2132

Proceedings of the 18

th

International Conference on Soil Mechanics and Geotechnical Engineering, Paris 2013

was hinged at the bottom of the test box so as to allow lateral

displacement to occur during the wetting and drying process.

The backfill soil was a non-plastic poorly-graded sand,

commonly known as decomposed granite soils (DCG) in Korea,

classified as SP as per ASTM 2487 (ASTM 1992) with the

effective size (

D

10

), uniformity coefficient (

u

), and coefficient

of curvature (

c

) of 0.36 mm, 5.3 and 1.1, respectively. The

soil was compacted to 70% of its maximum unit weight

(

) to create reinforced as well as retained zones. The

estimated effective internal friction angle (

C

'

C

3

/

19

m kN

) using a series of

consolidated-undrained (CU) triaxial compression tests with

pore pressure measurements at a density corresponding to the

as-compacted state was determined as approximately 35

with a

shear stress intercept of 8 kPa.

(a) Test box (unit mm)

(b) photo of model GRSW

Figure 1. Test box and model GRSW

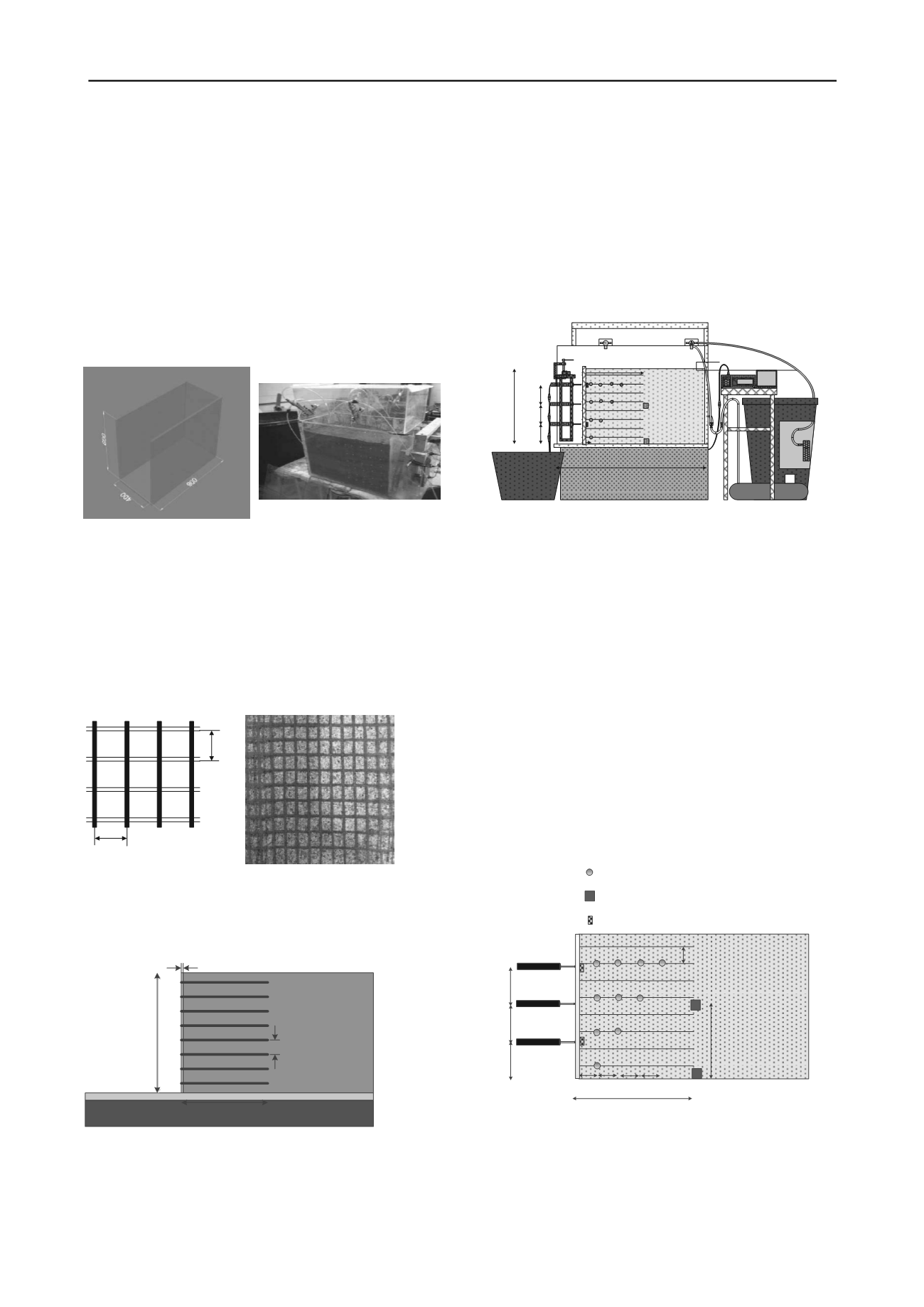

A non-woven geotextile was used as reinforcement. Note

however that the tensile strength of the non-woven geotextile

was intentionally reduced by creating 5 mm x 5 mm square

holes (Figure 2) to have an ultimate tensile strength of

. Six layers of reinforcement, 35 cm in length

each, were placed at a vertical spacing of 6 cm (Figure 3). The

reinforcement layers were firmly connected to the wall facing

by bolting.

m kN

/

10 8.3

2

(a) square hole size

(b) photo of model reinforcement

Figure 2. Model geotextile reinforcement

Figure 3. Schematic sectional view of model GRSW

2.2 Rainfall simulation

Three cycles of wetting and drying were applied to the model

walls to simulate the natural weather condition. Two rainfall

intensities ( ) were considered, i.e., 18.7 mm/h and 56.2 mm/h

for a given total precipitation of 450 mm. The duration of the

