2129

Technical Committee 207 /

Comité technique 207

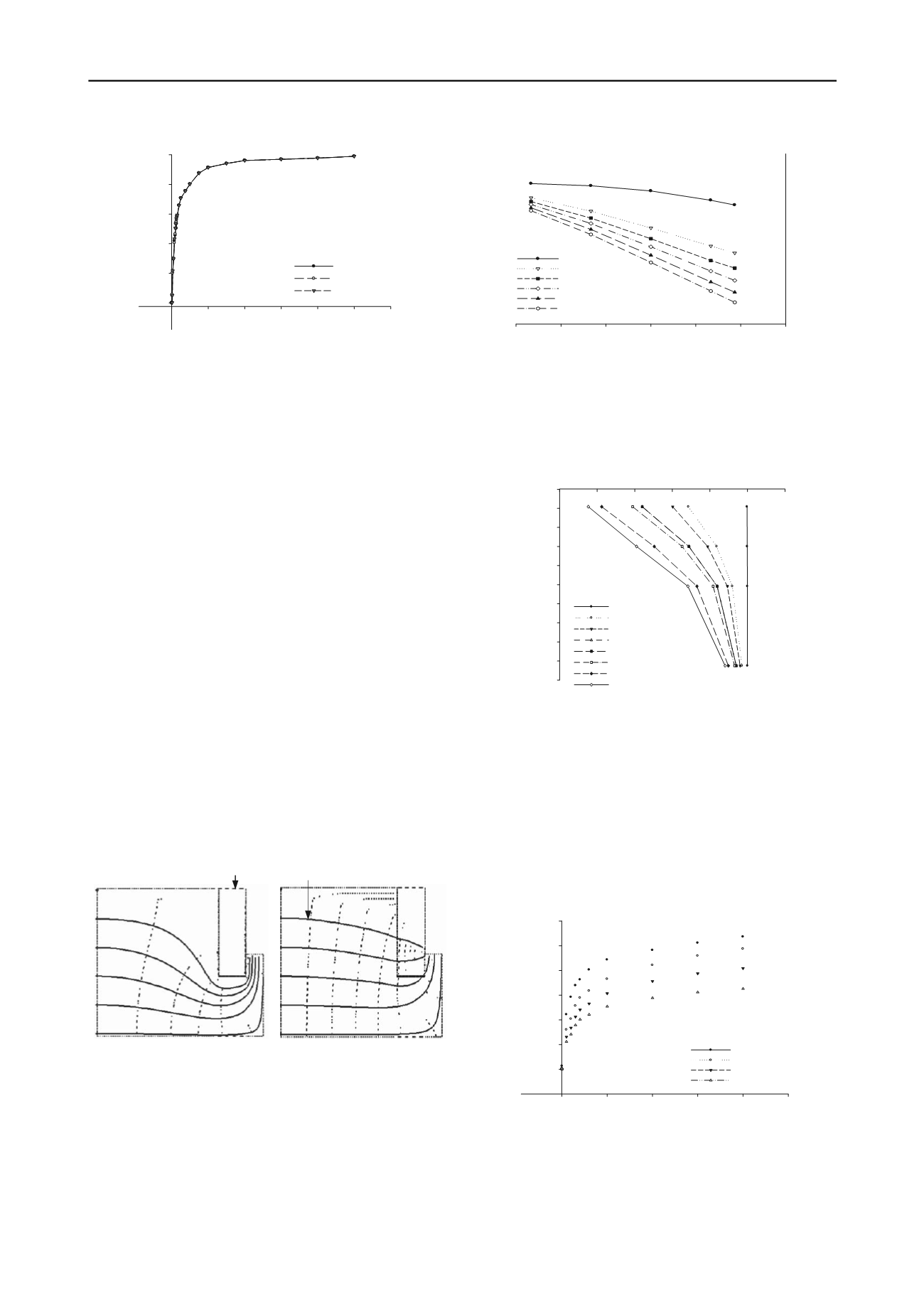

x/d

0

2

4

6

8

10

12

k

p

/k

s

0.0

0.2

0.4

0.6

0.8

1.0

U1 =5.4kPa

U2 =3.9kPa

U3 =2.4kPa

Figure 4. Calculated permeability from FLAC2D simulations.

2.3

Application of derived expression to 2D analyses

The aim of phase 2 simulations was to test the application of the

permeability expression derived in phase 1.

2.3.1

Procedure

A continuous wall was used to represent the contiguous pile

retaining wall. The model wall thickness (t) was calculated by

equating the second moments of area (I) of the different cross-

sections (A) as outlined by Powrie et al (1999) (Eq. 5). This

gave a result similar to the stiffness approach adopted by Day

and Potts (1993) (see Eq. 6 and 7).

m

I

p

I

(5)

EA tE

eq

(6)

EI

E

eq

(7)

where E

eq

and E are the equivalent model wall stiffness and

material Young’s modulus respectively.

The simulations commenced as before with a ‘wished into

place’ model wall. Pore pressures were varied corresponding to

U

i

as before for different pile gap to diameter ratios, x/d.

