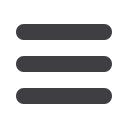

4.2.1 Wall No. 1 in a nailed soil stressed until failure

This 7-m high wall installed in sand was built by completing a 1-

m high excavation phase with sealed nails 6-8 m long, in

offering some bending strength due to its tubular composition.

The structure had been calculated using a sufficiently small

overall safety coefficient (F=1.1), capable of easily causing

breaking as the soil gradually saturated from the top of the wall,

thus reducing the sand's apparent cohesion while increasing its

total specific gravity. Thanks to the extensive instrumentation

installed, it was possible to perform a large number of

measurements (tension in the nails, facing displacement, strain in

the nailed soil mass, etc.). Moreover, since the failure was not

complete, given that the facing had penetrated and become

blocked in the foundation soil, excavating the wall allowed for a

comprehensive investigation of the failed wall (Fig. 3).

Fig. 3: Observations recorded during excavation of the nailed soil wall

after failure (1

st

full-scale experiment held at the CEBTP site)

More specifically, nail bending in the vicinity of failure

creates a shear zone in the soil around the line of maximum

tension points in the nails; as a general rule, it also yields a non-

abrupt, and rather ductile, wall failure appearance.

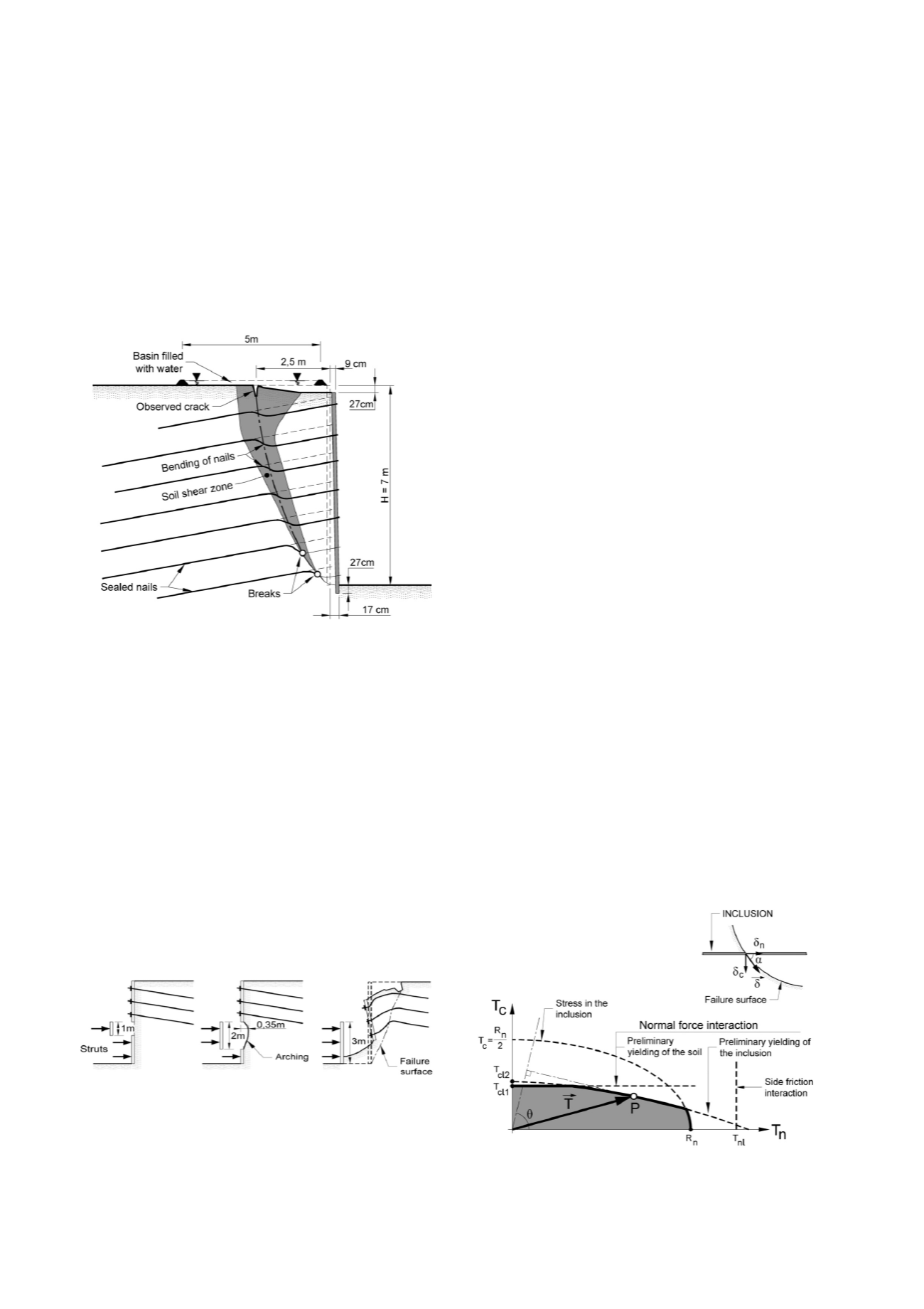

4.2.2 Nailed soil wall N°2 under study during the excavation

phase

The objective of this experimental wall No. 2 tested at CEBTP

was to study the stability, both local and global, of a nailed soil

mass during an excavation phase. For this purpose, a nailed soil

wall 3 m high was first built and then stressed until failure by

increasing the excavation height from 1 to 3 m at the wall base.

During the first stage (i.e. 1-m excavation height), both the

excavation and wall were stable. For the second stage (2-m

excavation height), a localized failure ensued followed by

stabilization through the formation of an arch, yet overall the

wall remained stable. Lastly, for the third stage (3-m height), the

arching collapsed and local failure propagated all the way to the

surface, resulting in a global and internal wall failure.

Fig. 4: Stability and failure during the excavation phase of

the CEBTP's nailed soil Wall No. 2

4.2.3 Wall No. 3 in nailed soil - failure caused by insufficient

nail length

The third experiment at the CEBTP site on a nailed soil wall,

this one 6 m high, served to examine the failure mode due to

insufficient reinforcement length. This wall was equipped with

adjustable length telescopic nails. Failure occurred once a

