1837

Technical Committee 205 /

Comité technique 205

following section. The creep criterion is selected to represent a

ULS anchor resistance.

The UK currently excludes Section 8 of EC7 from use in

that country in its National Annex and requires anchors to be

designed to BS8081 ‘Ground Anchorages’. The design of

anchors in that standard is based on the ‘working load’,

T

w

,

which is defined as ‘The safe load of the anchorage’. No

guidance is given in the standard as to whether

T

w

is determined

using a ULS calculation or using characteristic values, however

the terminology would suggest that it was originally considered

to be similar to

F

Serv;k

. In practice, it is considered that for

embedded walls,

T

w

is taken as the higher of that obtained using

either a limit equilibrium or a bending moment and

displacement analysis using appropriate pressure distributions.

The proof load is related to

T

w

, as discussed in the following

section, with different creep criteria to be satisfied which can be

related to a SLS and to a ULS resistance.

Section 8 has not been specifically excluded in Ireland,

nevertheless the practice is generally to adopt the BS8081

testing criteria with

T

w

based on a calculation using

characteristic actions and parameters. However, given the

general lack of specific guidance in this area prior to the

publication of the amended Section 8, some designers also

considered the value of

F

ULS,d

in the selection of

T

w

if that gave

a greater value.

Denmark uses the present EC7, section 8.

The anchor force

is based on a ULS design force found from a calculation of the

anchored structure with factored soil parameters. Some Danish

designers compute a service load (

F

Serv;k

),which considers

prestress/lockoff of the anchor. This force is such as to resist a

ULS if

F

Serv;k

is greater than

F

ULS;d

. This means that

E

ULS;d

=

F

Serv;k

if

F

Serv;k

> F

ULS;d

. The Proof load is then based on

E

ULS;d

and must satisfy a limiting creep criterion. Previously Denmark

used the German test method as described in DIN 4125.

However, with the introduction of EN 1537:1999 Denmark has

accommodated the incomplete test specifications stated in the

informative annex E of EN 1537:1999. Test method 1 (TM1) is

preferred because of the relationship to the former DIN 4125,

but the creep rate limit measured in the acceptance test using

TM1 in EN1537:1999 is so strict (0,8 mm), that often Test

Method 3 (TM3) is adopted because of the more moderate creep

rate limit (1,2 mm). Temporary anchors may be loaded to a

lower proof load than permanent anchors, provided the

consequence of failure justifies that. Similarly the effect of high

or serious consequences of failure are governed by the

reliability class concept as described in EC0, Annex B by

introducing a

K

FI

factor applied to the partial safety factor on

the load or on the resistance.

4 TESTING OF ANCHORS

Load testing of anchors has historically been an intrinsic part of

the design and execution of anchors – in particular grouted

ground anchors - and the mandatory acceptance testing of all

grouted anchors is required in EN 1997-1:2004/prA1:2012 and

in EN 1537:1999. The anchors are loaded to a proof load (

P

p

)

to verify limit state design requirements. The tests are

categorised as:

1. Investigation Tests undertaken to establish the geotechnical

ultimate resistance,

R

ULS;m

, of the anchor at the grout/ground

interface and to determine the characteristics of the anchor

within the working load range.

2. Suitability tests – carried out on site on anchors identical to

those to be used in the works – to investigate some

characteristics of the anchor and how the anchor performs under

working conditions.

3. Acceptance tests – carried out on every anchor installed in

the permanent works – to ensure that each anchor will perform

as designed.

For Investigation and Suitability tests

P

p

is derived from:

P

p

≥ ξ

ULS

x

γ

a;ULS

x E

ULS;d

(8)

For Acceptance tests

P

p

is derived from

E

ULS;d

or

F

Serv;k

;

P

p

≥ γ

a;acc;ULS

x E

ULS;d

(9)

or

P

p

≥ γ

a;acc;SLS

x F

Serv;k

(10)

The method is to be stated in the National Annex of each

country.