rainfall for the case with

was therefore 24 hours

while 8 hour duration was used for the case with

.

Note that these rainfall conditions were based on the actual

rainfall occurred in 2011 in Kyoung-Gi province, Korea.

Followed after each wetting process was a 24 hour drying

period prior to the ensuing wetting to observe the wall behavior

during the repeated wetting and drying.

r

I

h mm

I

r

/

7.18

2.56

h mm

I

r

/

2.56

The rainfall was simulated by spraying water at the top of

the backfill using spray guns with 15HP compressor and a 20W

water motor (Figure 4).

Data

Logger

Note

book

900

50

350

500

125

125

125

Unit: mm

Figure 4. Schematic diagram of rainfall simulator

2.3 Instrumentation

The performance of the model GRSW under a series of wetting

and drying cycles was evaluated in terms of wall facing

displacements, pore water pressures, and reinforcement strains.

The layout of instrumentation program is shown in Figure 5.

As shown, the horizontal displacements of the wall facing

were measured by using three LVDTs having gauge length of

100 mm, placed at locations along a vertical row. In addition,

the wetting and drying cycle induced reinforcement strains were

measured using high-elongation strain gauges, manufactured by

Tokyo Sokki Kenyujo Company (Model YFLA-5-5L) which

were mounted directly onto the selected reinforcement layers in

one array. Also installed at the back of the reinforced zone

were two pore pressure cells (Model BPR-A-200 kPa) at the

bottom (0 mm) and 250 mm above the wall base. The

volumetric water content of the backfill soil during the wetting

and the drying process was also measured using a tensiometer

(Model EC-5).

Unit [mm]

5

5

Figure 5. Instrumentation layout

3 RESULTS AND DISCUSSION

3.1 General behavior

Figure 6 show the measured data for the rainfall intensity of

. As mentioned, the

intensity rainfall

h mm

I

r

/

2.56

h mm

/

500

5

350

60

Unit : mm