2.3.2

Results and discussion

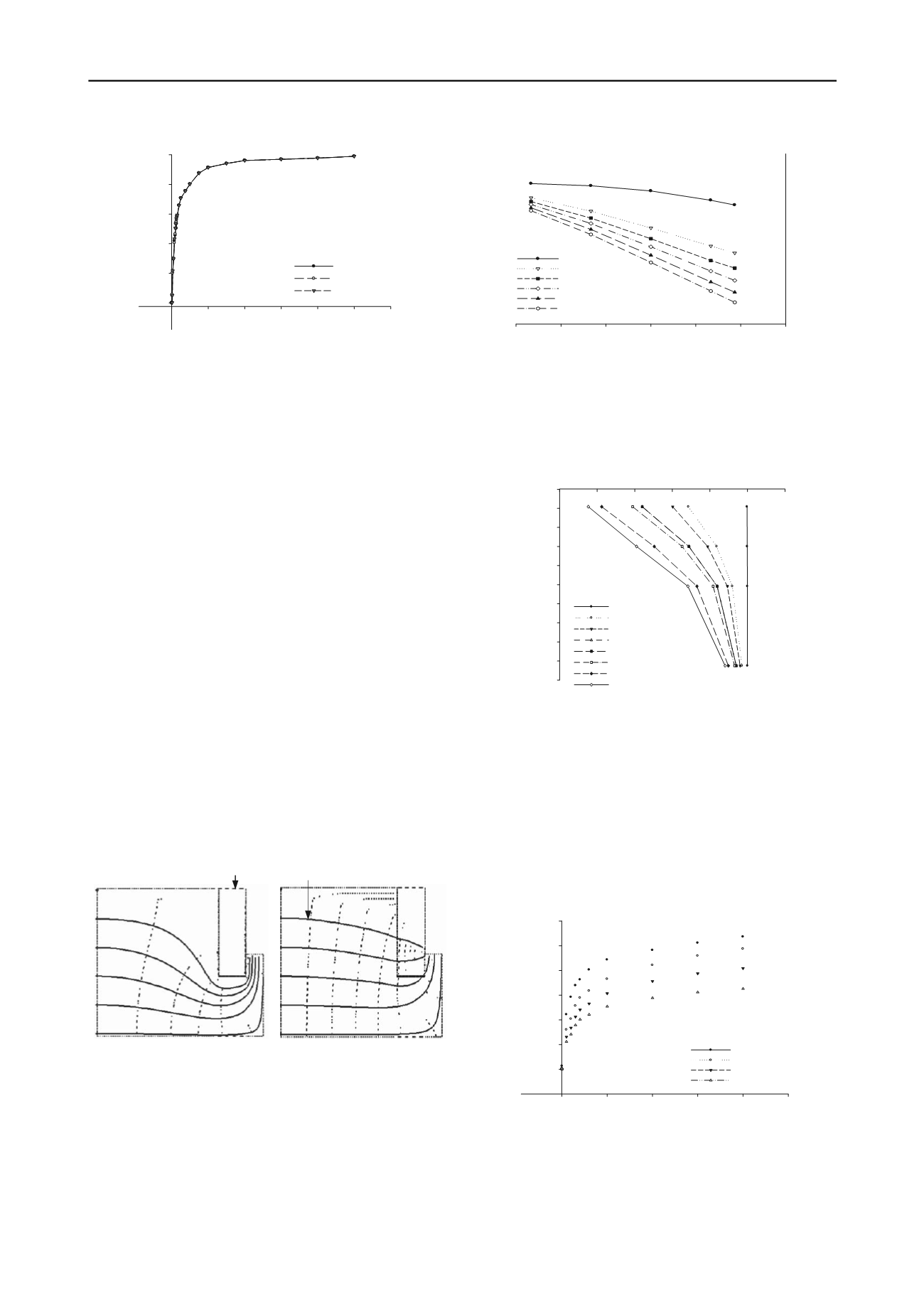

It was observed that flow patterns for the ‘permeable’ walls

deviated from the classically accepted flow around an

impermeable retaining wall especially at higher values of x/d.

This seems to suggest that through-wall flow is taking place for

x/d>0.0 as shown in figure 5.

Figure 5. Tracked flow-paths for x/d=0 and x/d=0.1. Note these are not

intended to be flownets, hence the flow elements are not “square”.

2.3.3

Pore pressure distribution

Pore pressures ratios P

i

/P

0

are plotted against normalized

distance (L/d) from the model wall in figure 6 for various values

of x/d.

Distance behind wall/pile diameter (l/d)

-3.5

-3.0

-2.5

-2.0

-1.5

-1.0

-0.5

Normalizedporepressure(P

1

/P

0

)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

x/d=0.05

x/d=0.15

x/d=0.3

x/d=0.5

x/d=1.0

x/d=2.0

Figure 6. Normalised pore pressures for different x/d against distance

(L/d) from the wall.

It was observed that pore pressures at each position behind

the wall decreased with x/d as the equivalent permeability

increased. Further analyses have shown that the pore pressures

and hence hydraulic head reduce towards the wall (Figure 7).

Normalised pore pressure (P

i

/P

0

)

0.0

0.2

0.4

0.6

0.8

1.0

1.2

Depth/pile length (Z/L

p

)

-2.4

-2.2

-2.0

-1.8

-1.6

-1.4

-1.2

-1.0

-0.8

-0.6

-0.4

x/d=0.001

x/d=0.05

x/d=0.1

x/d=0.2

x/d=0.2

x/d=0.3

x/d=1.0

x/d=2.0

Figure 7. Normalised pore pressure versus normalized depth below soil

surface for different values of x/d.

2.3.4

The effect of seepage on surface settlement

Surface settlements increased as the bulk permeability of the

wall increased (see Figure 8). The calculated settlement values

were compared with an estimated solution which uses the one

dimensional stiffness modulus (Roberts et al 2007). It was

noted that the 1D stiffness modulus method over-predicted

surface settlement at higher x/d as shown in Figure 9. This is

unsurprising as in this approach all volume change is assumed

to manifest as vertical settlement.

Pile gap to diameter ratio, x/d

0.0

0.5

1.0

1.5

2.0

2.5

Normalized settlement (S/S

0

)

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

0.67d behind

1.13d "

1.80d "

2.47d "

Figure 8. Normalised settlement increases with soil/structure

permeability.

Flow line

Wall

a)

b)