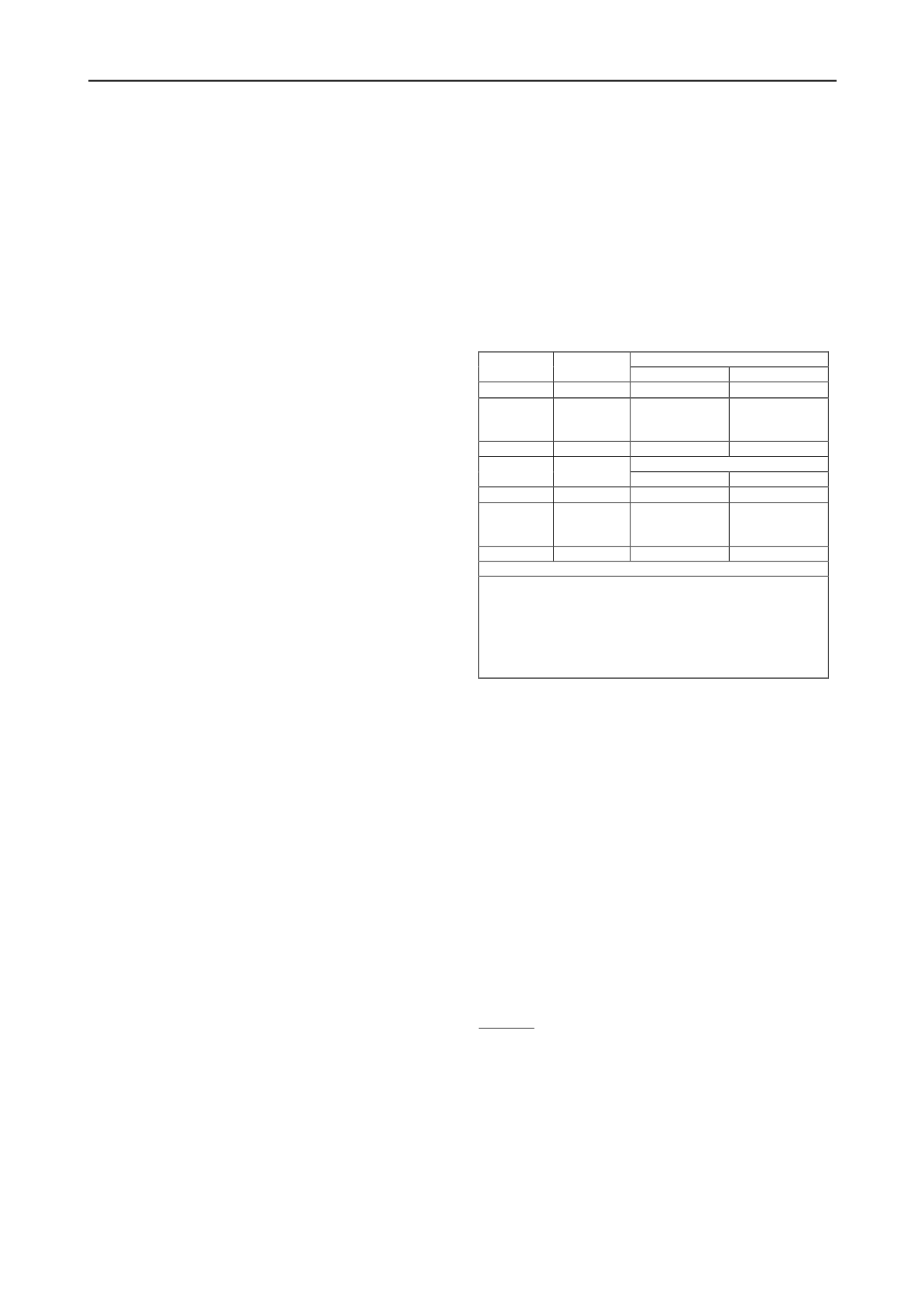

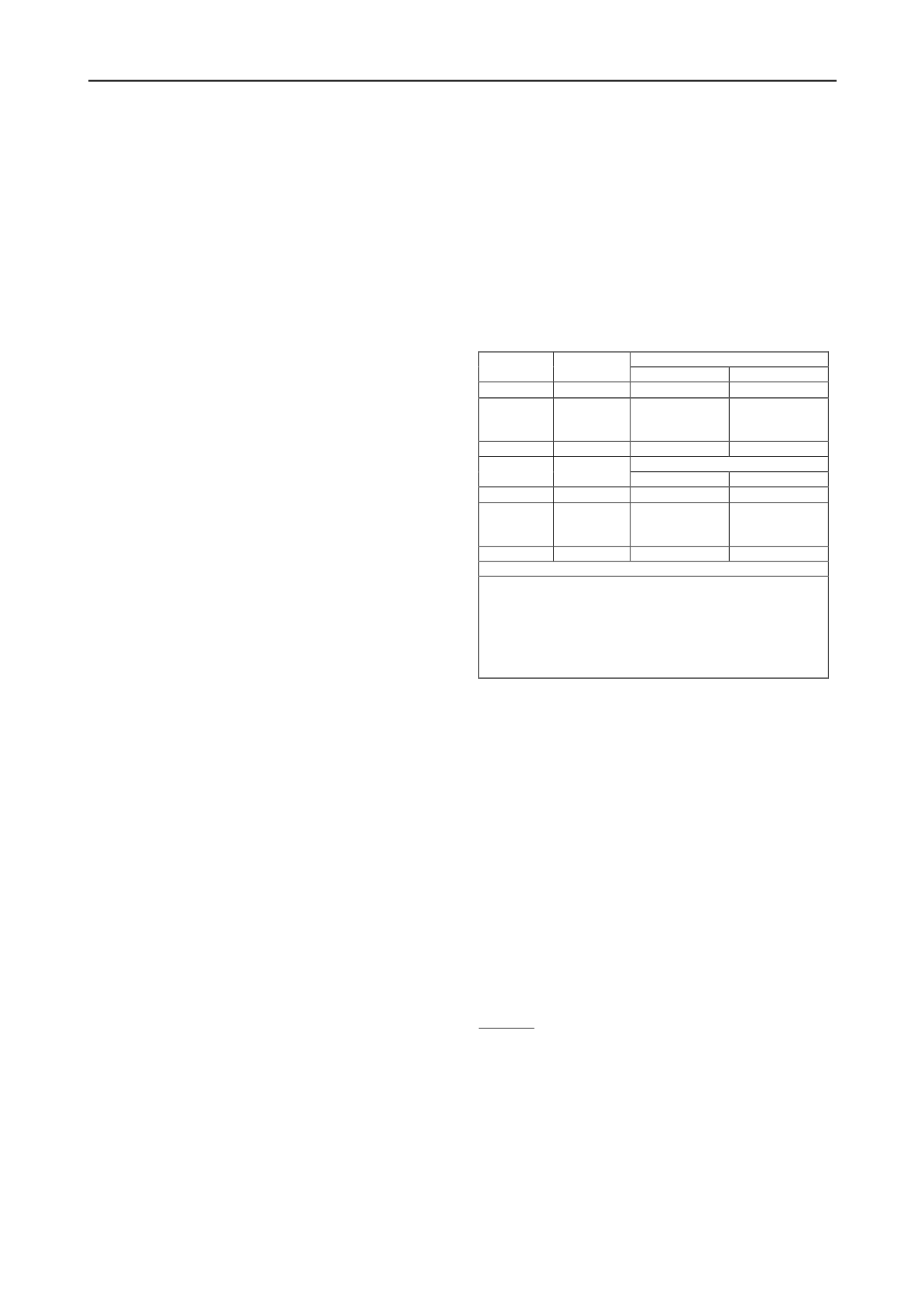

Table 1 - Limiting Criteria for investigation, suitability and acceptance

tests for persistent and transient design situations at the ultimate and

serviceability limit states (from EN 1997-1:2004/prA1:2012)

Test

Method

a

Limiting

criterion

Investigation and Suitability tests

ULS

SLS

1

α

1

2 mm

0.01

∆

e

b

2

k

l

(per log

cycle of

time)

2%

2%

3

α

3

5 mm

NA (use P

c

)

Test

Method

a

Limiting

criterion

Acceptance tests

ULS

SLS

1

α

1

2 mm

0.01

∆

e

2

k

l

(per log

cycle of

time)

2%

2%

3

α

3

NA

1.5 mm

c

Note: NA = Not applicable

a

Test methods are in accordance withDraft EN ISO 22477-5

Geotechnical investigation and testing - Testing of

geotechnical structures - Part 5: Testing of anchorages

b

∆

e

= (F

serv.k

x tendon free length)/(area of tendon x elastic

modulus of tendon)

c

Value given is for permanent anchors; for temporary

anchors,

α

3

= 1.8 mm

EN 1537:1999 provides for three methods to undertake the

suite of tests, essentially following the traditions in testing

developed and maintained in Germany, the UK and France. As

stated in section 3, these test methods are referred to as Test

Method 1, 2 and 3. This approach and test designation has been

implemented in EN 1997-1:2004/prA1:2012 and Draft EN ISO

22477-5 expected to be published in 2013.

The provisional limiting criteria for ULS and SLS resistance

for these tests to EN 1997-1:2004/prA1:2012 are given in Table

1. The methods of execution and interpretation of the tests are

to be found in Draft EN ISO 22477-5. This standard makes no

specific reference to testing for either SLS or ULS stating that

proof loads are to be set in accordance with EN1997-1. Not all

countries have the requirement to determine the limiting criteria

for SLS of the anchor as this is considered to be satisfied if the

test results meet the ULS criteria.

The test methods currently adopted in Germany, Denmark,

France, Ireland and the UK are summarised below. It should be

noted that some countries already use partial factors whilst

others still adopt a more global safety factor approach.

Germany.

1. Follow Test Method 1

2.

For all categories of test (investigation, suitability and

acceptance), proof load is:

P

p

=1,1 x 1,35 x F

Serv;k

(11)

or

P

p

=1.1 x F

ULS;d

(12)

3. Limiting criteria based on value of

α

1

for

investigation, suitability and acceptance tests.

Acceptance tests are required to satisfy the

α

1

criterion, but the test is shorter than that required for

suitability tests.