distribution of very short nails had been reached along the base

of the wall with gradually increasing nail length towards the

upper part of the wall. This configuration dictated the shape of

the sliding surface, which corresponded to an intermediate

failure somewhere between an adherence deficiency mode and

an external failure mode.

4.3

Primary results from Clouterre I

Wall No. 1 revealed the shape of the maximum tension line in

the nails, i.e. remaining constant until the initiation of failure,

which is gradual, along with a certain trend towards nail bending

in the vicinity of failure.

Wall No. 2 indicated that wall stability during its construction

had been correlated with the development of an arching effect

over the course of excavation phases, which provided

information on process limitations among other things.

Soil/nail friction has been the topic of in-depth studies

involving both experimental and theoretical findings, with, like

in the Reinforced Earth technique, the notion of an apparent

friction coefficient

* correlated with a partially impeded

dilatancy of the granular part of the soil skeleton.

A major portion of the research was devoted to developing an

ultimate limit state (ULS) design method. The preference was

assigned to a failure method that makes use of circular failure

surfaces, calibrated with the full-scale wall No. 1. More

specifically, a so-called multicriteria method was developed

(Schlosser, 1982) to enable determining the torsor (T

n

, T

c

, M) of

forces at the point of maximum tension in a nail. This method

relies on a set of failure criteria focusing on components and the

interactions between components, namely:

- soil/nail skin friction interaction:

q

s

- soil/nail transverse pressure interaction: p

p

max

- nail constituent material:

k (max shear)

This work has led to identifying 4 criteria, in acknowledging

the assimilation of nails to beams, thus giving rise in the (Tn, Tc)

plane of tensile and shear forces to a domain of stability that

helps determine the maximum resultant force (Fig. 5).

These multiple criteria allow for a shear force in the nails that

often gets neglected when designing nailed soil walls, yet that

becomes a predominant concern when vertical nailing is used to

stabilize slopes. This design method was the first in the field of

soil mechanics to use a semi-probabilistic calculation with

partial safety coefficients and weighting coefficients on actions.

It has now become the rule in the Eurocodes.

Fig. 5: Domain of stability in the (T

n

, T

c

) plane,

and determination of maximum force T

Volume 6 - Page 78