Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013, volume 6, 2016

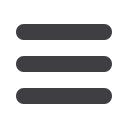

Fig. 18: Force-displacement relations at the pile head during repeated

compression tests on the bored F5 pile at Merville (according to Benzaria

et al.

, 2013b) - Comparison with the standard static test on pile F4

8.2.4

Cyclic stability diagrams

The result of a cyclic pile test may be more effectively

summarized using a cyclic interaction diagram. Each test is

depicted on a Q

cy/

Q

us

diagram by a point relative to Q

a

/Q

us

, with:

Q

cy

= half of cyclic amplitude; Q

a

(= Q

m

) = average load; and

Q

us

= ultimate reference static load. Q

us

is determined based on a

standard static test conducted in either compression (Q

uc

) or

tension (Q

ut

) depending on the tested loading mode. Each point

is assigned the number of cycles (N

f

) required for the pile to fail

according to a given criterion or else the total number of cycles

applied to the pile. Once a sufficient number of tests have been

completed (on the order of 10 or 20), it is possible to delimit

those zones where pile stability is guaranteed for a certain

number of cycles and other zones where cyclic failure is

obtained after a smaller number of cycles. An appropriate term

to employ would thus be "cyclic stability diagram".

One fundamental contribution of the SOLCYP project is to

have generated cyclic stability diagrams for various types of

piles: driven, bored CFA, and screwed; driven into

overconsolidated clays and dense sands; with one-way loadings

(in both compression and tension) and two-way loadings; and by

applying high numbers of cycles (up to 10,000 per series). These

diagrams were derived not only from

in situ

tests on

experimental piles, but also from tests on model piles.

For purposes of illustration, let's provide two diagrams, one

obtained on bored piles in Flanders clay the other in the dense

sands of Dunkirk.

In the Flanders clay, as indicated above, the transition

between stable and unstable zones occurs very suddenly; it is

reflected by a single distinct line in the stability diagram of

Figure 19. This line reveals the dependence of the critical

loading threshold on the average load value. It has been verified

that in the regime of one-way tests, the threshold lies at high

values of Q

max

= Q

a

+Q

cy

(i.e. Q

max

/Q

uc

> 0.8). In the two-way

mode, the zone of instability could not be explored, leaving the

dashed line to appear like a conservative envelope highlighting

the stable zone.

The stability diagrams in sands were determined by setting the

static capacity measured just before the considered cyclic

sequence as the static reference load and then adopting a cyclic

pile failure criterion equal to 3% of relative displacement at the

top.

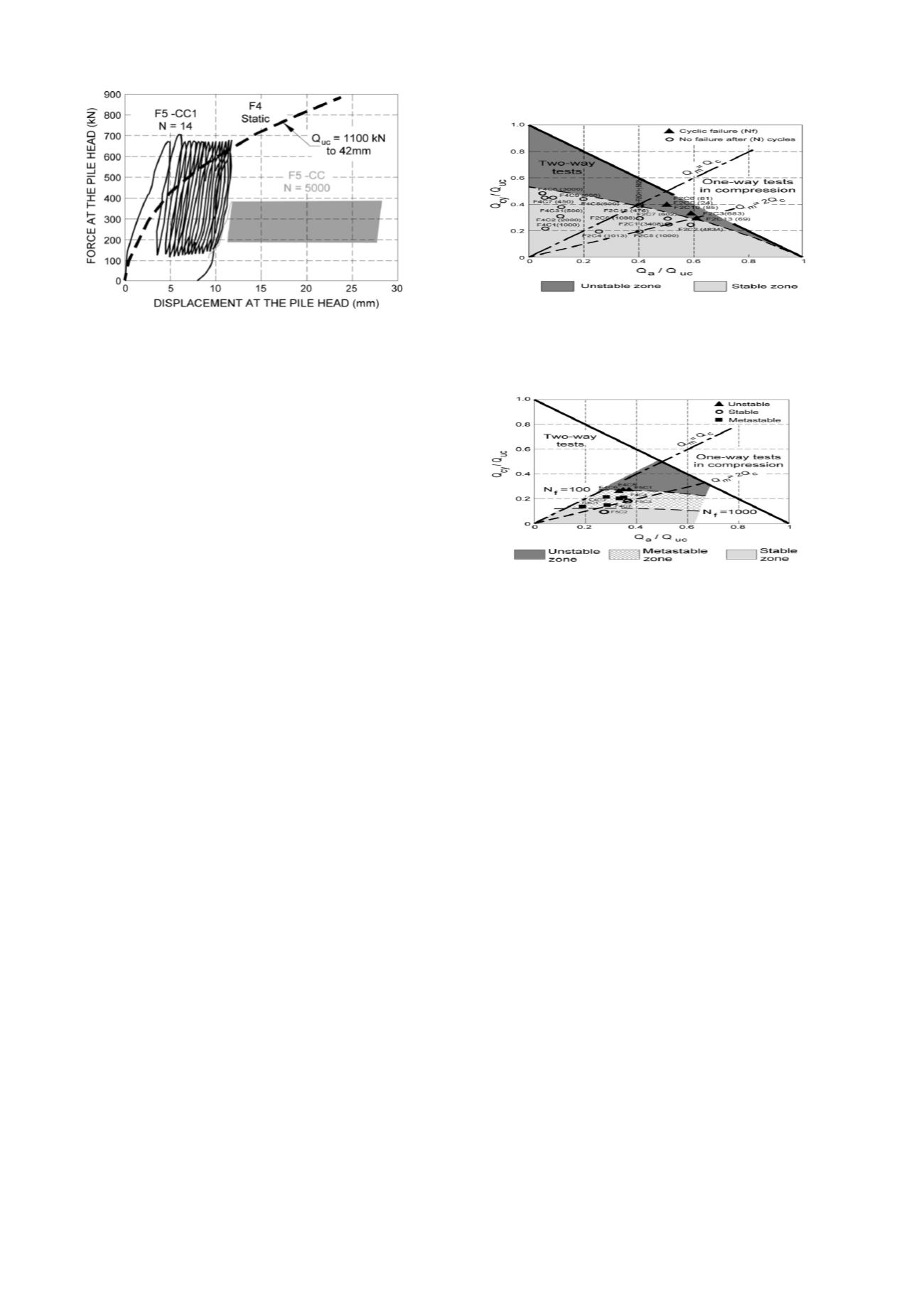

Fig. 19: Cyclic stability diagram for a pile bored in the overconsolidated

Flanders clay at the MERVILLE site (Benzaria, 2012)

Fig. 20: Cyclic stability diagram for a pile bored in dense Dunkirk sand

at Loon-Plage (Puech

et al.

, 2013)

Figure 20 shows the cyclic stability diagram of bored piles at

LOON-PLAGE (Puech

et al.

, 2013); it serves to define the three

following zones:

-

an

unstable

zone in which piles quickly progress towards

failure (N

f

< 100);

-

a

stable

zone corresponding to low-amplitude cyclic loadings

in which the piles are able to withstand over 1,000 cycles

without accumulating significant permanent displacements;

-

an intermediate, so-called

metastable

zone in which the pile

accumulates large displacements or reaches cyclic failure

between 100 and 1,000 cycles.

The greater sensitivity to cyclic loadings exhibited by sands is

clearly apparent. Let's note that a test series on model piles in a

centrifuge, where eight cast piles had been introduced into the

same container of dense Fontainebleau sand and loaded on a

one-time basis (i.e. a single static or cyclic test per pile), yielded

a stability diagram nearly identical to that of the LOON-PLAGE

bored piles.

The SOLCYP results reveal that the cyclic response of piles

depends to a greater or lesser extent on: pile type, soil

conditions, loading mode, and loading history.

8.2.5

Design methodology in the presence of cyclic axial loading

The comprehensive design of a pile subjected to cyclic axial

loadings might rely on a set of relatively complex procedures

that do not always need to be justified by day-to-day practices.

SOLCYP has favored proposing various approaches, in offering

increasing levels of complexity and developing criteria to

determine which level of analysis is the most appropriate given

the case under consideration.

The

cyclic stability diagram

, as described above, is a most

attractive tool for identifying the critical loading cases that

justify a specific and relatively in-depth analysis (Jardine

et al.

,

Volume 6 - Page 91